chain stitch machine

Understanding the Chain Stitch Machine An Essential Tool in Textile Manufacturing

In the world of textile manufacturing, precision and efficiency are paramount. Among the various stitching techniques employed in the industry, the chain stitch holds a prominent place, largely attributed to its versatility and strength. At the heart of this technique lies the chain stitch machine, an indispensable tool that has revolutionized sewing and garment production.

The chain stitch itself is characterized by its unique looping mechanism, which creates a series of interlocking stitches without the need for a bobbin thread. This method provides several advantages, particularly in terms of durability and flexibility. Chain stitches are less likely to break under tension, making them ideal for seams that experience significant stress, such as those found in sportswear, workwear, and denim garments. Additionally, the inherent elasticity of the chain stitch allows for better movement, which is crucial for clothing that must accommodate physical activity.

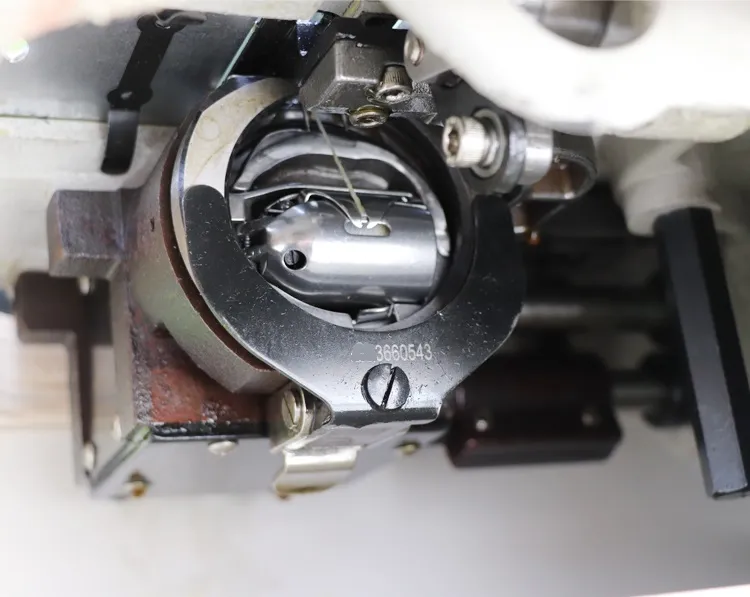

Chain stitch machines operate using a single thread that is fed through a needle, while a looper mechanism catches and loops the thread, forming a continuous chain. This design not only reduces production time but also simplifies the process of threading the machine, as there is no complicated bobbin assembly to manage. Modern chain stitch machines have evolved significantly, with many models featuring automatic functions, adjustable stitch lengths, and even computerized settings that enhance precision and efficiency in garment production.

chain stitch machine

One of the key benefits of the chain stitch machine is its versatility. It can be used for a variety of applications, from basic seams to decorative stitching. In the fashion industry, designers often leverage chain stitches to create unique design elements on garments, such as adding texture or visual interest to hems and seams. This ability to combine functionality with aesthetic appeal makes the chain stitch machine a favorite among manufacturers and designers alike.

Furthermore, the chain stitch machine is also environmentally friendly compared to some other stitching methods. Since chain stitches require less thread to create a secure seam, manufacturers can reduce their material consumption, leading to less waste. This characteristic aligns with the increasing emphasis on sustainability within the textile industry, urging companies to adopt more eco-friendly practices.

However, like any tool, the chain stitch machine is not without its challenges. One drawback is the susceptibility of chain stitches to unraveling if the thread is cut or frayed. This means that extra care must be taken when handling and maintaining garments made with chain stitching. Additionally, while the machine is versatile, it may not be suitable for all types of fabrics or stitches, leading manufacturers to balance their use with other sewing technologies.

In summary, the chain stitch machine is a vital component of the textile manufacturing landscape. Its efficient operation and strong, flexible stitches make it ideal for a wide range of applications, particularly in sectors requiring durability and movement. As the industry continues to prioritize sustainability and innovation, the chain stitch machine stands out as a tool that marries traditional techniques with modern advancements, ensuring its place in the future of garment production. Whether it’s enhancing the durability of clothing or adding decorative details, this machine remains a foundational instrument for any textile manufacturer aiming to meet the demands of today’s market.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025