cylinder bed sewing machine used

The Advantages of Using Cylinder Bed Sewing Machines

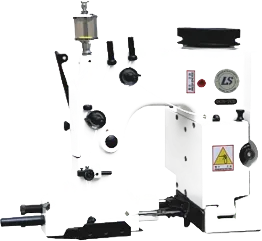

Cylinder bed sewing machines are a specialized type of sewing equipment designed for sewing tubular or cylindrical fabrics, making them an invaluable tool in various industries, particularly in garment manufacturing. Their unique structure, featuring a cylindrical arm, allows for easy access and manipulation of curved and tubular items, such as sleeves, cuffs, collars, and other intricate designs.

The Advantages of Using Cylinder Bed Sewing Machines

Additionally, cylinder bed sewing machines are highly versatile. They can be equipped with various attachments and sewing feet, allowing for different types of stitching. This adaptability makes them suitable for a wide range of materials, including stretch fabrics, leather, and heavy-duty textiles. As a result, factories can utilize cylinder bed machines for multiple projects, reducing the need for various types of sewing machines in their production lines.

cylinder bed sewing machine used

Moreover, the ergonomic design of cylinder bed sewing machines helps reduce operator fatigue during long hours of sewing. Since the operator can easily navigate around the fabric and maintain a comfortable posture, this leads to improved productivity and a lower risk of workplace injuries, which is a crucial factor for garment manufacturers aiming to maintain a healthy workforce.

In terms of investment, while cylinder bed sewing machines might come at a higher initial cost than traditional sewing machines, their efficiency and ability to produce high-quality products can lead to a significant return on investment over time. As businesses grow and evolve, having the right tools to meet production demands becomes vital, and cylinder bed sewing machines are certainly worth considering.

In conclusion, cylinder bed sewing machines bring a multitude of benefits to the sewing industry. Their ability to easily navigate tubular fabrics, versatility, ergonomic design, and potential for high-quality output make them an excellent choice for manufacturers looking to enhance their production capabilities. Investing in this specialized equipment can ultimately lead to better efficiency and improved product offerings in an increasingly competitive market.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025