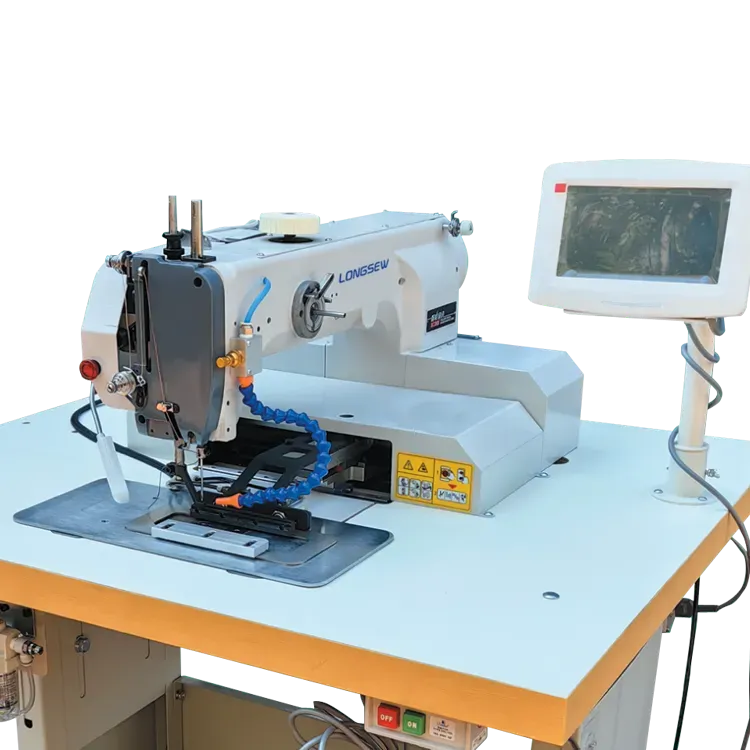

Automatic Tailoring Machine for Efficient Fabric Cutting and Stitching in Modern Garment Production

The Evolution of Tailor Machines Embracing Automation

In a world where efficiency and precision are paramount, the development of automatic tailor machines has revolutionized the textile and fashion industry. These advanced machines not only streamline the sewing process but also open new avenues for creativity and productivity in garment manufacturing. As we explore the concept of the automatic tailor machine, we delve into its significance, technology, and future implications for the industry.

Automatic tailor machines, also known as computerized sewing machines, are designed to enhance the sewing experience by integrating advanced technology with traditional crafting techniques. Unlike their manual predecessors, these machines are equipped with features that allow for high-speed sewing, precise stitching, and the ability to handle various fabrics and patterns effortlessly. This evolution has been fueled by the rising demands for faster production cycles and improved quality control.

The Evolution of Tailor Machines Embracing Automation

Moreover, these machines are often incorporated into sophisticated production lines that utilize artificial intelligence (AI) and machine learning. This technology allows for real-time adjustments based on fabric type, client specifications, and even market trends, making manufacturing more responsive and customizable. For instance, if a certain design is trending on social media, an automatic tailor machine can quickly pivot to produce variations of that design, significantly reducing lead times and aligning production with consumer demand.

tailor machine automatic

The environmental implications of such automation cannot be overlooked. Traditional garment manufacturing is notorious for its wasteful practices, from excess fabric to energy consumption. However, automatic tailor machines can minimize such waste through precise cutting and sewing, optimizing the use of materials. Additionally, their efficiency can lead to reduced energy consumption per article produced, aligning the industry more closely with sustainability goals.

Despite the myriad benefits, the rise of automatic tailor machines has generated concerns around job displacement. As machines take over tasks once performed by skilled artisans, there is a fear that these storied crafts may be lost. However, industry experts argue that automation complements rather than replaces human skill. The need for skilled workers in areas such as machine maintenance, design, and quality control remains crucial, and the focus may shift from repetitive tasks to more creative and strategic roles.

Looking ahead, the future of automatic tailor machines is promising. Continuous advancements in technology will likely introduce even more sophisticated features, enabling further integration with IoT (Internet of Things) applications. Imagine a scenario where machines in a factory communicate seamlessly to optimize production workflows, ensuring that every step, from design to distribution, is synchronized for maximum efficiency.

In conclusion, the emergence of automatic tailor machines marks a significant milestone in the evolution of garment manufacturing. By leveraging advanced technology, these machines are redefining the landscape of the textile industry, promoting efficiency, sustainability, and creativity. As we move forward, the challenge lies in balancing automation with the indispensable human touch that has characterized tailoring for centuries. The future may hold a harmonious blend of both, leading to a new era of fashion that honors tradition while embracing innovation.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025