High-Quality Bag Sealing Machines for Efficient Packaging Solutions

The Importance of Bag Sealing Machines in Modern Packaging

In the fast-paced world of manufacturing and packaging, efficiency and quality control play pivotal roles in delivering products to consumers. Among the myriad of equipment available for packaging, bag sealing machines have emerged as indispensable tools that ensure products are securely packaged. This article delves into the significance of bag sealing machines, their types, operational mechanisms, and benefits.

Bag sealing machines are designed to seal plastic or paper bags for a variety of applications, including food packaging, pharmaceuticals, and industrial products. The process not only enhances product freshness but also protects the contents from contamination and tampering. With the growing demand for packaged goods, the need for reliable sealing solutions has become more critical than ever.

There are several types of bag sealing machines available on the market, each tailored for specific requirements. The most common types include heat sealers, impulse sealers, and vacuum sealers. Heat sealers utilize heated elements to melt the edges of the bag, creating a strong seal that can withstand various conditions. Impulse sealers, on the other hand, use electric impulses to generate heat, making them ideal for sealing thicker materials. Vacuum sealers are particularly popular in the food industry, as they remove air from the bag before sealing, thereby extending the shelf life of perishable items.

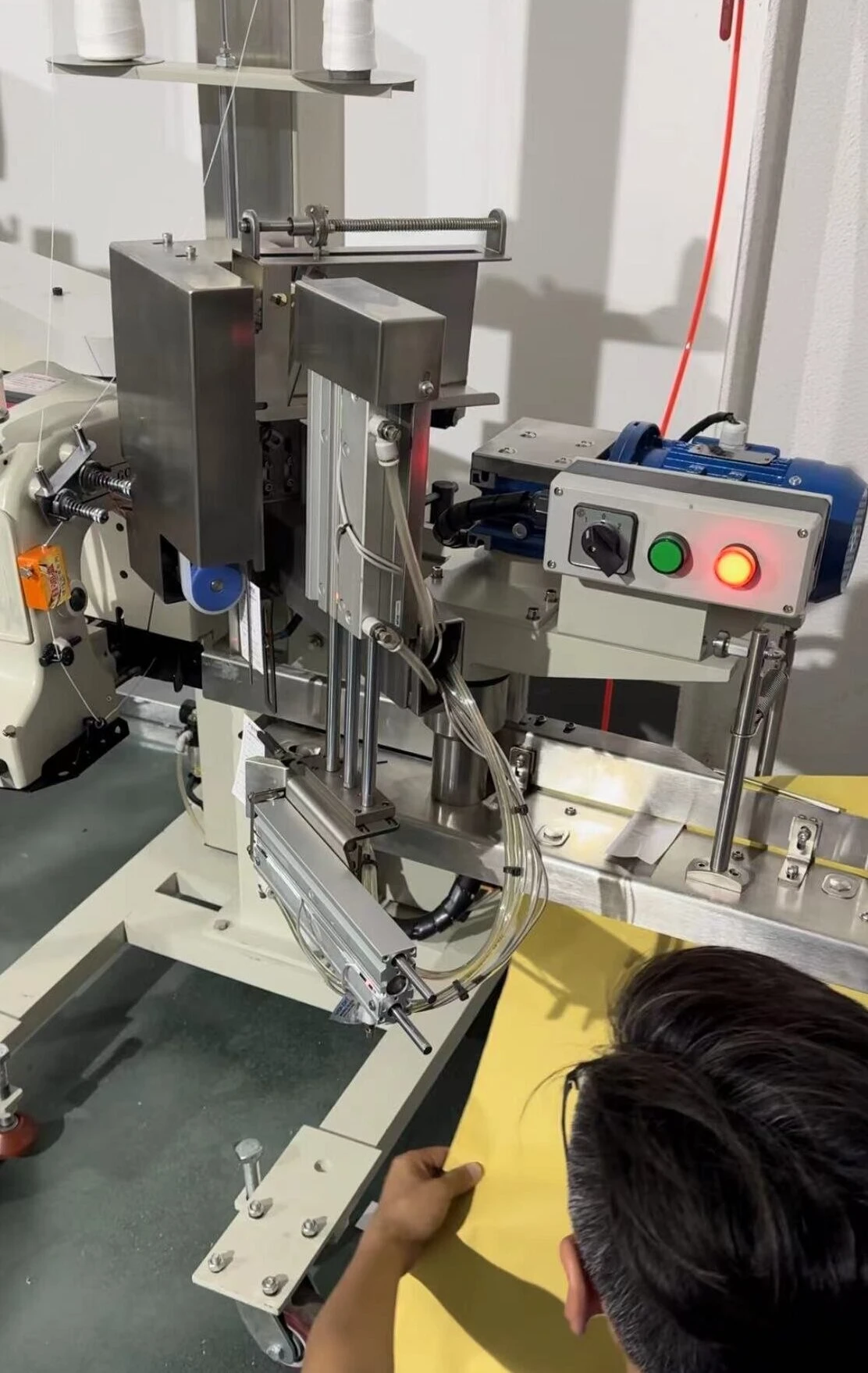

bag sealing machine

The operation of a bag sealing machine is relatively straightforward, making it accessible for small businesses and large manufacturers alike. Typically, the bag is placed in the machine, and the sealing mechanism is activated, either manually or automatically. Depending on the type of machine, this may involve pressing a button, pulling a lever, or activating a pedal. Once the seal is completed, the machine often provides a cutting mechanism to trim any excess bag material, resulting in a professional-looking, neatly sealed product.

The benefits of using bag sealing machines are numerous. Firstly, they significantly enhance productivity. Automated sealing machines can process hundreds of bags per hour, which would be impossible to achieve with manual sealing. Additionally, these machines ensure consistency and quality across all packages, reducing the risk of human error.

Moreover, bag sealing machines contribute to cost savings. By effectively sealing products, they minimize waste and spoilage, particularly in the food industry. This not only leads to reduced costs associated with product loss but also enhances customer satisfaction by delivering fresh and secure products.

In conclusion, bag sealing machines are vital in today’s packaging landscape, offering efficiency, quality, and cost-effectiveness. Whether in a small artisanal business or a large-scale manufacturing facility, these machines provide reliable solutions for businesses eager to meet consumer demands for secure and high-quality packaging. As technology continues to evolve, we can expect further improvements in the capabilities and functionalities of bag sealing machines, making them even more integral to the packaging process.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025