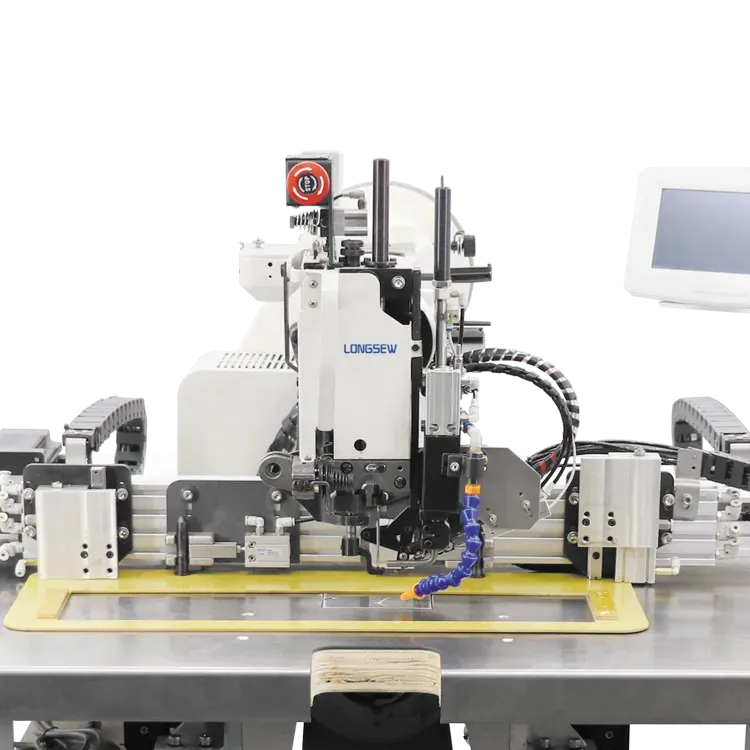

bag closing system

The Bag Closing System An Essential Tool in Packaging Technology

In today's fast-paced industrial landscape, the importance of efficient packaging cannot be overstated. Among the various technologies that facilitate this process, the bag closing system stands out as a vital component in ensuring the integrity and quality of packaged products. This system encompasses a range of technologies and methods designed to securely seal bags, maintaining their contents while providing a professional finish.

Bag closing systems come in various forms, with each type designed to meet specific needs across different industries. The most prevalent methods include heat sealing, sewing, and adhesive sealing. Heat sealing is commonly used for plastic bags and involves the application of heat to bond the edges of the bag together. This method is prevalent in food packaging, where maintaining freshness is paramount. Conversely, sewing is often employed in fabric or paper bags, offering a durable and reliable closure that can withstand significant handling and transport. Adhesive sealing, utilizing specialized adhesives, provides versatility in various packaging applications, allowing for the closure of bags made from different materials.

One of the key advantages of modern bag closing systems is their automation capabilities. Automated bag closing machines have revolutionized the packaging industry by significantly increasing efficiency and throughput. These machines can operate at high speeds, sealing thousands of bags per hour while minimizing labor costs. Additionally, automation reduces the likelihood of human error, ensuring that each bag is sealed consistently and securely.

bag closing system

Moreover, the versatility of bag closing systems allows them to be integrated into existing packaging lines seamlessly. This adaptability is crucial for manufacturers who require customized solutions to meet specific product specifications. The ability to adjust sealing parameters, such as temperature and pressure, further enhances the system's flexibility, accommodating various bag materials and sizes.

In addition to enhancing efficiency and productivity, bag closing systems also play a vital role in product safety and compliance. Properly sealed bags protect contents from contamination, moisture, and external elements, ensuring that products remain safe for consumers. This is particularly important in industries such as food and pharmaceuticals, where regulatory standards necessitate strict adherence to packaging protocols.

Finally, as sustainability becomes a focal point for many industries, bag closing systems are evolving to accommodate eco-friendly materials. Manufacturers are increasingly exploring biodegradable and recyclable materials for bag production, necessitating specialized sealing methods that preserve the integrity of these environmentally sensitive products.

In conclusion, the bag closing system is an indispensable component of packaging technology. Its ability to provide efficient, reliable, and secure closures helps manufacturers meet the demands of modern production while ensuring product safety and sustainability. As the packaging industry continues to evolve, the importance of advanced bag closing technologies will only grow, positioning them at the forefront of packaging innovation.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025