pp woven bag cutting sewing machine

The Versatility of PP Woven Bag Cutting and Sewing Machines

In the thriving world of packaging solutions, polypropylene (PP) woven bags have become a household name due to their durability, water resistance, and eco-friendliness. Industries across the globe, including agriculture, construction, and retail, rely heavily on these bags for packaging their products. To meet the high demand for PP woven bags, businesses need efficient and reliable machinery. This is where PP woven bag cutting and sewing machines come into play, revolutionizing the production process.

The Versatility of PP Woven Bag Cutting and Sewing Machines

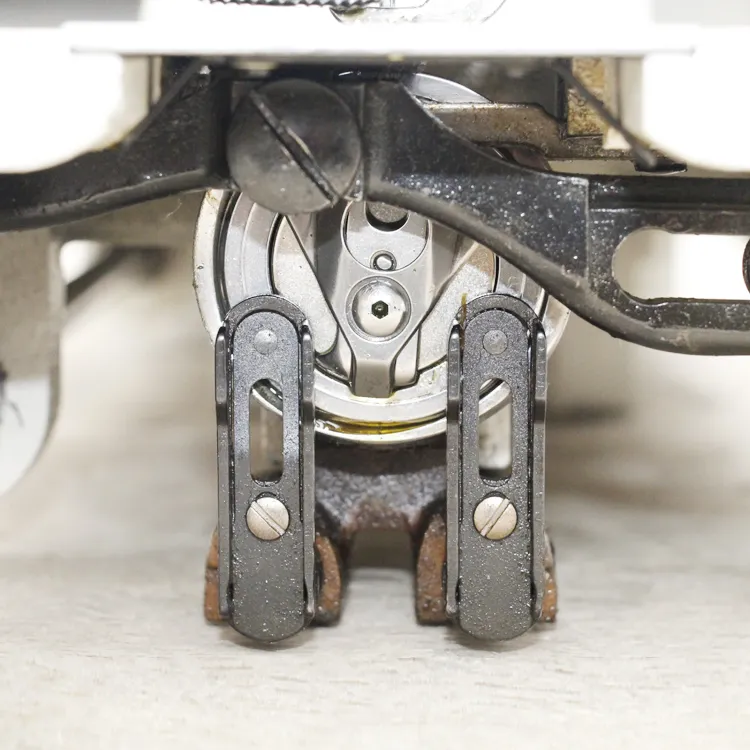

Once the fabric is cut into the desired dimensions, the next step involves sewing the pieces together. Modern PP woven bag sewing machines utilize state-of-the-art technology to deliver high-quality seams that withstand various weights and conditions. Many sewing machines are equipped with automatic thread trimming and edging features, which ensure that each bag is completed to perfection without manual intervention. This automation not only increases production speed but also improves product quality, making these machines indispensable in the packaging industry.

pp woven bag cutting sewing machine

Moreover, the versatility of these machines allows manufacturers to produce a wide range of bag styles. From simple shopping bags to complex multi-compartment designs, the ability to switch between different configurations opens a world of possibilities for businesses. This adaptability is especially beneficial in meeting customer demands for custom sizes and designs, allowing companies to cater to a broader market.

In addition to their operational efficiency, PP woven bag cutting and sewing machines are also designed with user safety and ease of operation in mind. Many models come equipped with digital interfaces that simplify the setup process and allow operators to monitor production progress in real-time. This user-friendly design decreases the likelihood of errors and enhances overall productivity.

As environmental concerns continue to gain traction globally, the low environmental impact of PP woven bags adds to their appeal. Made from recyclable materials, these bags offer a sustainable alternative to traditional packaging options. The production machines not only support this eco-friendly initiative but also contribute to the circular economy by maximizing the use of recyclable resources.

In conclusion, PP woven bag cutting and sewing machines play a pivotal role in the manufacturing process of one of today's most popular packaging solutions. Their efficiency, adaptability, and commitment to quality make them essential tools for businesses aiming to thrive in the competitive packaging industry. As demand continues to soar, investing in advanced cutting and sewing technology is not just a choice; it’s a necessity.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025