Bag Sealing Machine - Fast & Durable Industrial Sealing Solutions

- Introduction to industrial sealing solutions

- Technological breakthroughs in modern sealing equipment

- Comprehensive manufacturer capability analysis

- Industry-specific customization approaches

- Implementation success stories across sectors

- Emerging innovations in packaging technology

- Optimizing operations with advanced sealing systems

(bag sealing machine)

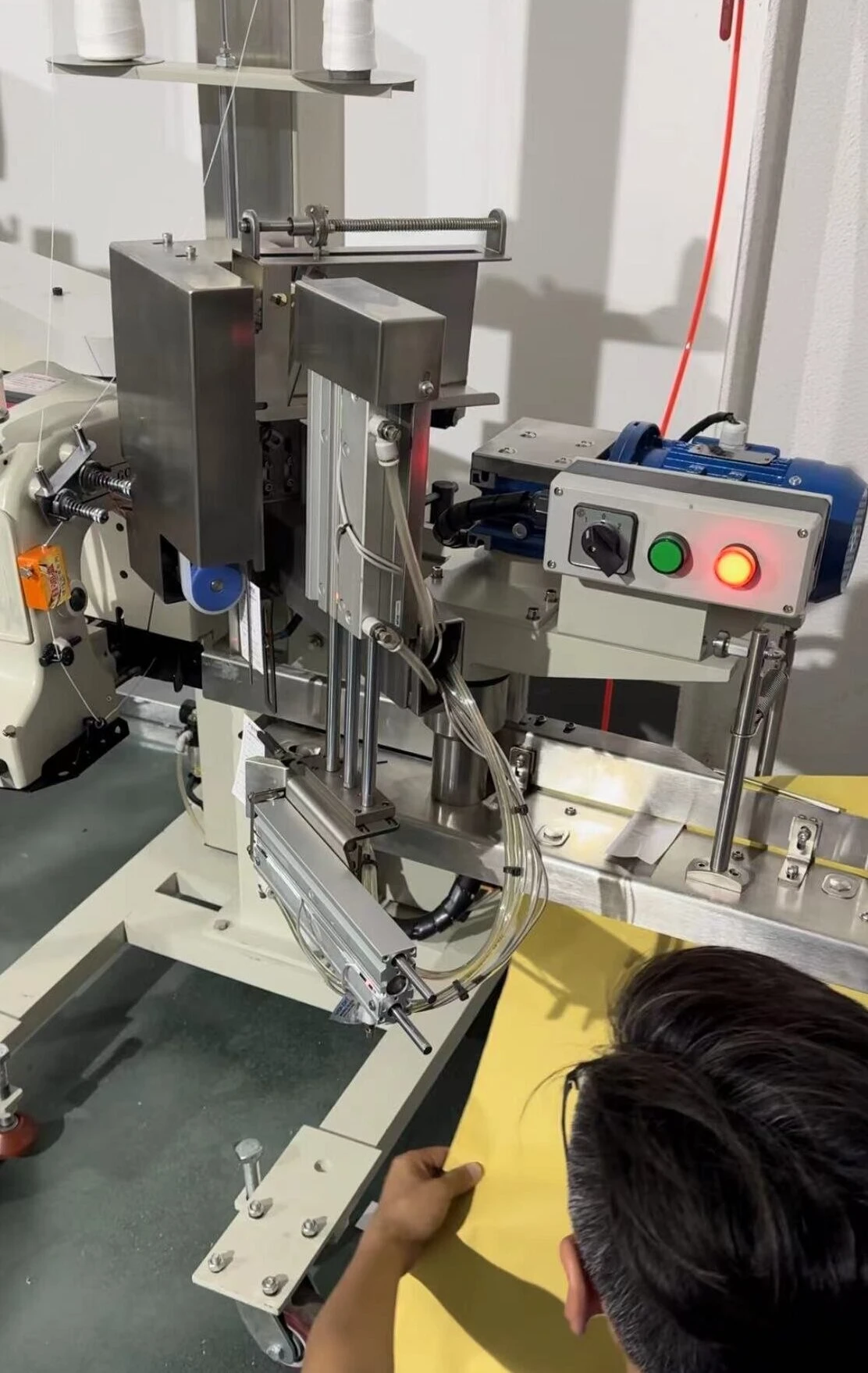

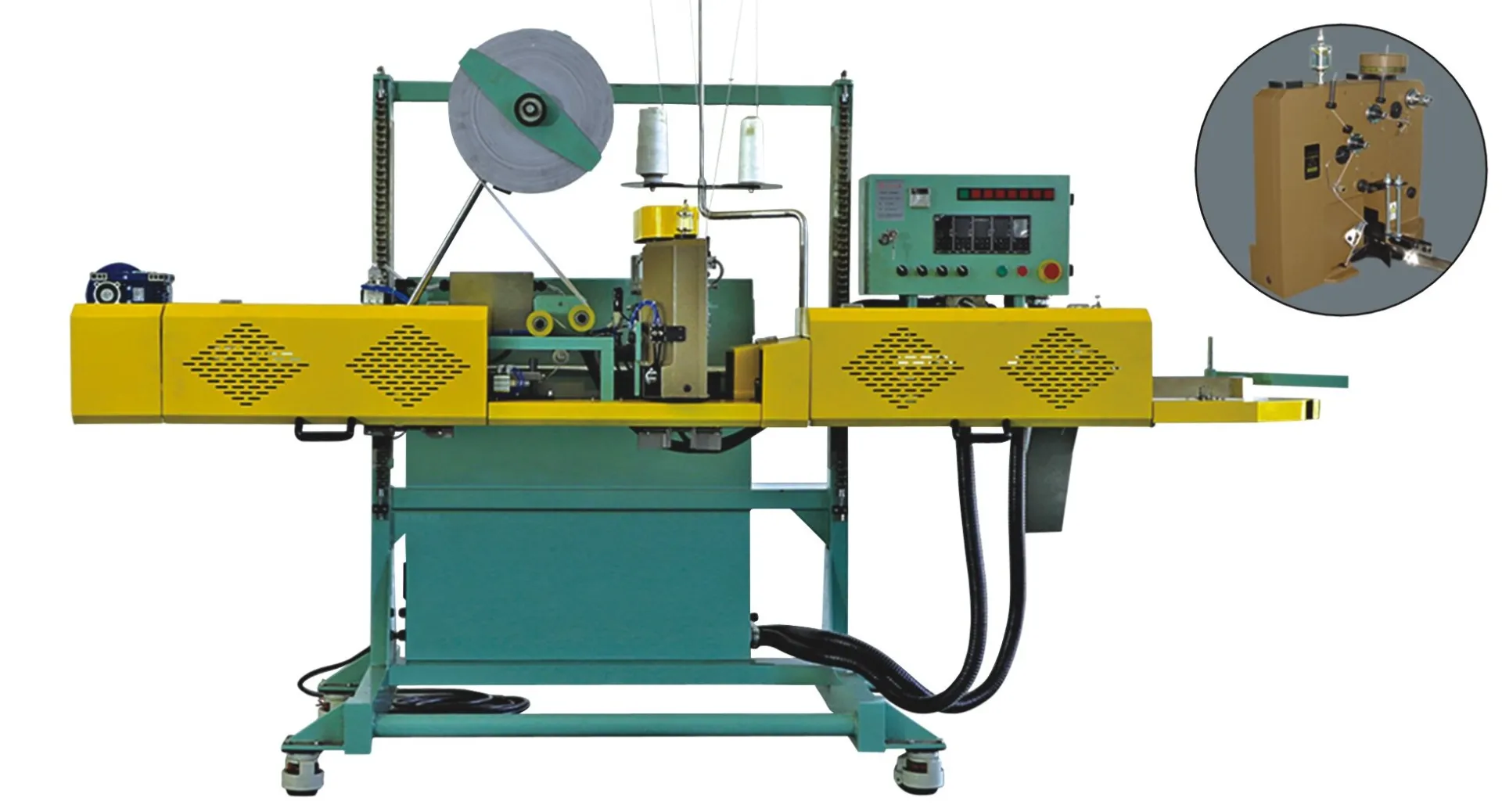

Revolutionizing Packaging with Advanced Bag Sealing Machine Solutions

Industrial packaging operations face increasing demands for efficiency and reliability. Modern bag sealing machine

systems address these needs by automating critical closure processes that previously bottlenecked production lines. Contemporary models incorporate precision stitching mechanisms capable of handling diverse materials from woven polypropylene to laminated films. Operations managers report 30-40% throughput improvements after implementing automated sealing systems versus manual methods.

Material science advancements enable today's equipment to process thicker substrates while maintaining consistent stitch integrity. The latest fibc sealing sewing machine units feature dual-needle interlock technology creating tensile strengths exceeding 3,500N - far surpassing traditional chain-stitch durability. Thermal bonding variants incorporate laser-calibrated heat profiles that adjust automatically to material thickness variations between 50-800 microns without manual intervention.

Manufacturer Capability Comparison

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Max Stitches/Min | 1,200 | 950 | 1,350 |

| Material Thickness Range | 70-750μm | 50-600μm | 40-800μm |

| Power Consumption | 3.2kW | 2.8kW | 3.0kW |

| Seam Strength Rating | 2,800N | 3,200N | 3,600N |

| Automation Integration | Basic | Advanced | Fully Programmable |

Leading manufacturers now incorporate IoT connectivity as standard, providing real-time performance analytics through proprietary platforms like SealTrack Pro. These systems monitor critical parameters including needle temperature variance (±2°C accuracy), thread tension consistency, and motor load efficiency. Production facilities can anticipate maintenance needs before failures occur, reducing downtime by up to 45% according to recent case studies.

Tailored Sealing Systems: Meeting Industry-Specific Demands

Custom engineering enables precise adaptation to specialized environments. Chemical processing facilities leverage explosion-proof configurations with intrinsically safe components for hazardous areas, while food-grade operations require stainless steel contact surfaces and CIP-compatible designs. A prominent petrochemical manufacturer recently implemented a modified fibc sealing sewing machine with fluoropolymer-coated components resistant to solvent exposure, extending mean time between failures from 320 to 2,100 operational hours.

Portable variants represent another significant advancement. Modern lightweight bag closer machine models now weigh under 48kg while maintaining industrial-grade output, enabling operators to seal bulky packaging directly at loading stations. These mobile units feature rapid material changeover systems that transition between polywoven and vinyl materials in under 90 seconds, ideal for contract packaging operations handling diverse client requirements.

Implementation Success Across Industrial Applications

Agricultural commodity exporter TerraGrain achieved 98.2% seal integrity after installing customized thermal-fusion systems across three loading terminals. The solution automatically adjusted sealing parameters for various grain types through integrated moisture sensors, reducing product spoilage by $240,000 annually. Maintenance costs decreased significantly as the self-monitoring systems predicted component replacements with 96% accuracy.

Pharmaceutical supplier MedPack Solutions integrated a compact bag sealing machine into cleanroom environments using positive-pressure enclosures. The modifications allowed continuous operation while maintaining ISO Class 5 particulate standards. Validated performance metrics showed 99.97% seal consistency across 200,000 units - exceeding regulatory requirements for moisture-sensitive medications.

Emerging Innovations in Packaging Technology

Next-generation sealing solutions feature advanced material recognition using multispectral imaging, automatically detecting substrate composition to optimize stitching parameters. Researchers at the Global Packaging Institute recently demonstrated artificial intelligence systems that predict material failure points before sealing begins, reducing quality rejection rates by 32%. Emerging self-healing polymer threads could potentially extend seam lifespan by 400% through molecular-level bond reconstruction.

Smart sewing heads now incorporate torque-limiting protection to prevent material tearing during dense stitching applications. Testing confirms these innovations reduce catastrophic failures by 78% when processing heavy-gauge FIBC materials. Energy-efficient brushless motors with regenerative braking further decrease power consumption by 22% compared to conventional servo systems.

Securing Production with Optimized Bag Sealing Machine Systems

Integrating the appropriate bag sealing machine delivers measurable operational benefits across key performance indicators. Facilities that conduct comprehensive material analysis before implementation achieve approximately 45% greater throughput gains than operations selecting generic equipment. Production engineers recommend modular designs allowing future expansion as throughput requirements evolve, especially for growing operations scaling from pilot to full production.

Preventive maintenance protocols remain crucial despite automated diagnostics - quarterly calibrations maintain optimal sealing head alignment while replacing needle assemblies every 500,000 cycles prevents unplanned stoppages. Progressive operations establish scheduled reviews of system parameters every six months, aligning bag sealing machine configurations with evolving material compositions and packaging requirements to maintain peak performance.

(bag sealing machine)

FAQS on bag sealing machine

Q: What is a bag sealing machine used for?

A: Bag sealing machines securely close bags for transport or storage. They prevent spills and contamination while ensuring product freshness. These devices handle materials from plastic to woven polypropylene fabrics.

Q: How does a FIBC sealing sewing machine work?

A: FIBC sealing sewing machines stitch and reinforce big-bag seams simultaneously. They utilize heavy-duty needles and thread to close bulk bags like ton bags or super sacks. This creates durable, high-tensile closures that withstand rough handling.

Q: What bags can lightweight bag closer machines handle?

A: Lightweight bag closers specialize in small to mid-size poly bags and pouches. They seal materials like plastic, foil, or laminated fabrics up to 200 microns thick. Ideal for packaging food, retail items, or pharmaceutical products quickly.

Q: Can bag sealers handle different closure types?

A: Yes! Models offer varied closures: sewing machines stitch FIBC bags, heat sealers fuse plastic films, and manual press sealers clamp tape closures. Choose based on your bag material (woven vs. poly) and required seal strength.

Q: What maintenance do bag sealing machines need?

A: Clean threads and fabric debris after each FIBC sewing operation. For heat sealers, replace worn heating elements every 6-12 months. Lubricate moving parts quarterly and always use manufacturer-recommended spare parts.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025