Advanced CNC Sewing Machines for Precision and Efficiency in Textile Manufacturing

The Evolution and Impact of CNC Sewing Machines in the Textile Industry

In recent years, technology has made significant strides in the textile industry, particularly with the introduction of CNC (Computer Numerical Control) sewing machines. These advanced machines have transformed traditional sewing methods, making the manufacturing process more efficient, precise, and cost-effective. This article delves into the evolution of CNC sewing machines and their profound impact on the textile landscape.

The Evolution of CNC Sewing Machines

The journey of sewing machines began in the 19th century with the invention of the first functional sewing machine by Elias Howe in 1846. However, it wasn’t until the advent of computer technology in the late 20th century that the concept of CNC sewing machines emerged. By incorporating computerized controls, manufacturers could program machines to perform complex sewing tasks with remarkable accuracy.

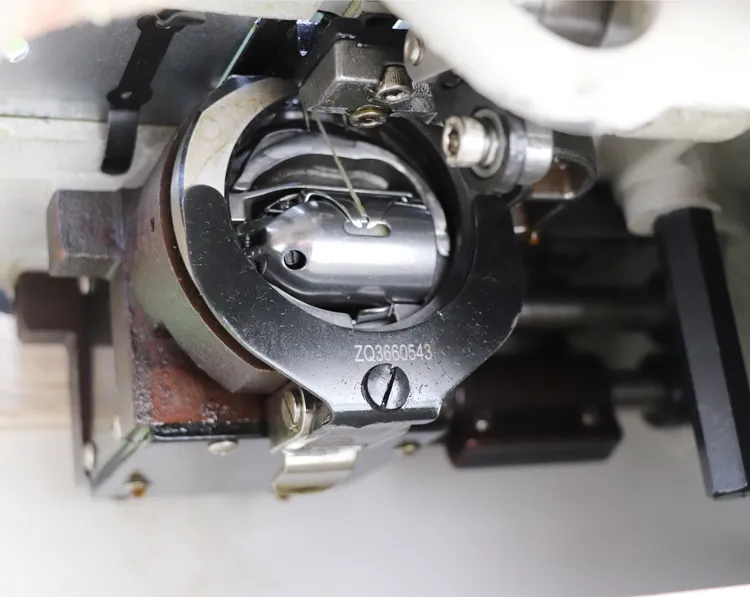

Early CNC sewing machines were primarily utilized in high-volume production settings where consistency and speed were paramount. As the technology advanced, features such as automatic thread cutting, contour sewing, and multi-needle capabilities were integrated. Modern CNC sewing machines are equipped with sophisticated software that allows designers to create intricate patterns and designs easily, significantly enhancing the creative possibilities within the textile industry.

Efficiency and Precision

One of the standout features of CNC sewing machines is their ability to achieve high levels of efficiency and precision. These machines can sew at high speeds, often exceeding the capabilities of manual sewing. This efficiency is essential for manufacturers looking to meet the demands of fast fashion and mass production.

Moreover, the precision of CNC machines ensures that each piece produced adheres to the exact specifications set by designers and manufacturers. In traditional sewing, human error can lead to inconsistencies in sewing patterns, resulting in wasted materials and increased production costs. CNC machines mitigate this issue by executing complex designs with exact repeatability, thus ensuring that every item meets the required standards.

cnc sewing machine

Economic Impact

The implementation of CNC sewing machines has considerable economic implications for the textile industry. While the initial investment in CNC technology can be significant, the long-term benefits often outweigh the costs. By increasing production efficiency and reducing waste, companies can lower their operational costs. This economic viability allows manufacturers to pass savings on to consumers, ultimately making products more competitive in the market.

Additionally, CNC sewing machines enable manufacturers to respond more swiftly to changing fashion trends. They can quickly shift production lines to create new styles, reducing the turnaround time significantly. This agility is crucial in an industry where trends come and go rapidly.

Challenges and Future Prospects

Despite the advantages, the shift to CNC sewing machines does present challenges. The need for skilled operators who can program and maintain these machines is imperative. Additionally, the integration of CNC technology may displace some traditional sewing jobs, leading to concerns about workforce stability.

However, the future of CNC sewing machines looks promising. As technology continues to advance, we can expect further innovations in automation, artificial intelligence, and machine learning that will enhance the capabilities of sewing machines. These advancements could lead to even more streamlined production processes and innovative design possibilities.

Conclusion

CNC sewing machines have revolutionized the textile industry by bringing efficiency, precision, and economic advantages to manufacturers. As technology continues to evolve, we can anticipate even greater developments that will further modify the landscape of apparel production. Embracing these changes is essential for manufacturers seeking to thrive in a competitive market, making CNC sewing machines an indispensable tool for the future of fashion and textiles.

-

Boost Production Efficiency with a Pattern Sewing MachineNewsAug.29,2025

-

Industrial Excellence with the Best Heavy Duty Sewing MachineNewsAug.29,2025

-

Precision and Power with the Best Pattern Sewing MachineNewsAug.29,2025

-

Reliable Bulk Packaging Starts With the Right FIBC Sewing MachineNewsAug.29,2025

-

Advanced Packaging Solutions: Elevate Productivity with Jumbo Bag Sewing Machine and Industrial Stitching EquipmentNewsAug.29,2025

-

High-Performance Solutions for Bulk Packaging: FIBC Sewing Machine and MoreNewsAug.29,2025

-

Maximize Efficiency with an Industrial Cylinder Arm Sewing MachineNewsAug.28,2025