Feb . 10, 2025 23:10

Back to list

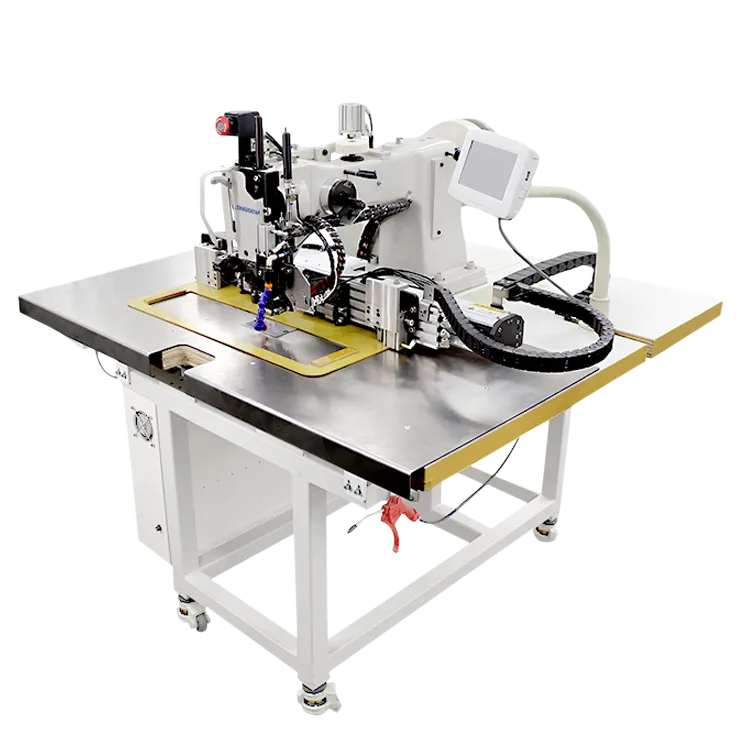

Heavy Duty Computerized Auto Pattern Sewing Machine For Safety Rope or Safety Belt LS273-2010H / LS273-2010S

Choosing the right upholstery sewing machine for leather is crucial for anyone serious about quality craftsmanship. Leather, with its unique properties, demands specialized tools that cater to its texture and thickness. This article provides a thorough insight into the world of upholstery sewing machines designed specifically for leatherworking, leveraging expertise and real-world experience to help you make an informed decision.

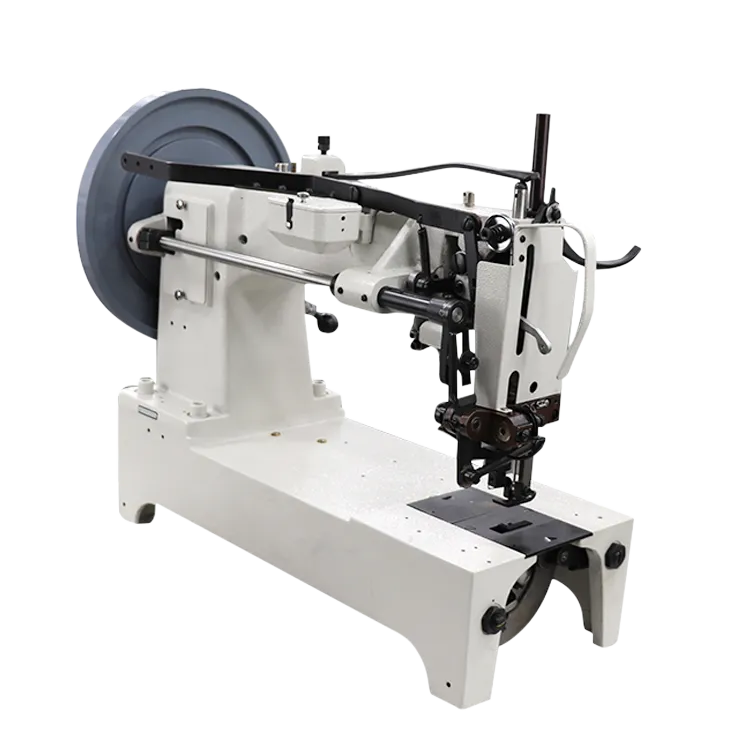

An often overlooked yet valuable feature is the presence of a large throat space. This attribute provides ample room to maneuver large leather pieces, reducing strain and increasing precision. Machines designed with extended workspaces accommodate embellishments and detailed work, enhancing your overall productivity and comfort. Technical support and warranty from manufacturers play a significant role in your overall satisfaction. Opt for brands with a reputation for quality customer service and robust warranty policies. Resources such as user forums, professional reviews, and direct feedback from fellow craftsmen provide authentic insights into real-world machine performance, bolstering trustworthiness and authority. Consider the availability of accessories and replacement parts specific to leatherworking. Having a variety of presser feet, needles, bobbins, and stitch plates easily accessible can significantly impact your workflow and project versatility. Brands such as Singer and Juki are renowned in the leather upholstery field, offering models like the Singer Heavy Duty 4452 and Juki DNU-1541. These models exemplify the convergence of powerful motors, robust builds, and specialized features suited for leather. Incorporating experience and expertise, along with trustworthiness and authoritativeness, ensures your buying decision for an upholstery sewing machine is well-informed. Each project may require unique features, so recognizing your specific needs is imperative. Whether you're upgrading your current setup or venturing into leather upholstery, making an informed choice will elevate both your craftsmanship and your satisfaction. Lastly, regular maintenance is key to ensuring the longevity and performance of your chosen machine. Routine oiling, timely needle replacements, and cleaning are essential practices that maintain the machine’s integrity and stitching quality, extending the lifespan of both your machine and your crafted leather pieces.

An often overlooked yet valuable feature is the presence of a large throat space. This attribute provides ample room to maneuver large leather pieces, reducing strain and increasing precision. Machines designed with extended workspaces accommodate embellishments and detailed work, enhancing your overall productivity and comfort. Technical support and warranty from manufacturers play a significant role in your overall satisfaction. Opt for brands with a reputation for quality customer service and robust warranty policies. Resources such as user forums, professional reviews, and direct feedback from fellow craftsmen provide authentic insights into real-world machine performance, bolstering trustworthiness and authority. Consider the availability of accessories and replacement parts specific to leatherworking. Having a variety of presser feet, needles, bobbins, and stitch plates easily accessible can significantly impact your workflow and project versatility. Brands such as Singer and Juki are renowned in the leather upholstery field, offering models like the Singer Heavy Duty 4452 and Juki DNU-1541. These models exemplify the convergence of powerful motors, robust builds, and specialized features suited for leather. Incorporating experience and expertise, along with trustworthiness and authoritativeness, ensures your buying decision for an upholstery sewing machine is well-informed. Each project may require unique features, so recognizing your specific needs is imperative. Whether you're upgrading your current setup or venturing into leather upholstery, making an informed choice will elevate both your craftsmanship and your satisfaction. Lastly, regular maintenance is key to ensuring the longevity and performance of your chosen machine. Routine oiling, timely needle replacements, and cleaning are essential practices that maintain the machine’s integrity and stitching quality, extending the lifespan of both your machine and your crafted leather pieces.

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025