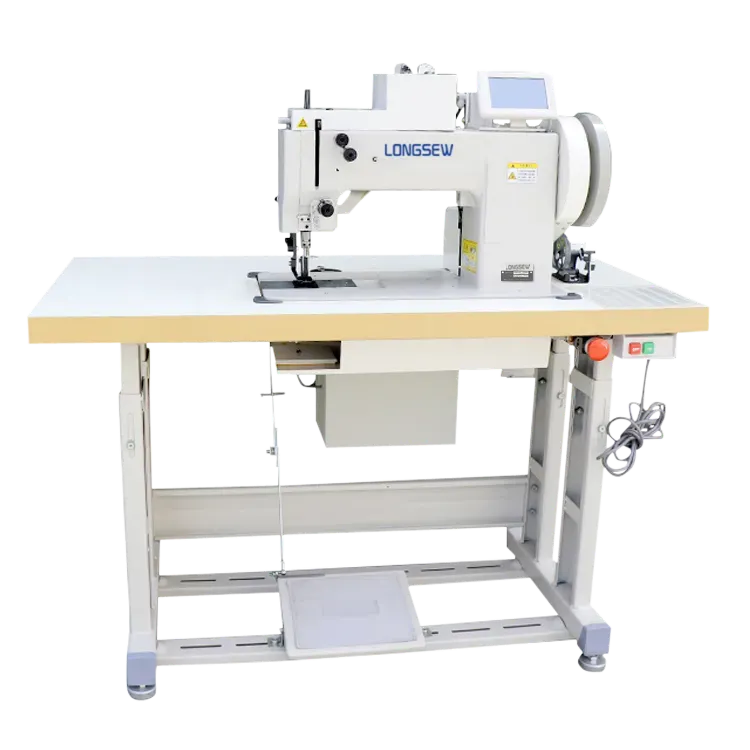

industrial chain stitch machine

Understanding the Industrial Chain Stitch Machine

In the realm of textile manufacturing, the industrial chain stitch machine stands out as a vital tool that facilitates efficient and high-quality sewing operations. This article aims to explore the intricacies of chain stitch machines, their applications in various industries, and their impact on textile production.

What is a Chain Stitch Machine?

A chain stitch machine is a type of sewing machine that forms a stitch using a single thread and a needle, with the stitch being reinforced by looping the thread around the fabric. The key characteristic of this machine is that it produces a chain-like stitch rather than the traditional lock stitch seen in most home sewing machines. This is achieved through the use of a looper mechanism, which creates a series of interlocking loops on the underside of the fabric.

How Does it Work?

The operation of a chain stitch machine involves several crucial components. The primary components include the needle, looper, feed dogs, and tension discs. The needle pierces the fabric and draws the upper thread down, while the looper catches this thread and pulls it through itself, creating a series of loops. This process produces a stitch that is both durable and flexible, making it ideal for various types of fabric and sewing tasks.

One of the unique features of chain stitch machines is their ability to sew at high speeds, significantly increasing productivity in manufacturing settings. Depending on the model and application, these machines can achieve speeds of up to 5000 stitches per minute.

Applications of Chain Stitch Machines

Chain stitch machines are predominantly used in the garment and textile industries. They are essential in sewing lightweight fabrics, particularly in the production of garments such as T-shirts, blouses, and lingerie. The flexibility and stretchability of chain stitches make them suitable for seams that undergo tension, allowing the fabric to maintain its shape and integrity.

industrial chain stitch machine

Beyond garment manufacturing, chain stitch machines also find applications in the production of home textiles, such as curtains and bed linens. Additionally, they play a crucial role in the automotive and upholstery industries, where they are used to sew seat covers and other fabric components that require durability and strength.

Advantages of Using Chain Stitch Machines

One of the foremost advantages of chain stitch machines is their speed. In a fast-paced production environment, the ability to sew quickly and efficiently can lead to increased output and reduced labor costs. Furthermore, chain stitches are less likely to unravel compared to their lock-stitch counterparts, which can lead to decreased fabric waste and lower production costs.

Additionally, the versatility of chain stitch machines allows them to handle a wide range of fabrics, from lightweight to medium-weight materials. This adaptability makes them an invaluable asset for manufacturers who work with different types of textiles or frequently change their production lines.

Challenges and Considerations

Despite their numerous advantages, there are challenges associated with chain stitch machines. One primary concern is the necessity for proper thread tension. If the tension is too loose, the stitches may become loose and result in an uneven seam. Conversely, excessive tension can lead to thread breakage and fabric damage. Therefore, regular maintenance and precise adjustments are essential for optimal performance.

Another challenge is the limited ability of chain stitches to secure fabric edges. While chain stitch machines are excellent for creating seams, they may require additional overlock or finishing techniques to prevent fraying and unraveling of edges.

Conclusion

The industrial chain stitch machine is a cornerstone of modern textile manufacturing, showcasing a perfect blend of speed, efficiency, and versatility. As the apparel and textile industries continue to evolve, the demand for these machines is likely to grow, emphasizing their importance in the production chain. As manufacturers seek innovative solutions to enhance productivity and meet consumer demands, chain stitch machines will undoubtedly remain a crucial player in the ever-changing landscape of fabric production.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025