студ . 14, 2025 09:59

Back to list

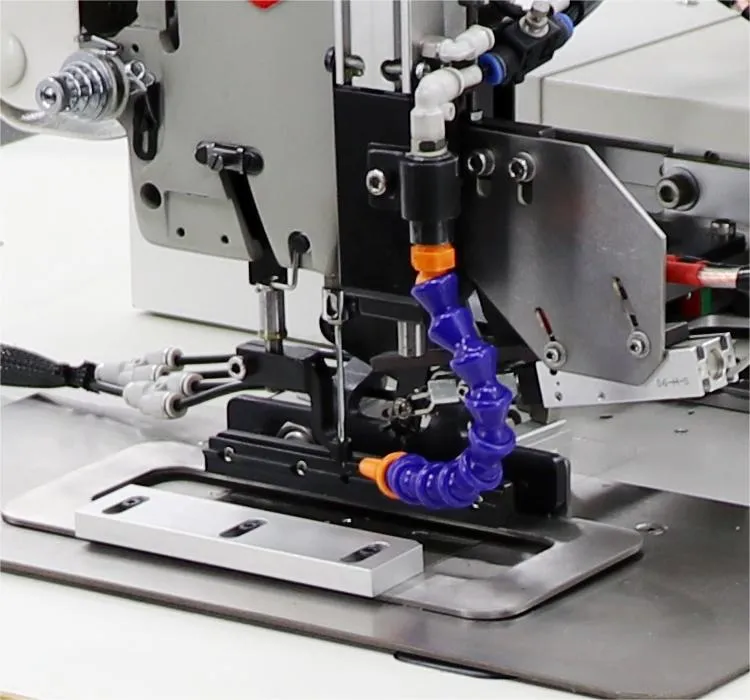

double needle stitching machine

Double needle stitching machines are a cornerstone in the world of garment and upholstery manufacturing, offering unparalleled efficiency and precision for high-volume production. As someone with extensive experience in textile production and machine technology, I have seen firsthand the transformative impact these machines have on modern manufacturing processes.

Authoritativeness in the field of textile machinery is often demonstrated through brand reliability and machine durability. Leading manufacturers such as Brother, JUKI, and Consew are renowned for producing robust machines that withstand the rigors of heavy-duty use. Their commitment to quality and innovation cements their status as authorities in the clothing and textile industries. Investing in machines from these reputable brands ensures longevity and consistent performance, which is crucial for maintaining a competitive edge in the marketplace. Trustworthiness, from a consumer's perspective, involves not only the machine's performance but also the support and warranties provided by manufacturers. Comprehensive after-sales services, including user training and maintenance, are vital. They provide an added layer of security, assuring users that they can rely on both the machine and the manufacturer. When investing in a double needle stitching machine, it's crucial to consider these factors, ensuring that your choice aligns with both current and future production needs. In conclusion, the integration of double needle stitching machines into manufacturing processes represents a confluence of experience, expertise, authoritativeness, and trustworthiness. These machines not only enhance efficiency and precision but also embody the technical prowess and reliability that the modern manufacturing landscape demands. As the textile industry continues to evolve, embracing advanced machinery like double needle stitching machines becomes not only a strategic choice but a necessity for those aspiring to lead in quality and productivity.

Authoritativeness in the field of textile machinery is often demonstrated through brand reliability and machine durability. Leading manufacturers such as Brother, JUKI, and Consew are renowned for producing robust machines that withstand the rigors of heavy-duty use. Their commitment to quality and innovation cements their status as authorities in the clothing and textile industries. Investing in machines from these reputable brands ensures longevity and consistent performance, which is crucial for maintaining a competitive edge in the marketplace. Trustworthiness, from a consumer's perspective, involves not only the machine's performance but also the support and warranties provided by manufacturers. Comprehensive after-sales services, including user training and maintenance, are vital. They provide an added layer of security, assuring users that they can rely on both the machine and the manufacturer. When investing in a double needle stitching machine, it's crucial to consider these factors, ensuring that your choice aligns with both current and future production needs. In conclusion, the integration of double needle stitching machines into manufacturing processes represents a confluence of experience, expertise, authoritativeness, and trustworthiness. These machines not only enhance efficiency and precision but also embody the technical prowess and reliability that the modern manufacturing landscape demands. As the textile industry continues to evolve, embracing advanced machinery like double needle stitching machines becomes not only a strategic choice but a necessity for those aspiring to lead in quality and productivity.

Previous:

Next:

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025