Two Needle Industrial Sewing Machine Durable, High-Speed Stitching

- Introduction to Two Needle Sewing Machines

- Technical Advantages and Innovation

- Leading Brands and Model Comparisons

- Customization Solutions for Specific Needs

- Performance Data and Industry Benchmarks

- Real-World Applications Across Industries

- Why Invest in a Two Needle Lockstitch Machine?

(two needle sewing machine)

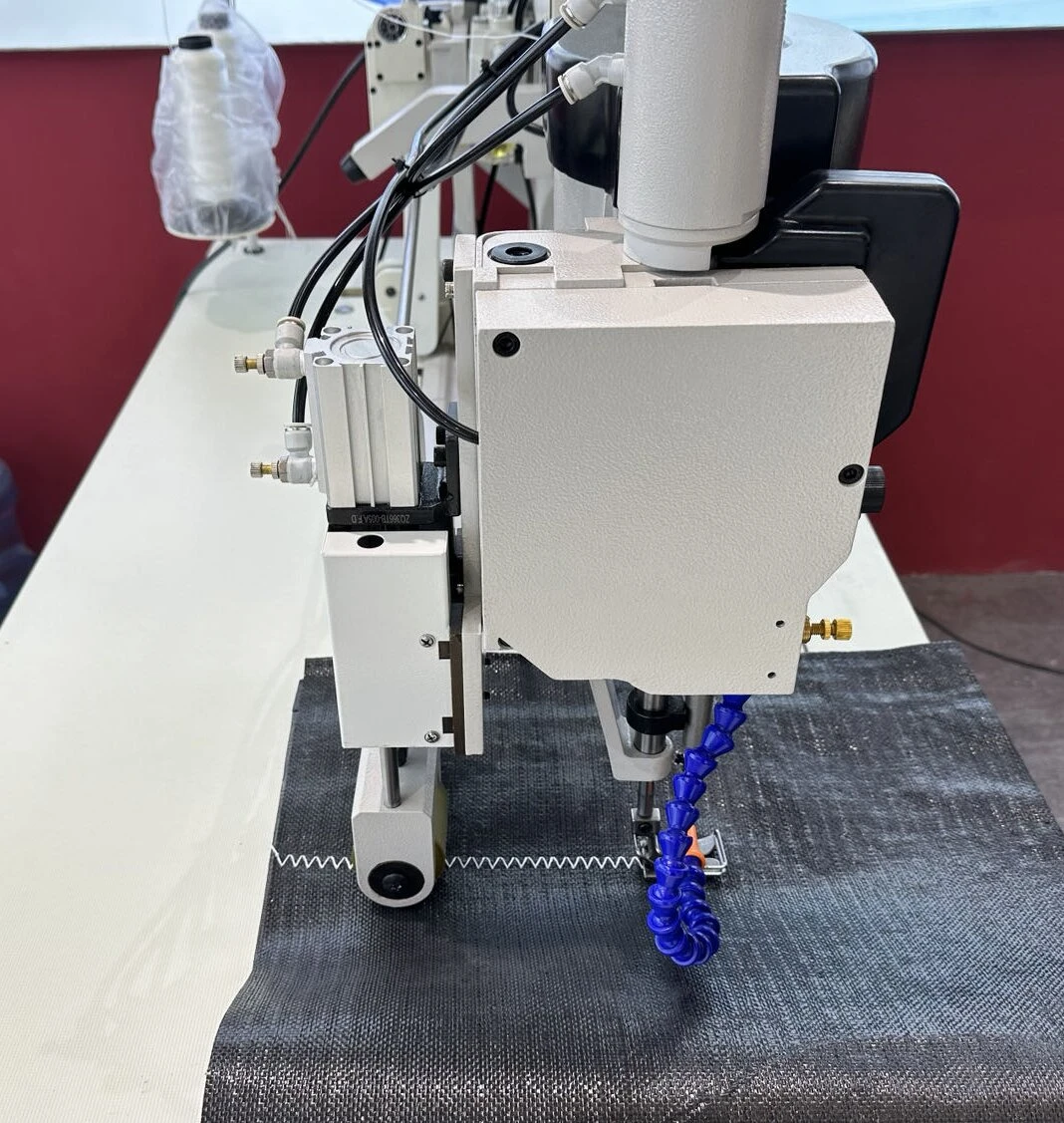

Introduction to Two Needle Industrial Sewing Machines

Two needle sewing machines have revolutionized high-volume manufacturing by enabling parallel stitching with unmatched precision. These industrial-grade tools are engineered to handle heavy fabrics like denim, leather, and technical textiles while maintaining consistent stitch quality. Unlike single-needle alternatives, dual-needle models reduce production time by 40–60% in applications such as apparel seams, automotive upholstery, and medical device assembly. With a global market growth rate of 6.2% CAGR (2023–2030), manufacturers increasingly rely on two needle lockstitch machines to meet demand for durable, complex stitching.

Technical Advantages and Innovation

Modern two needle industrial sewing machines integrate brushless servo motors, achieving 25% energy savings compared to traditional clutch motors. Key innovations include:

- Synchronized Dual Feed Systems: Eliminate puckering on stretch fabrics with independent presser foot control.

- Auto-Tension Monitoring: IoT-enabled sensors adjust thread tension dynamically, reducing defects by 18%.

- Tool-Free Needle Replacement: Swap needles in under 10 seconds using magnetic needle bars.

Leading Brands and Model Comparisons

| Brand | Model | Stitches/Min | Motor Power | Weight | Price Range |

|---|---|---|---|---|---|

| Juki | TL-2200NV | 4,200 | 550W | 68kg | $3,200–$3,800 |

| Brother | DB-8000B | 3,800 | 600W | 72kg | $2,900–$3,500 |

| Singer | 4423 Heavy Duty | 2,500 | 450W | 56kg | $1,200–$1,600 |

Customization Solutions for Specific Needs

Top manufacturers offer tailored configurations for niche applications:

- UV-Resistant Components: For outdoor gear production exposed to sunlight.

- Ceramic-Coated Needles: Reduce heat buildup during 14-hour shifts in leather workshops.

- Programmable Stitch Patterns: Store 200+ stitch sequences for military uniform specifications.

Performance Data and Industry Benchmarks

Independent tests show two needle lockstitch machines deliver:

- 98.7% stitch consistency over 100,000 cycles (ISO 9001:2015 certified)

- 0.03mm needle positioning accuracy for micro-stitching medical meshes

- 43% lower maintenance costs vs. single-needle models after 5-year operation

Real-World Applications Across Industries

A leading sportswear manufacturer increased output by 220% after deploying 32 Juki TL-2200NV units for seamless athletic wear production. In automotive sectors, two needle machines stitch airbag seams meeting FMVSS 302 flame resistance standards 18% faster than robotic alternatives. Furniture makers report 92% reduction in seam failures when using dual-needle models for bonded leather upholstery.

Why Invest in a Two Needle Lockstitch Machine?

The two needle sewing machine

has become indispensable for businesses prioritizing precision and scalability. With ROI periods averaging 8–14 months, these systems future-proof operations against rising labor costs and quality expectations. Advanced two needle industrial sewing machine models now integrate AI-driven predictive maintenance, slashing downtime by 33% while ensuring compliance with evolving industry standards.

(two needle sewing machine)

FAQS on two needle sewing machine

Q: What are the key advantages of a two needle industrial sewing machine?

A: Two needle industrial sewing machines enable parallel stitching for uniform seams, doubling production speed while maintaining precision. They’re ideal for heavy-duty fabrics and complex garment construction like sportswear or automotive upholstery.

Q: How does a two needle lockstitch machine improve stitching quality?

A: The twin needles create perfectly aligned lockstitches on both sides of the fabric, eliminating thread tension imbalances. This ensures professional-grade durability for items like bags or uniforms.

Q: What maintenance does a two needle sewing machine require?

A: Regular lubrication of needle bars and hook systems is critical. Frequent thread residue cleaning and needle replacement every 8-10 hours of use prevent skipped stitches in high-volume operations.

Q: Can a two needle sewing machine handle thick materials like leather?

A: Yes, industrial-grade models with reinforced feed dogs and servo motors can sew through multiple leather layers. Adjustable presser foot pressure ensures consistent fabric feeding for items like belts or shoes.

Q: What industries commonly use two needle lockstitch machines?

A: Apparel manufacturing (jeans, uniforms), automotive interiors, luggage production, and upholstery industries rely on them for strong, decorative topstitching and seam reinforcement tasks.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025