студ . 29, 2025 03:17

Back to list

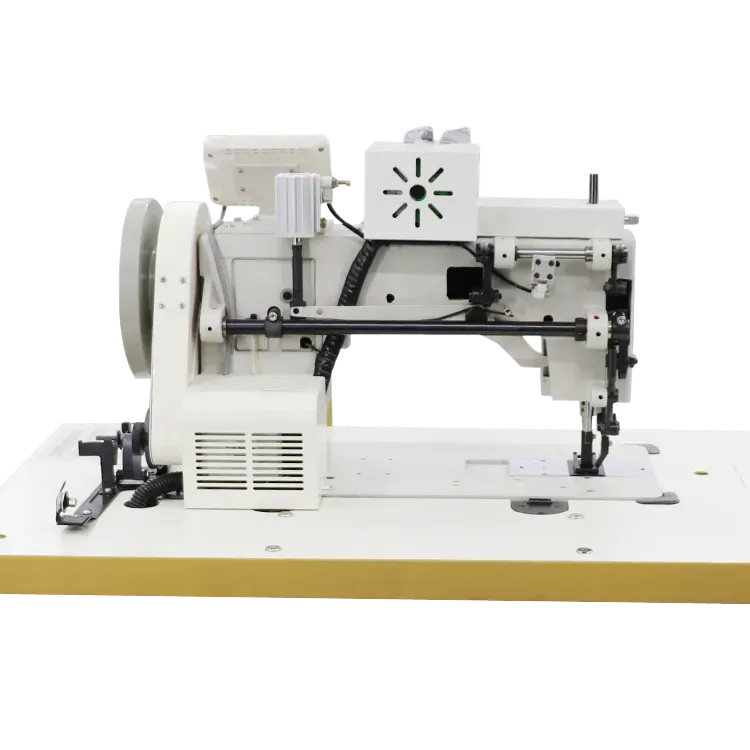

heavy duty industrial sewing machines for sale

Finding the perfect heavy-duty industrial sewing machine can significantly enhance production efficiency and product quality. When balancing factors such as durability, speed, and budget, the process can become overwhelming. This guide aims to clarify these factors and help businesses make informed decisions about purchasing these essential tools.

The investment in an industrial sewing machine should also consider energy efficiency. Many modern machines are designed to consume less power, which not only lowers overhead costs but also aligns with environmentally-conscious business practices. Choosing a machine with a high energy efficiency rating contributes to sustainable business models and reduces the ecological footprint. While the initial cost of these machines might be higher than domestic models, their long-term benefits and return on investment usually justify the expense. Durable construction reduces maintenance costs, and their efficiency boosts production output, ultimately increasing profit margins. When considering a purchase, businesses should evaluate their specific needs carefully. For example, a company specializing in leather goods might prefer a machine with a walking foot mechanism, which helps in dealing with thick and layered materials better than a standard presser foot. Similarly, a manufacturer focusing on sportswear may prioritize machines that offer advanced zigzag stitch capabilities. Market research is equally important in making an informed decision. Various online platforms and trade shows provide information and demos of different models, allowing potential buyers to compare features and prices. Customer reviews and testimonials also offer insights into a machine's real-world performance and reliability. In conclusion, investing in heavy-duty industrial sewing machines is a strategic move for any business involved in garment production or fabric-related ventures. These machines are not only about speed and strength but are also pivotal in producing quality products efficiently. By considering factors such as durability, support, energy efficiency, and specific operational needs, businesses can select machines that align perfectly with their goals. As a trusted tool in many industries, the right machine can elevate a company’s production capabilities, ensuring long-term success and customer satisfaction.

The investment in an industrial sewing machine should also consider energy efficiency. Many modern machines are designed to consume less power, which not only lowers overhead costs but also aligns with environmentally-conscious business practices. Choosing a machine with a high energy efficiency rating contributes to sustainable business models and reduces the ecological footprint. While the initial cost of these machines might be higher than domestic models, their long-term benefits and return on investment usually justify the expense. Durable construction reduces maintenance costs, and their efficiency boosts production output, ultimately increasing profit margins. When considering a purchase, businesses should evaluate their specific needs carefully. For example, a company specializing in leather goods might prefer a machine with a walking foot mechanism, which helps in dealing with thick and layered materials better than a standard presser foot. Similarly, a manufacturer focusing on sportswear may prioritize machines that offer advanced zigzag stitch capabilities. Market research is equally important in making an informed decision. Various online platforms and trade shows provide information and demos of different models, allowing potential buyers to compare features and prices. Customer reviews and testimonials also offer insights into a machine's real-world performance and reliability. In conclusion, investing in heavy-duty industrial sewing machines is a strategic move for any business involved in garment production or fabric-related ventures. These machines are not only about speed and strength but are also pivotal in producing quality products efficiently. By considering factors such as durability, support, energy efficiency, and specific operational needs, businesses can select machines that align perfectly with their goals. As a trusted tool in many industries, the right machine can elevate a company’s production capabilities, ensuring long-term success and customer satisfaction.

Previous:

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025