Long Arm Sail Production Equipment for Efficient Marine Fabrication

Innovations in Long Arm Sail Making Machines

Sailing enthusiasts and marine industry professionals understand the significance of high-quality sails in optimizing performance and enhancing the overall sailing experience. A critical component in sail production has been the evolution of long arm sail making machines, which have redefined efficiency and precision in the manufacturing process.

Traditionally, sail making was a labor-intensive process that required considerable manual effort. Craftsmen would painstakingly cut, sew, and assemble sails using rudimentary tools. This not only consumed immense time but also left room for human error. The advent of long arm sail making machines has revolutionized this craft, making production faster and more accurate, while maintaining the integrity and quality of the sails.

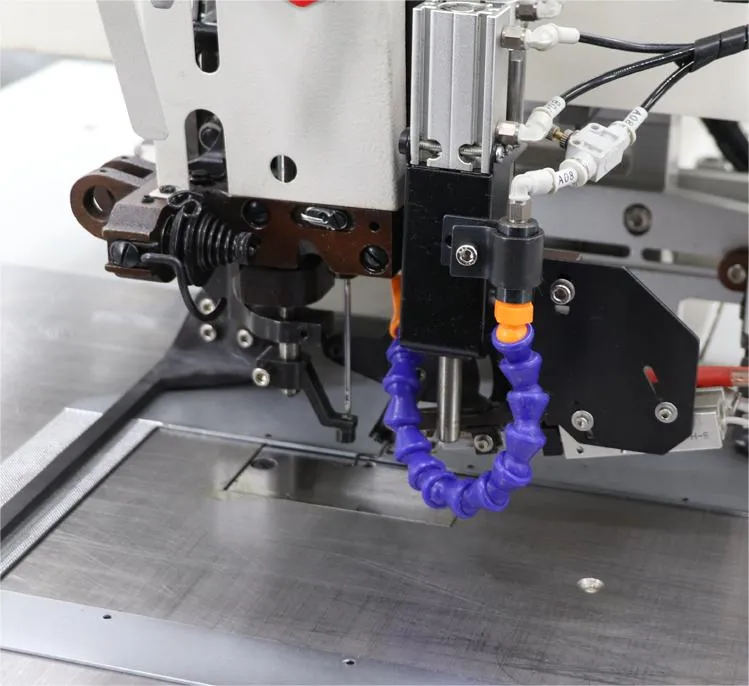

Long arm sail making machines are designed with extended sewing arms, which allow for the manipulation of larger fabric pieces—crucial for sail construction. These machines offer various innovative features such as automatic fabric feeding, adjustable stitch lengths, and programmable patterns. By utilizing these advanced technologies, manufacturers can produce sails that are meticulously crafted to meet the specific demands of different sailing conditions.

long arm sail making machine

One of the most significant advantages of these machines is their ability to handle heavy and bulky fabrics. Sails are typically made from robust materials like Dacron or Mylar, which require substantial force and precision to stitch effectively. The long arm design enables operators to work with larger sections of material without the limitations posed by standard sewing machines, which struggle to accommodate the bulkiness of sail fabrics. This capability not only enhances production speed but also ensures that the seams are strong and durable, which is essential for withstanding the harsh marine environment.

Moreover, the integration of computer-aided design (CAD) technology with long arm sail making machines has taken customization to new heights. Sail makers can now design intricate patterns and shapes digitally, which can be directly translated into the sewing machine's programming. This level of precision ensures that each sail is tailored to the specific needs of the vessel and the preferences of the sailor. The possibility of rapid prototyping through this technology allows businesses to respond quickly to customer demands and market trends, creating a more dynamic and responsive production line.

Sustainability in sail making has also benefited from advancements in long arm sail making machinery. Many manufacturers are increasingly focused on using eco-friendly materials and processes. With the ability to optimize fabric usage and reduce waste, these machines not only promote sustainability but also help in reducing production costs. By utilizing technology that minimizes leftover fabric and enhances recycling efforts, the sail making industry is moving towards a greener future.

In conclusion, long arm sail making machines have transformed the landscape of sail manufacturing by combining efficiency, precision, and sustainability. As technology continues to evolve, we can expect further innovations that will enhance the sail making process, paving the way for even more exciting advancements in the sailing world. For both manufacturers and sailing aficionados, the ongoing improvements in these machines promise a brighter future, with sails that not only perform exquisitely but are also produced with a mindfulness toward our planet. As we sail into this new era, the harmony between technology and craftsmanship will undoubtedly elevate the art of sail making to unprecedented heights.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025