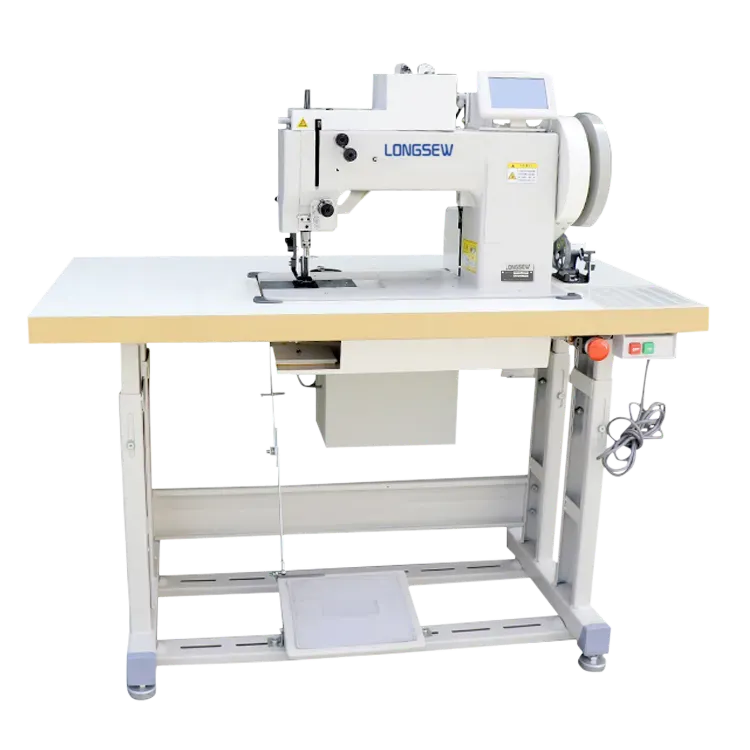

industrial sewing machine for auto upholstery

Industrial Sewing Machines for Auto Upholstery A Comprehensive Overview

In the world of automobile manufacturing and custom car interiors, industrial sewing machines play a pivotal role, especially when it comes to auto upholstery. These specialized machines are designed to handle the unique requirements of upholstery work, which includes sewing thicker materials, multiple layers, and creating intricate designs that enhance the aesthetic appeal of vehicles.

Importance of Industrial Sewing Machines

Industrial sewing machines are engineered for durability and efficiency. They are built to operate continuously and can withstand heavy usage. This is particularly important in auto upholstery, where precision and speed are essential. The demand for high-quality upholstery in automobiles has led to the development of machines that cater specifically to the industry’s needs.

These machines come equipped with features tailored for upholstery tasks. For instance, heavy-duty walking foot mechanisms allow the machine to feed multiple layers of fabric smoothly, ensuring even stitching without skipping. This is crucial when working with materials like leather, vinyl, or heavy fabrics commonly used in car interiors.

Features to Consider

When selecting an industrial sewing machine for auto upholstery, there are several features to consider

1. Stitching Capacity Look for machines that can accommodate a variety of stitch types, including straight, zig-zag, and decorative stitches. These capabilities are important for creating unique designs and patterns on upholstery.

industrial sewing machine for auto upholstery

2. Feed Mechanism A walking foot feeding system is essential for working with thick materials, as it ensures that all layers are fed evenly through the machine.

3. Motor Strength Machines with powerful motors are ideal for auto upholstery, as they can handle thicker threads and tougher materials with ease.

4. Adjustable Presser Foot Adjustable presser feet allow for better control when sewing different thicknesses of fabric, ensuring consistent pressure and preventing fabric slippage.

5. Specialized Feet Attachments Various specialized feet attachments can be used for different tasks, such as piping, quilting, or hemming, making the sewing process more versatile.

Economic Impact

Investing in a good quality industrial sewing machine for auto upholstery can have significant economic benefits for businesses. By reducing the time it takes to produce high-quality upholstery, companies can increase their output and revenue. Furthermore, having the ability to produce custom designs can attract a wider customer base, enhancing brand reputation and fostering customer loyalty.

Conclusion

In conclusion, industrial sewing machines are indispensable in the realm of auto upholstery. Their specialized features and robust design cater to the challenges faced by upholstery professionals. As the automotive industry continues to evolve, the demand for high-quality, aesthetically pleasing interiors will persist, making these machines a valuable asset in any upholstery workshop. Investing in the right industrial sewing machine not only boosts productivity but also elevates the standard of craftsmanship in the automotive upholstery sector. For businesses looking to thrive in this competitive market, having the right tools is no longer a luxury but a necessity.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025