Innovative Sewing Technology for Efficient Shoe Manufacturing Solutions

The Evolution and Impact of Automatic Shoe Sewing Machines

In the world of footwear manufacturing, efficiency and precision are paramount. As consumer demand grows and fashion trends shift swiftly, the shoe industry has had to adapt, leading to the rise of automatic shoe sewing machines. These innovative machines revolutionize the production process, enhancing both speed and quality while reducing labor costs and human error.

Automatic shoe sewing machines have come a long way since their inception in the early 19th century. The first sewing machines were mechanical devices that significantly improved the time taken to stitch shoes. However, as technology advanced, so did the sophistication of these machines. Today's automatic sewing machines are equipped with computer-controlled systems, enabling them to perform intricate stitching patterns and adjust themselves to the specifications of various shoe designs.

One of the most notable features of modern automatic shoe sewing machines is their ability to handle multiple materials. Whether it's leather, synthetic fabrics, or textiles, these machines can adapt to different materials without compromising the integrity of the shoe. This versatility not only enhances production capabilities but also allows manufacturers to experiment with innovative designs and materials, meeting consumer trends more effectively.

Moreover, the speed of automatic shoe sewing machines is another significant advantage. These machines can sew at unprecedented speeds, completing tasks that would take manual laborers hours in just a fraction of the time. This increased efficiency allows manufacturers to produce more footwear in less time, ensuring that they meet market demands swiftly. The capacity to scale production efficiently is crucial in an era where fashion trends change rapidly and consumers expect new styles to be available almost immediately.

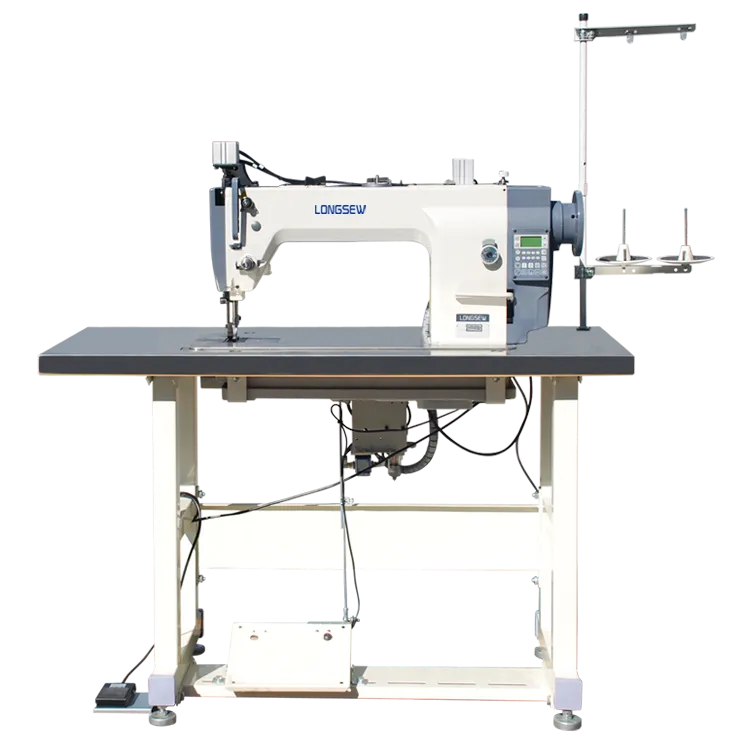

automatic shoe sewing machine

Additionally, automated machines contribute to improved quality control. With built-in sensors and advanced stitching technology, automatic shoe sewing machines can maintain consistent stitch quality throughout the production process. This uniformity reduces the likelihood of defects and ensures that every shoe meets high standards, which is essential for maintaining brand reputation and customer satisfaction.

The impact of automatic shoe sewing machines extends beyond the manufacturing floor. By reducing the need for manual labor in the sewing process, companies can allocate their resources more effectively, focusing on design, marketing, and other critical areas of the business. This shift can lead to innovation in shoe design and help companies remain competitive in a crowded market.

However, the rise of automation in the footwear industry does raise concerns about job displacement. While these machines streamline production and improve efficiency, they also reduce the demand for manual laborers. To mitigate these concerns, many companies are investing in retraining programs for their employees, helping them transition to roles that cannot be easily automated, such as quality control, design, and management. By embracing change, the workforce can adapt and thrive in an evolving industry.

In conclusion, automatic shoe sewing machines have transformed the footwear manufacturing process, bringing unprecedented efficiency, quality, and adaptability to the industry. As technology continues to advance, we can expect these machines to become even more sophisticated, shaping the future of shoe production. While challenges regarding employment and adaptation remain, the benefits of automation in enhancing productivity and meeting consumer demands are undeniable. The footwear industry stands on the brink of a new era, driven by innovation and the relentless pursuit of excellence.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025