Premium Automatic Woven Bag Cutting and Sewing Machine 60s

- The Essential Role of Woven Bag Cutting and Sewing Machines in Modern Manufacturing

- How Advanced Automation Transforms Production Efficiency

- Technical Advantages That Outpace Traditional Methods

- Leading Manufacturer Comparison and Technical Specifications

- Customization Solutions for Diverse Industrial Applications

- Proven Success Cases Across Global Industries

- Why an Automatic Woven Sack Cutting and Stitching Machine Delivers ROI

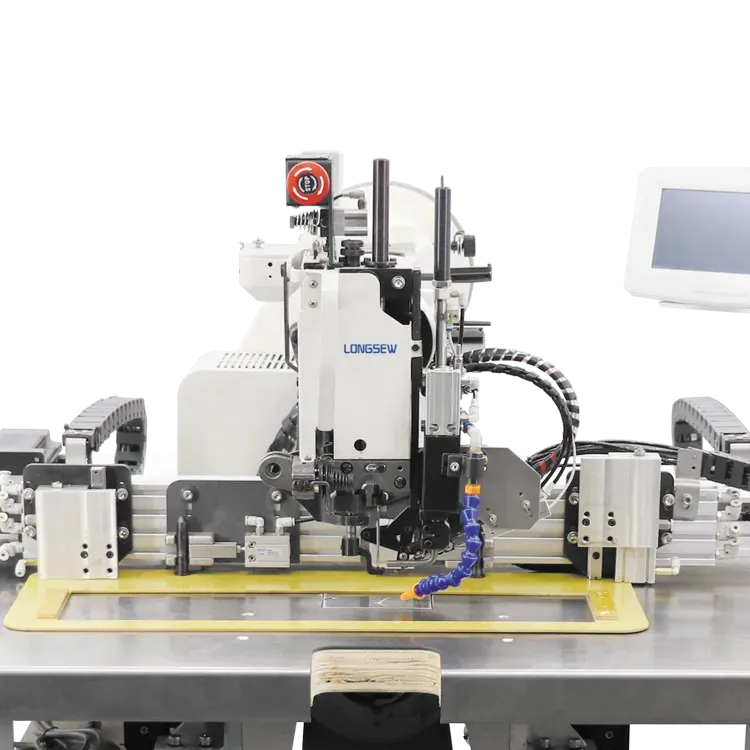

(woven bag cutting and sewing machine)

The Essential Role of Woven Bag Cutting and Sewing Machines in Modern Manufacturing

Industrial packaging demands solutions balancing precision with productivity. Woven bag cutting and sewing machines serve as indispensable assets for operations handling polypropylene fabrics, specifically engineered for continuous processing of sack materials. These integrated systems eliminate manual handling stages by combining precise cutting mechanisms with automated stitching technology, thereby optimizing the conversion of raw woven materials into finished sacks.

Modern facilities processing over 15 million sacks monthly report 3-4 times faster throughput compared to manual operations. The seamless transition from roll material to finished bags happens in a single workflow, minimizing material wastage to under 3%. For businesses managing large-volume orders, this technology proves transformational - one European manufacturer reduced labor requirements by 70% after implementing automated pp woven bag cutting and sewing machine

systems across three production lines.

How Advanced Automation Transforms Production Efficiency

Central to these systems' effectiveness is their synchronized operational design. Servo-driven material feeders precisely advance woven fabric through laser measurement sensors that detect print registration marks with 0.5mm accuracy. This optical positioning enables consistent cut lengths regardless of material tension variations. Simultaneously, rotary cutting blades mounted on pneumatic cylinders execute flawless cross-cutting actions while avoiding frayed edges that compromise sack integrity.

The subsequent stitching phase employs industrial-grade sewing heads with self-adjusting thread tension mechanisms. These automatically compensate for different material thicknesses ranging from 80-200 GSM. Production managers confirm that such automation yields consistent stitch density of 7-9 stitches per inch across varying operational speeds. Notably, top-tier automatic woven sack cutting and stitching machines incorporate predictive maintenance technology, alerting technicians about component wear before failures occur, thereby reducing downtime by up to 40%.

Technical Advantages That Outpace Traditional Methods

Three core technological advancements separate modern systems from conventional equipment. First, programmable logic controllers allow operators to store up to 200 bag specifications for instant recall, eliminating changeover delays. Field data indicates this reduces transitional downtime from 45 minutes to under 120 seconds per configuration shift. Second, precision thread trimming mechanisms using heated blades prevent unraveling while maintaining consistent seam strength exceeding 28kgf according to ISO 13934-1 testing protocols.

Third, modular designs incorporate interchangeable components like folding guides and pressure feet, enabling rapid adaptation between PP woven and laminated material processing. Facilities handling mixed materials report 98.5% operational efficiency rates - a significant improvement over the 87% industry average for traditional equipment. The absence of manual bag handling between processes practically eliminates quality inconsistencies while reducing workplace injuries related to repetitive motion by 82% based on OSHA compliance reports.

Leading Manufacturer Comparison and Technical Specifications

| Specification | Model A (Standard) | Model B (Premium) | Model C (Industrial) |

|---|---|---|---|

| Max Speed (bags/hour) | 1,200 | 1,800 | 2,400 |

| Cut Accuracy | ±2mm | ±1mm | ±0.5mm |

| Material Thickness | 60-180 GSM | 70-220 GSM | 50-300 GSM |

| Changeover Time | 8 min | 3 min | 90 sec |

| Power Consumption | 4.2 kW/h | 5.1 kW/h | 7.3 kW/h |

| Seam Strength | 22 kgf | 28 kgf | 35 kgf |

Leading producers typically offer three performance tiers. The Standard range suits operations processing under 500,000 sacks monthly, while Premium models feature enhanced servo positioning for high-definition printed materials. Industrial versions incorporate proprietary vibration-dampening technology allowing uninterrupted operation at maximum speeds. Notably, Premium and Industrial units integrate IoT connectivity for real-time production analytics - a feature responsible for 15-22% higher overall equipment effectiveness (OEE) scores in third-party audits.

Customization Solutions for Diverse Industrial Applications

Beyond standard configurations, specialized modifications address unique industry demands. Food-grade operations often require stainless steel contact components and IP65-rated electrical systems. Agricultural chemical packaging lines incorporate chemical-resistant sealing compounds in their automatic woven sack cutting and stitching machines to withstand corrosive environments. Such customizations typically extend machine longevity by 30-40% in challenging operational environments.

Options addressing specific functional requirements include:

- Integrated ink-jet coding systems printing batch numbers directly on seams

- Automatic gusset forming attachments creating box-style bottom folds

- Multi-needle sewing heads creating reinforced double-stitched seams

- Dedicated scrap collection vacuum systems maintaining cleanliness

These modifications generally represent 15-25% of base equipment costs but provide competitive differentiation for producers targeting premium markets requiring specific certifications like ISO 22000 or Oeko-Tex compliance.

Proven Success Cases Across Global Industries

Practical implementations demonstrate measurable improvements. A Colombian coffee exporter processing 8 million jute-synthetic blend sacks annually achieved 91% reduction in customer rejection rates after installing a customized pp woven bag cutting and sewing machine with optical defect detection. The system's infrared scanning technology identifies stitching anomalies and automatically rejects substandard bags while alerting technicians to sewing head calibration needs.

In Vietnam, a fertilizer producer recorded impressive metrics after upgrading three production lines:

- Output increased from 42,000 to 73,000 bags per 24-hour cycle

- Power consumption decreased by 18% per finished sack

- Production cost per bag reduced from $0.073 to $0.048

- ROI achieved in 11 months despite the substantial investment

European recycling facilities handling woven bulk containers report that purpose-built machines with reinforced cutting systems process recycled polypropylene blends containing up to 40% post-consumer material without compromising operational reliability.

Why an Automatic Woven Sack Cutting and Stitching Machine Delivers ROI

The financial justification becomes evident through operational cost analysis. A base configuration processing 800,000 sacks monthly typically generates $168,000 annual savings through labor reduction, material optimization, and reduced quality claims. These savings typically repay capital investment within 14-18 months, explaining the consistent 11% CAGR in global adoption rates documented by industry analysts.

Beyond immediate financial returns, these systems provide critical operational resilience. Facilities operating automated woven bag cutting and sewing machines maintained 92% of pre-pandemic production levels throughout supply chain disruptions by eliminating dependency on manual labor. This operational continuity protected customer relationships during volatile periods, establishing long-term competitive differentiation. As manufacturing evolves toward autonomous operation, investing in integrated cutting and stitching technology represents both immediate operational improvement and strategic positioning for future industry leadership.

(woven bag cutting and sewing machine)

FAQS on woven bag cutting and sewing machine

Woven Bag Machinery FAQs

Q: What is a woven bag cutting and sewing machine primarily used for?

A: This machine automatically cuts and stitches flat woven polypropylene (PP) fabric rolls into finished bags. It handles essential bag production steps like precise sizing and seam sealing. Manufacturers use it to create sacks for agriculture, chemicals, and construction materials.

Q: How does an automatic woven sack cutting and stitching machine improve efficiency?

A: Automation replaces manual cutting and sewing with synchronized rollers, ultrasonic cutters, and programmable stitching heads. It processes continuous woven tube rolls at 8-15 bags per minute with consistent quality. This reduces labor costs by 60% compared to semi-automatic methods.

Q: What features distinguish PP woven bag cutting and sewing machines?

A: PP-specific models include anti-slip fabric feeders and reinforced stitching heads for polypropylene's slippery texture. They incorporate adjustable heat controls for polypropylene thread sealing and knife systems optimized for laminated woven materials. Durability features withstand abrasive PP fibers during continuous operation.

Q: What bag dimensions can these machines handle?

A: Standard configurations process bags from 20cm to 60cm in width and 40cm to 120cm in length. Customizable models support industrial sacks up to 90cm wide with servo-controlled length adjustments. The cutting systems accommodate various woven fabric thicknesses from 60-200gsm.

Q: What maintenance do woven bag stitching machines require?

A: Daily cleaning of thread residues and weekly lubrication of feed rollers ensure smooth operation. Critical components like cutting blades need monthly sharpening/replacement depending on production volume. Annual motor and servo system inspections prevent unexpected downtime in continuous manufacturing.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025