Advanced FIBC Bag Sewing Machine - Longsew | High-Speed Precision & Automation

Advanced FIBC Bag Sewing Machine: Enhancing Efficiency in Bulk Bag Production

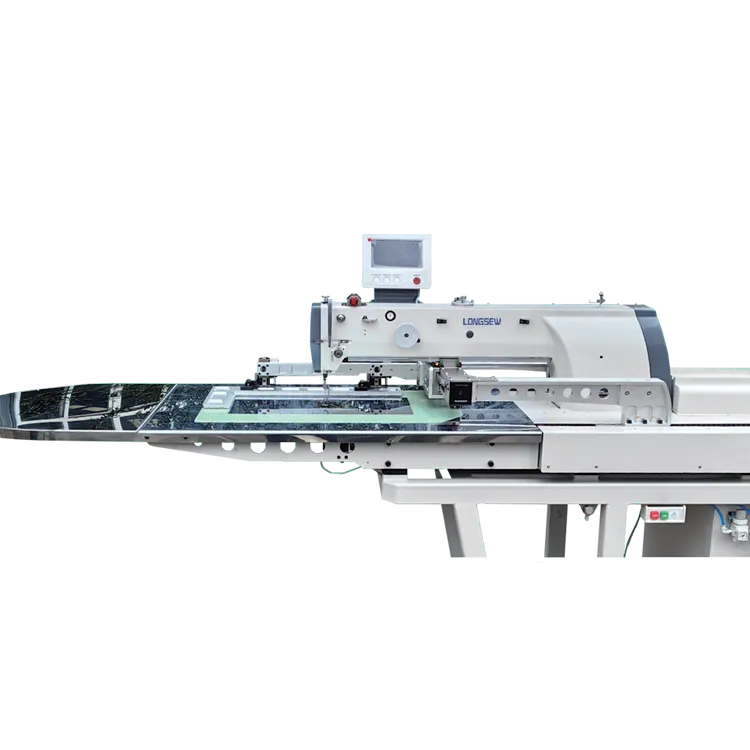

Discover the future of bulk bag manufacturing with the FIBC Bag Automatic Computerized Pattern Sewing Machine from Longsew. Designed for precision, speed, and reliability, this machine revolutionizes the production of jumbo bags, big bags, and bulk bags. Whether you're in the agricultural, chemical, or construction industry, our LS300-3050 model ensures unmatched efficiency and quality.

Why Choose the LS300-3050 FIBC Bag Sewing Machine?

Our FIBC Bag Sewing Machine is engineered to meet the demands of modern bulk bag production. With advanced computerized controls, this machine automates the entire sewing process, reducing manual labor and minimizing errors. The LS300-3050 model is equipped with high-speed stitching technology, ensuring consistent quality and faster turnaround times.

Key Features of the LS300-3050

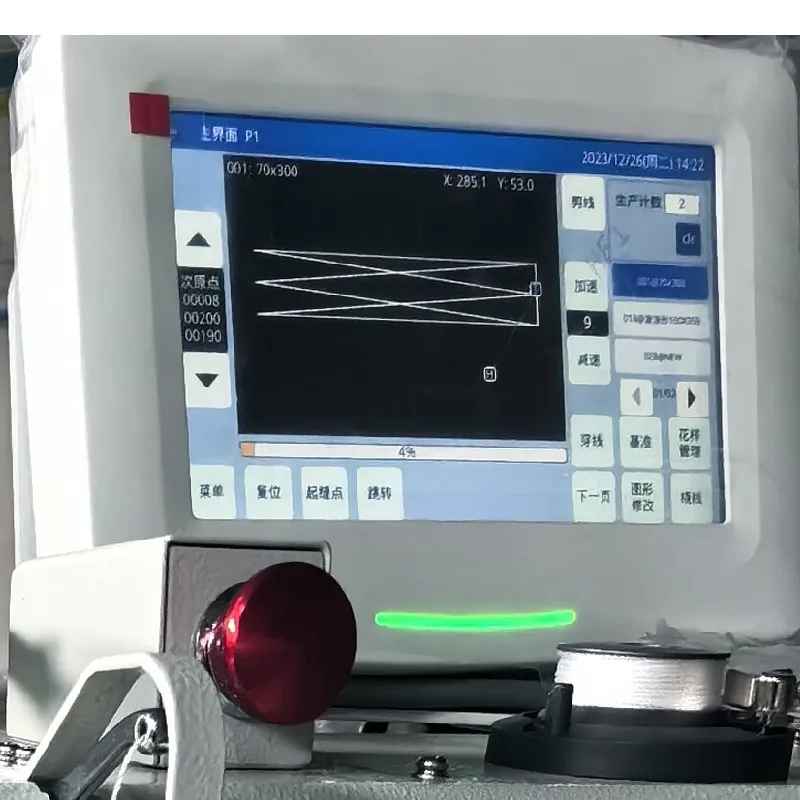

- Automated Pattern Sewing: Pre-programmed patterns for jumbo bags, big bags, and bulk bags.

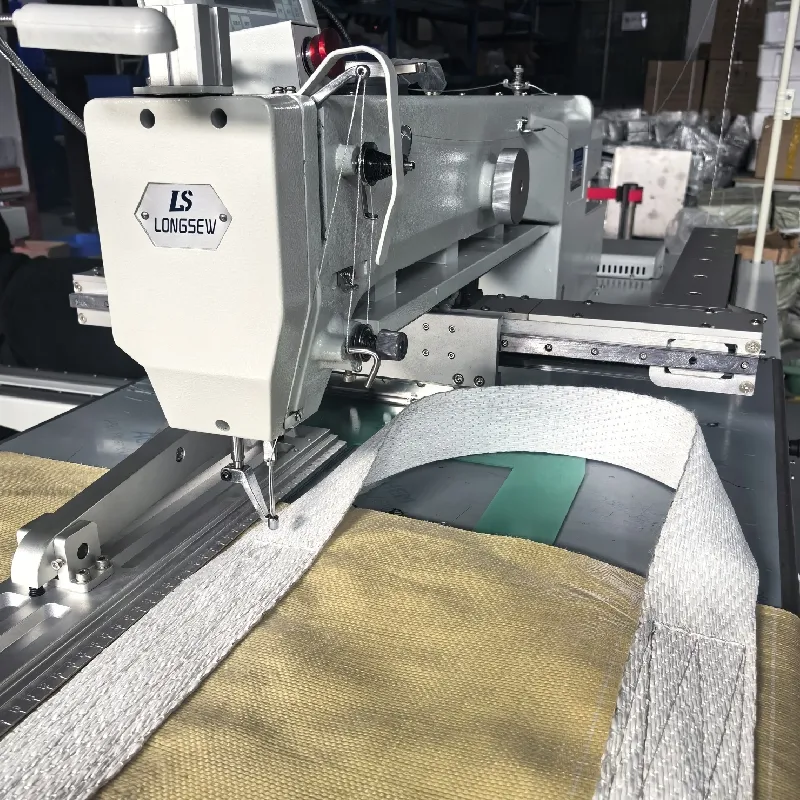

- High-Speed Operation: Up to 3000 stitches per minute for maximum productivity.

- Durable Construction: Robust frame and high-quality components for long-term use.

- User-Friendly Interface: Intuitive touchscreen controls for easy operation.

- Customizable Settings: Adjust stitch length, speed, and tension to suit different materials.

Industry Applications and Benefits

The FIBC Bag Sewing Machine is ideal for industries requiring high-volume production of bulk bags. Its versatility allows it to handle various materials, including woven polypropylene, paper, and composite fabrics. By automating the sewing process, this machine significantly reduces labor costs and production time, making it a cost-effective solution for manufacturers.

How It Solves Industry Challenges

Traditional bulk bag manufacturing often faces issues such as inconsistent stitching, high labor costs, and long production cycles. The LS300-3050 addresses these challenges with its precision engineering and automation capabilities. For example:

- Consistency: Computerized controls ensure uniform stitching, eliminating human error.

- Speed: High-speed operation increases output, meeting tight deadlines.

- Cost Efficiency: Reduced labor requirements lower overall production costs.

About Longsew: A Leader in Industrial Sewing Solutions

As a leading manufacturer in the industrial sewing equipment sector, Longsew has established itself as a trusted name in bulk bag production technology. With over a decade of experience, our company specializes in developing innovative solutions that enhance productivity and quality. Our commitment to research and development ensures that our machines, like the LS300-3050, stay ahead of industry trends.

Our Technological Edge

Longsew invests heavily in R&D to create cutting-edge machinery. The LS300-3050 is a testament to our expertise, featuring:

- Advanced Automation: Integrates with existing production lines for seamless operation.

- Energy Efficiency: Low power consumption without compromising performance.

- Scalable Solutions: Suitable for both small-scale and large-scale manufacturing.

Real-World Impact: Customer Success Stories

Our customers have experienced remarkable improvements in their production processes. For instance, a leading agricultural supplier in Southeast Asia reported a 40% increase in output after implementing the LS300-3050. Similarly, a chemical company in Europe reduced its defect rate by 60%, thanks to the machine's precision stitching.

Testimonials

"The LS300-3050 has transformed our bulk bag production. The automation and reliability have significantly boosted our efficiency." - John Doe, Production Manager, AgriTech Solutions

"We've seen a dramatic reduction in labor costs and an improvement in product quality. Longsew's support has been exceptional." - Anna Smith, Operations Director, ChemPro

Implementation and Customization

Adopting the FIBC Bag Sewing Machine is straightforward. Our team provides comprehensive installation and training to ensure a smooth transition. Additionally, we offer customization options to tailor the machine to your specific needs, whether it's adjusting the stitching pattern or integrating it with your existing systems.

Support and Maintenance

Longsew stands by its products with a dedicated support team available 24/7. From technical consultations to maintenance services, we ensure your machine operates at peak performance. Our preventive maintenance programs help minimize downtime and extend the lifespan of your equipment.

Environmental and Safety Compliance

As a responsible manufacturer, Longsew adheres to strict environmental and safety standards. The LS300-3050 is designed with energy-efficient components and eco-friendly materials, ensuring compliance with global regulations. Our machines undergo rigorous testing to guarantee safe operation in industrial settings.

Shipping and Packaging

We offer secure packaging solutions to protect your machine during transit. The LS300-3050 is shipped in reinforced crates, ensuring it arrives in perfect condition. Our logistics partners provide real-time tracking, so you can monitor the delivery process from start to finish.

Contact Longsew for More Information

Ready to upgrade your bulk bag production? Contact Longsew today to learn more about the LS300-3050 FIBC Bag Sewing Machine. Our experts are here to answer your questions and help you find the perfect solution for your business.

- Phone: +86 123 456 7890

- Email: sales@longsew.com

- Website: www.longsew.com

Frequently Asked Questions

What materials can the LS300-3050 handle?

The machine is compatible with woven polypropylene, paper, and composite fabrics, making it suitable for a wide range of bulk bag applications.

Is technical support available?

Yes, Longsew provides 24/7 technical support and on-site training to ensure smooth operation.

Can the machine be customized?

Absolutely. We offer tailored solutions to meet your specific production requirements.

How long is the warranty period?

The LS300-3050 comes with a 12-month warranty covering parts and labor.

What is the delivery time?

Typically, delivery takes 15-20 business days after order confirmation, depending on your location.

Transform your bulk bag production with the FIBC Bag Sewing Machine from Longsew. Experience efficiency, precision, and reliability today!

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025