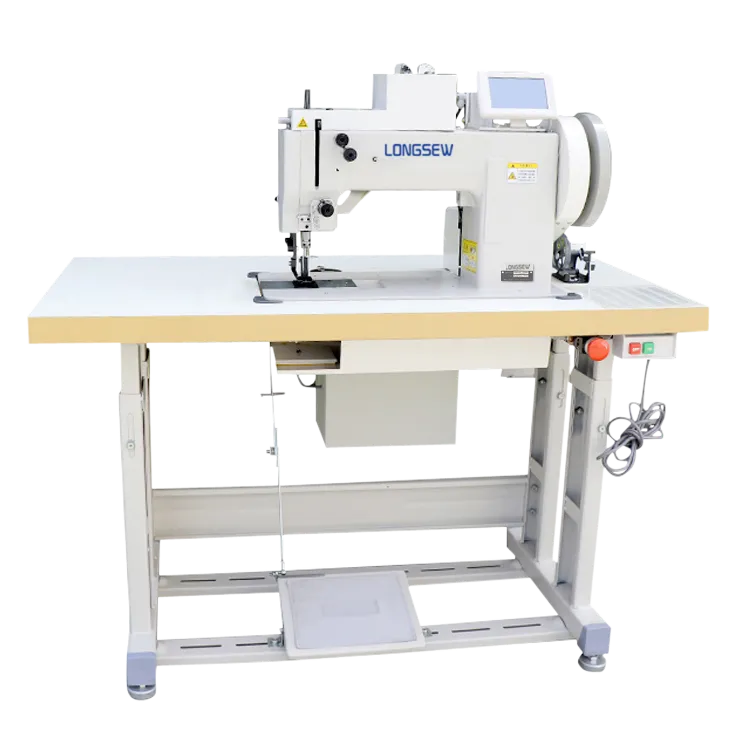

pp bag stitching machine

The Rise of PP Bag Stitching Machines A Game Changer in the Packaging Industry

In today's fast-paced manufacturing environment, efficiency and cost-effectiveness are paramount, particularly in the packaging industry. One of the most significant innovations to emerge in recent years is the PP bag stitching machine. These machines have revolutionized the way polypropylene (PP) bags are produced and sealed, providing a solution that is both durable and economical.

Understanding Polypropylene Bags

Polypropylene bags are widely used for packaging a variety of products, including agricultural goods, chemicals, and construction materials. Their strength and resistance to moisture make them an ideal choice for both industrial and commercial applications. However, the challenge has always been in how these bags are sealed efficiently to ensure they withstand transport and handling.

This is where the PP bag stitching machine comes into play. It is designed to stitch the open ends of PP bags securely, providing a tight closure that prevents spillage and contamination, ensuring that the contents remain safe during storage and transport.

The Mechanics Behind PP Bag Stitching Machines

PP bag stitching machines utilize advanced technology to deliver high-speed stitching with minimal operator intervention. Most modern machines are equipped with features like automatic threading, stitch counting, and speed control, allowing for precision and flexibility in production.

The stitching process typically involves a series of needles that penetrate the bag material and create a secure lock using heavy-duty thread. This not only provides a robust closure but also enables manufacturers to customize the stitching pattern based on their needs.

Furthermore, these machines are often designed to accommodate various bag sizes and types, enhancing their versatility on the production floor. Some models even come with additional features like integrated bag handling systems, making them a comprehensive solution for bag sealing.

Advantages of Using PP Bag Stitching Machines

pp bag stitching machine

1. Efficiency One of the key benefits of PP bag stitching machines is their speed. Many machines can stitch hundreds of bags per hour, significantly increasing productivity. This rapid output is vital for companies looking to meet high demands in a competitive market.

2. Cost-Effectiveness The initial investment in a PP bag stitching machine can be recovered quickly through savings in labor and material costs. They reduce the need for manual stitching, which can be time-consuming and prone to errors.

3. Durability The stitching produced by these machines is often stronger than traditional sealing methods such as heat sealing. This means that bags are less likely to burst or fail, leading to decreased product loss and increased customer satisfaction.

4. Customization Manufacturers can choose various stitching techniques and patterns to meet specific requirements. This flexibility makes it easier to align with branding and product specifications.

5. Reduced Waste Efficient stitching minimizes the amount of excess material used, which is not only cost-effective but also better for the environment. As sustainability becomes more important in manufacturing, this is a significant advantage.

The Future of PP Bag Stitching Technology

As the packaging industry continues to evolve, so too will PP bag stitching machines. Innovations in automation, artificial intelligence, and material sciences are expected to further enhance their capabilities. For instance, future machines may integrate smart technology that allows for real-time monitoring and adjustment, optimizing performance and reducing downtime.

Moreover, with the growing emphasis on sustainability, manufacturers are likely to explore biodegradable options for bag production. PP bag stitching machines will need to adapt to accommodate these new materials, ensuring they remain at the forefront of the packaging sector.

Conclusion

The PP bag stitching machine is more than just a piece of equipment; it represents a significant advancement in packaging technology. By delivering speed, durability, and cost-effectiveness, these machines are helping businesses thrive in an increasingly demanding marketplace. As we look to the future, the continued evolution of these machines will undoubtedly play a crucial role in shaping the packaging industry, ensuring that it meets the needs of both manufacturers and consumers alike.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025