лют . 17, 2025 13:56

Back to list

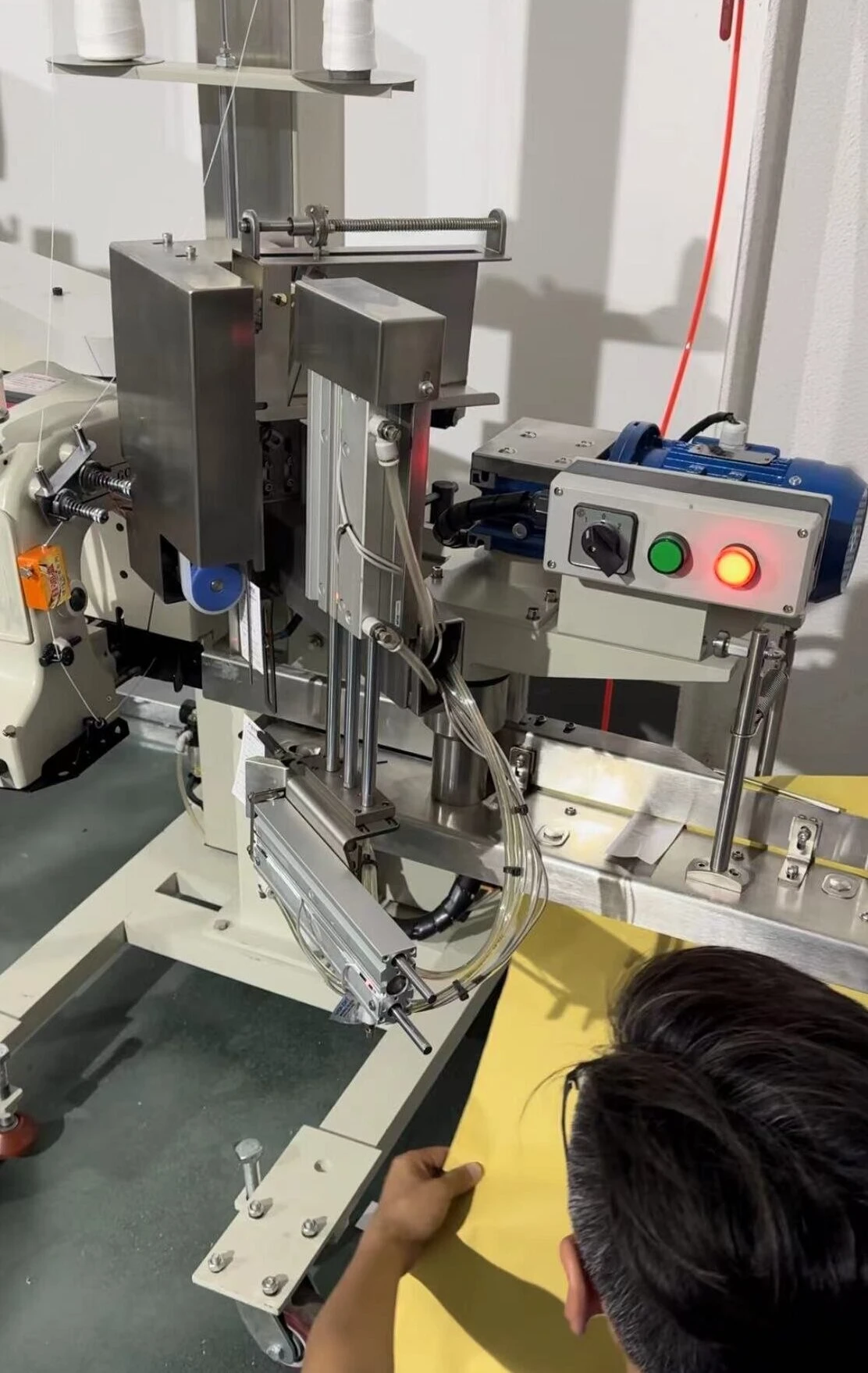

FIBC Bag / Jumbo Bag / Bulk Bag Single Needle Lock Stitch Top & Bottom Feeding Sewing Machine GSC367 /GSC367TD /GSC367TDZ/ GSC367-L

The needle feed sewing machine represents a pivotal innovation in industrial sewing, targeting efficiency and precision to meet the demands of modern garment manufacturers. A deep dive into the functionality of needle feed sewing machines reveals the advantageous integration of technology and traditional craftsmanship, especially for the production of exceptionally high-quality fabrics.

Trustworthiness in the do-main of needle feed sewing machines hinges on the verifiable improvements in garment quality corroborated by user testimonials and longitudinal studies within textile factories. Users frequently cite extended machine lifespans and lower maintenance requirements as tangible benefits backed by manufacturer guarantees and third-party reviews. Moreover, comparisons in studies highlighting productivity rates before and after implementing these machines underscore their dependable performance and reliability. For businesses seeking to stay ahead in the competitive garment manufacturing landscape, investing in needle feed sewing technology is not just about acquiring new machinery, but an endeavor to leverage cutting-edge engineering to enhance product quality. The tangible outcomes tied to these machines, such as smoother textile handling, precise stitching, and reduced operational risks, are persuasive arguments for stakeholders. Making an informed decision involves scrutinizing brand history for those manufacturers with a solid track record of innovation and dependability. Capitalizing on the capabilities of needle feed sewing machines can also be a stepping stone towards achieving higher certification standards, recognizing organizations not only for their superior product lines but also for operational excellence. These machines enable adherence to international garment standards, thereby expanding avenues for global trade partnerships and elevating brand reputation. In conclusion, a needle feed sewing machine offers more than technological advancement; it is a testament to a legacy of innovation designed to meet ever-evolving industry demands. Its role extends beyond a tool to being integral to the strategic growth and efficiency objectives of manufacturers dedicated to quality and operational excellence. This commitment ultimately translates into a stronger global standing and consumer trust, essential ingredients in the competitive textile industry.

Trustworthiness in the do-main of needle feed sewing machines hinges on the verifiable improvements in garment quality corroborated by user testimonials and longitudinal studies within textile factories. Users frequently cite extended machine lifespans and lower maintenance requirements as tangible benefits backed by manufacturer guarantees and third-party reviews. Moreover, comparisons in studies highlighting productivity rates before and after implementing these machines underscore their dependable performance and reliability. For businesses seeking to stay ahead in the competitive garment manufacturing landscape, investing in needle feed sewing technology is not just about acquiring new machinery, but an endeavor to leverage cutting-edge engineering to enhance product quality. The tangible outcomes tied to these machines, such as smoother textile handling, precise stitching, and reduced operational risks, are persuasive arguments for stakeholders. Making an informed decision involves scrutinizing brand history for those manufacturers with a solid track record of innovation and dependability. Capitalizing on the capabilities of needle feed sewing machines can also be a stepping stone towards achieving higher certification standards, recognizing organizations not only for their superior product lines but also for operational excellence. These machines enable adherence to international garment standards, thereby expanding avenues for global trade partnerships and elevating brand reputation. In conclusion, a needle feed sewing machine offers more than technological advancement; it is a testament to a legacy of innovation designed to meet ever-evolving industry demands. Its role extends beyond a tool to being integral to the strategic growth and efficiency objectives of manufacturers dedicated to quality and operational excellence. This commitment ultimately translates into a stronger global standing and consumer trust, essential ingredients in the competitive textile industry.

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025