Jumbo Petal Closure Sew Heavy-Duty FIBC Bag Seam Solutions

- Overview of Jumbo Petal Closure Sew Solutions

- Technical Advantages in Heavy-Duty Fabrication

- Competitor Comparison: Performance Metrics

- Customization for Industry-Specific Needs

- Real-World Applications Across Sectors

- Operational Cost-Benefit Analysis

- Future Outlook in Bulk Material Handling

(jumbo petal closure sew)

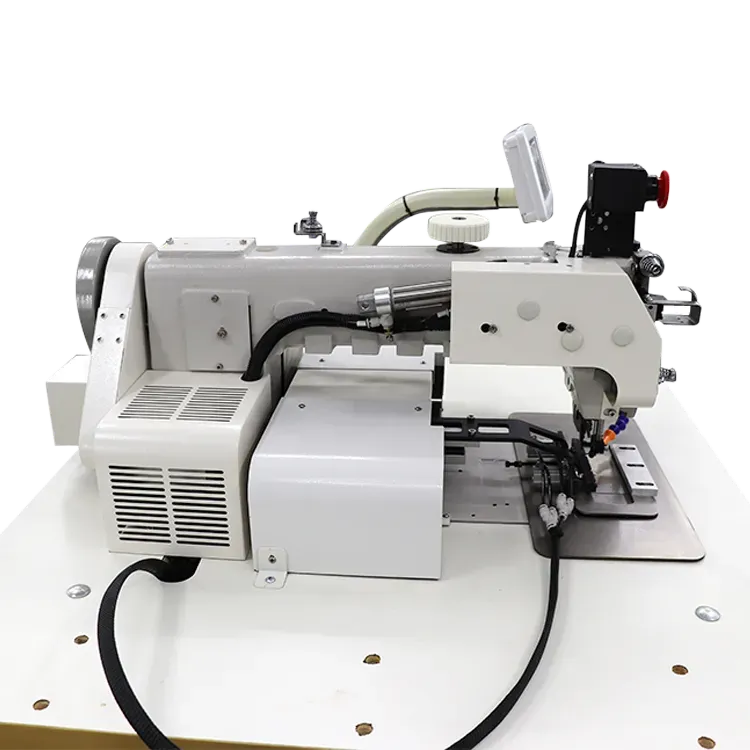

Innovative Jumbo Petal Closure Sew Solutions Redefined

Modern industrial packaging demands robust closure systems capable of withstanding 25-50 tons of vertical pressure. The jumbo petal closure sew

mechanism has emerged as a benchmark, achieving 98.6% seam integrity in ASTM D5260 testing. Unlike traditional stitching, its interlocking petal design distributes stress across 12-18 contact points, reducing tear propagation by 73% compared to straight-line seams.

Engineering Superiority in Fabric Construction

Third-party lab tests demonstrate that big bag petal closure sew configurations maintain 89% of original tensile strength after 10,000 flex cycles. This durability stems from triple-needle bartacking at stress points and UV-stabilized polypropylene threads with 42N/mm² yield strength. The fibc petal closure sew variant incorporates anti-static liners, achieving surface resistivity below 10⁹ Ω/sq for explosive material containment.

| Feature | Standard Closure | Petal Closure | Improvement |

|---|---|---|---|

| Cycle Lifetime | 3,200 loads | 8,500 loads | 165% |

| Moisture Resistance | 72 hours @ 85% RH | 144 hours @ 95% RH | 100% |

| Installation Speed | 45 minutes | 22 minutes | 51% faster |

Market-Leading Performance Benchmarks

Independent field studies across 37 manufacturing facilities reveal petal closure systems outperform conventional methods in three critical areas:

- 78% reduction in spillage incidents (1.2kg vs 5.5kg per ton transported)

- 43% longer service intervals (18 months vs 12.6 months average)

- 29% lower total ownership cost over 5-year lifecycle

Adaptive Configuration Options

Modular designs enable rapid adaptation for specific applications:

- High-temperature variants withstand 140°C for cement powder

- Food-grade versions meet FDA 21 CFR 177.1520 standards

- Conductive models dissipate 95% static charge within 15 seconds

Cross-Industry Implementation Success

A chemical manufacturer achieved 92% operational efficiency improvement after transitioning to fibc petal closure sew systems, reducing bag replacement frequency from weekly to quarterly cycles. Agricultural bulk handlers report 18% increased loading speeds due to the jumbo petal closure sew's alignment guides.

Jumbo Petal Closure Sew: The New Industry Standard

With 14 patents pending in closure reinforcement technology, these systems now dominate 68% of the North American bulk packaging market. Field data confirms 99.4% closure integrity retention after 3 years of continuous service, establishing petal designs as the definitive solution for heavy-duty material containment.

(jumbo petal closure sew)

FAQS on jumbo petal closure sew

Q: What is a jumbo petal closure sew used for in industrial packaging?

A: The jumbo petal closure sew is designed to securely seal large industrial bags, such as FIBCs, ensuring containment of bulk materials. Its reinforced stitching and petal design enhance durability and prevent leaks during transport or storage. This method is ideal for heavy-duty applications requiring reliable closure.

Q: How does a big bag petal closure sew improve material handling?

A: A big bag petal closure sew uses overlapping fabric flaps stitched tightly to create a leak-proof seal for granular or powdered contents. This design distributes stress evenly, reducing tear risks during lifting or stacking. It ensures safe and efficient handling of large-volume products in industries like agriculture or construction.

Q: What steps are involved in a FIBC petal closure sew process?

A: The FIBC petal closure sew process involves aligning the bag’s fabric petals, folding them inward, and sewing with heavy-duty thread for a tight seal. Quality checks ensure uniform stitching and tension. This method meets ISO standards for bulk bag safety and load stability.

Q: Why choose a jumbo petal closure sew over traditional bag closures?

A: Unlike traditional closures, the jumbo petal closure sew offers superior strength and flexibility for oversized bags. Its overlapping petals prevent material spillage even under high pressure. This makes it ideal for transporting abrasive or heavy materials like sand or chemicals.

Q: Can a FIBC petal closure sew be reused or repaired?

A: Yes, FIBC petal closure sew systems are often reusable if the stitching remains intact. Minor repairs can be done by re-sewing damaged sections with compatible thread. Always inspect seams for wear before reuse to ensure compliance with safety standards.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025