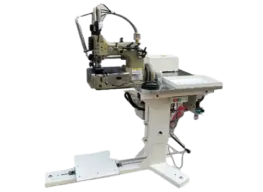

compound sewing machine

The Versatility and Efficiency of Compound Sewing Machines

In the realm of textile production, the compound sewing machine stands out as a critical innovation that has significantly enhanced the sewing process. This type of sewing machine combines multiple sewing functions and features into a single unit, making it a valuable asset for both industrial and home sewing applications.

One of the most notable characteristics of compound sewing machines is their capacity to perform various stitches and techniques. This versatility is largely attributed to their dual feed system, which often includes a walking foot mechanism alongside the traditional presser foot. The walking foot ensures that multiple layers of fabric are fed evenly through the machine, which is essential for projects such as quilting, bag making, and other heavy-duty sewing tasks. This ability to manage different fabric thicknesses means that users can tackle a wide range of materials, from lightweight fabrics like chiffon to heavier materials like canvas and denim.

Moreover, compound sewing machines are designed for efficiency. Their construction often includes an automatic needle positioner and programmable features that allow for precise stitching and repetition. This automation reduces the time spent on manual adjustments, thus boosting productivity, particularly in commercial settings where high-volume output is required. The time saved can be reinvested in other tasks, improving overall workflow and project turnaround times.

compound sewing machine

In addition to their practical applications, compound sewing machines also herald a new era in creative possibilities. Sewists can explore intricate designs and embellishments that might be challenging to execute with a standard machine. Features such as built-in embroidery options and programmable stitch patterns allow for greater creativity, enabling crafters and designers to push the boundaries of their projects. Whether creating custom apparel, crafting home décor items, or designing unique accessories, the compound sewing machine proves essential in turning imaginative ideas into reality.

Maintenance and durability are other key considerations for users of compound sewing machines. Designed to withstand heavy use, these machines typically come with robust components and require relatively low maintenance. Regular oiling and proper care will ensure longevity, making them a worthwhile investment for both hobbyists and professionals.

Another advantage of compound sewing machines is their adaptability. Many models come equipped with interchangeable feet and attachments, catering to various sewing techniques and styles. This adaptability allows users to modify their machines according to specific project needs, further enhancing their versatility. For instance, installing a walking foot attachment can provide additional support for slippery materials, ensuring a smooth sewing experience.

In summary, compound sewing machines represent a blend of versatility, efficiency, and creativity that can dramatically transform the sewing experience. Their ability to handle multiple fabric types, automate tasks, and facilitate intricate designs makes them invaluable to both industrial users and sewing enthusiasts. As technology continues to advance, the potential for compound sewing machines will only expand, offering a promising future for the textile industry and its creators. Whether you are a seasoned professional or a novice sewer, investing in a compound sewing machine could be your gateway to endless sewing possibilities, elevating your projects to new heights of quality and craftsmanship.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025