Understanding the Purpose and Applications of Cylinder Arm Sewing Machines in Textile Production

Understanding Cylinder Arm Sewing Machines What Are They Used For?

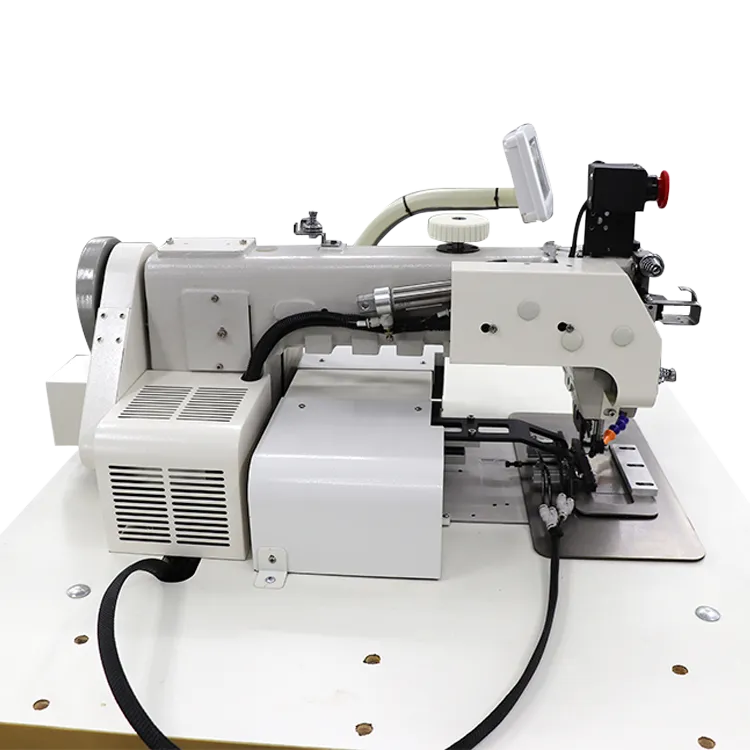

In the world of sewing and garment production, various types of machines serve specific purposes to enhance efficiency and improve the quality of the final product. One such specialized machine is the cylinder arm sewing machine. This device is particularly designed for sewing tubular or cylindrical pieces of fabric, making it an invaluable tool in various industries, especially in the creation of garments.

Structure and Functionality

The key distinguishing feature of a cylinder arm sewing machine is its unique arm design. Unlike standard flatbed sewing machines, which have a flat surface on which fabric lays, the cylinder arm machine has a cylindrical arm that allows for greater maneuverability. This unique structure enables seamstresses and tailors to sew intricate designs on hard-to-reach areas, such as sleeves, cuffs, collars, and necklines. The machine is particularly beneficial for sewing garments with tubular parts, including T-shirts, pants, and dresses, where accessing the interior sections can be challenging.

Versatility in Application

Cylinder arm sewing machines are widely used in the apparel manufacturing industry. Their versatility allows them to handle various types of fabrics, from lightweight materials like cotton and silk to heavier fabrics such as denim and canvas. This versatility makes them ideal for producing a wide range of products, including athletic wear, outerwear, and uniforms.

what is a cylinder arm sewing machine used for

One of the most significant advantages of a cylinder arm machine is its ability to create high-quality seams in difficult areas. For instance, when sewing sports jerseys, a cylinder arm machine can navigate the curved lines of the sleeves, ensuring that the seams are strong yet flexible. This is crucial in sportswear, where comfort and durability are paramount. Additionally, these machines can perform a variety of stitch types, including straight, zigzag, and overlock stitches, making them suitable for both construction and finishing tasks.

Efficiency and Productivity

In a manufacturing setting, the efficiency of sewing operations directly impacts productivity. Cylinder arm sewing machines are typically faster than traditional machines when it comes to sewing tubular pieces, as they enable operators to manipulate fabric more easily. This efficiency can lead to faster turnaround times for orders, which is crucial in the fast-paced fashion industry.

Moreover, the ergonomic design of cylinder arm machines can reduce strain on operators, as they do not need to contort their bodies to reach difficult areas of the fabric. This design can lead to improved worker satisfaction and reduced fatigue, further enhancing productivity levels.

Conclusion

In summary, the cylinder arm sewing machine is an essential tool in the garment manufacturing industry, specifically designed to tackle the challenges associated with sewing tubular fabric pieces. Its unique structure allows for exceptional maneuverability, enabling seamstresses to create high-quality seams in areas that might otherwise be difficult to access. The versatility in handling various fabric types and stitch styles further underscores its importance. As the demand for intricate and high-quality garments continues to grow, the cylinder arm sewing machine will undoubtedly remain a staple in sewing operations, contributing to both efficiency and excellence in fabric processing. Whether in small tailor shops or large-scale manufacturing facilities, this machine plays a pivotal role in the art and science of sewing.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025