лют . 10, 2025 10:32

Back to list

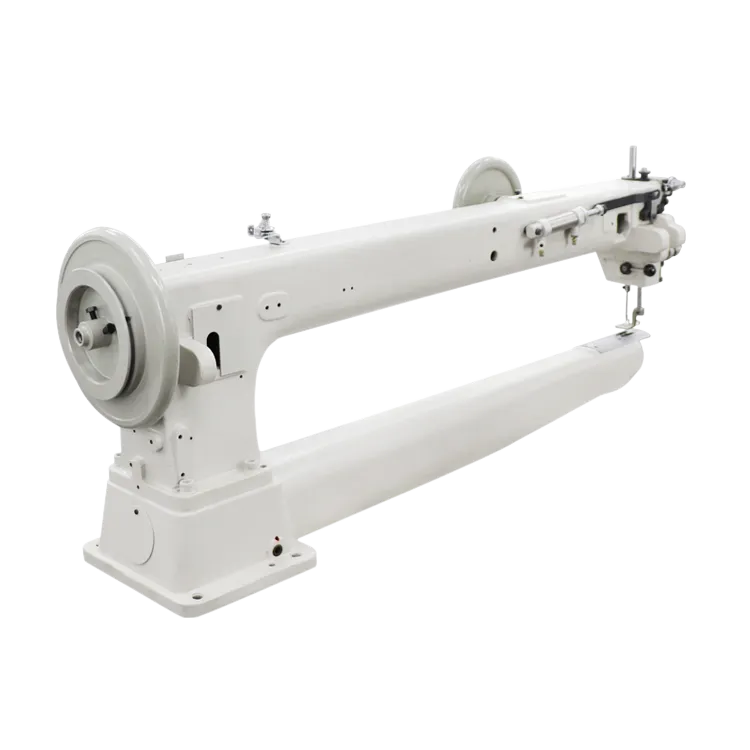

FIBC Bag / Jumbo Bag / Big Bag Double Needles Chain Stitch Sewing Machine 80700C/ 80700CD / 80700CD4H

Cylindrical sewing machines have emerged as indispensable tools in the textile and leather industries, where precision and efficiency are paramount. Unlike traditional flatbed machines, these machines offer a distinctive advantage due to their unique tubular design, allowing for easy manipulation of cylindrical or tubular items such as sleeves, trouser legs, and bags. This article delves into the practical advantages of cylindrical sewing machines, shedding light on their capability to revolutionize production processes.

Moreover, expertise in operating cylindrical sewing machines provides users with a competitive edge within the industry. Operators skilled in managing these machines are highly sought after, as they possess the ability to maximize the machine’s capabilities. Experienced operators understand the nuanced adjustments required for different fabrics and designs, thereby enhancing the machine's output quality. Training programs and certifications by experienced professionals further contribute to elevating the operator's proficiency, ensuring that the machine is utilized to its full potential. Trustworthiness is cemented by the long-standing performance and durability of cylindrical sewing machines. Constructed with robust materials and advanced engineering, these machines are built to withstand the rigors of continuous industrial use. Manufacturers often offer extended warranties and after-sales service, reinforcing customer confidence and ensuring long-term reliability. This commitment to quality and support underscores their position as a reliable choice for businesses aiming to invest in long-lasting sewing solutions. In terms of innovation, manufacturers continuously evolve cylindrical sewing machines by integrating cutting-edge technology. Modern machines are equipped with computerized systems that allow for precise control of stitch patterns and speeds, enhancing productivity. Bluetooth and IoT integration enable seamless data tracking and machine diagnostics, minimizing downtime and maintenance issues. This technological uplift further solidifies the machine's authoritative role in the industry, ensuring it remains relevant in a fast-evolving market landscape. In conclusion, cylindrical sewing machines represent a fusion of innovation, reliability, and expertise. Their tailored design for specialized sewing tasks makes them a crucial asset in the production of high-quality textile and leather products. By embracing technological advancements and adhering to rigorous quality standards, these machines continue to uphold their reputation as indispensable tools for modern-day garment and accessory manufacturing. As the industry progresses, the role of cylindrical sewing machines will only expand, driven by continuous innovation and the ever-growing demand for precision in manufacturing processes.

Moreover, expertise in operating cylindrical sewing machines provides users with a competitive edge within the industry. Operators skilled in managing these machines are highly sought after, as they possess the ability to maximize the machine’s capabilities. Experienced operators understand the nuanced adjustments required for different fabrics and designs, thereby enhancing the machine's output quality. Training programs and certifications by experienced professionals further contribute to elevating the operator's proficiency, ensuring that the machine is utilized to its full potential. Trustworthiness is cemented by the long-standing performance and durability of cylindrical sewing machines. Constructed with robust materials and advanced engineering, these machines are built to withstand the rigors of continuous industrial use. Manufacturers often offer extended warranties and after-sales service, reinforcing customer confidence and ensuring long-term reliability. This commitment to quality and support underscores their position as a reliable choice for businesses aiming to invest in long-lasting sewing solutions. In terms of innovation, manufacturers continuously evolve cylindrical sewing machines by integrating cutting-edge technology. Modern machines are equipped with computerized systems that allow for precise control of stitch patterns and speeds, enhancing productivity. Bluetooth and IoT integration enable seamless data tracking and machine diagnostics, minimizing downtime and maintenance issues. This technological uplift further solidifies the machine's authoritative role in the industry, ensuring it remains relevant in a fast-evolving market landscape. In conclusion, cylindrical sewing machines represent a fusion of innovation, reliability, and expertise. Their tailored design for specialized sewing tasks makes them a crucial asset in the production of high-quality textile and leather products. By embracing technological advancements and adhering to rigorous quality standards, these machines continue to uphold their reputation as indispensable tools for modern-day garment and accessory manufacturing. As the industry progresses, the role of cylindrical sewing machines will only expand, driven by continuous innovation and the ever-growing demand for precision in manufacturing processes.

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025