Versatile Machines for Tent Fabrication and Repair Solutions

The art of tent sewing has evolved over the years, transforming from a manual, labor-intensive process into a more efficient and precise operation thanks to the innovation of the tent sewing machine. These specialized machines are designed to handle heavy-duty fabrics like canvas, nylon, and polyester, making them essential for creating tents used in camping, outdoor events, and military applications.

Tent sewing machines are characterized by their robust construction and advanced features that cater to the challenges of working with thick materials. Unlike regular sewing machines, which might struggle or even break under the pressure of heavy fabrics, tent sewing machines are equipped with powerful motors and heavy-duty needles. This allows them to easily stitch through multiple layers of fabric, ensuring durability and strength in seams.

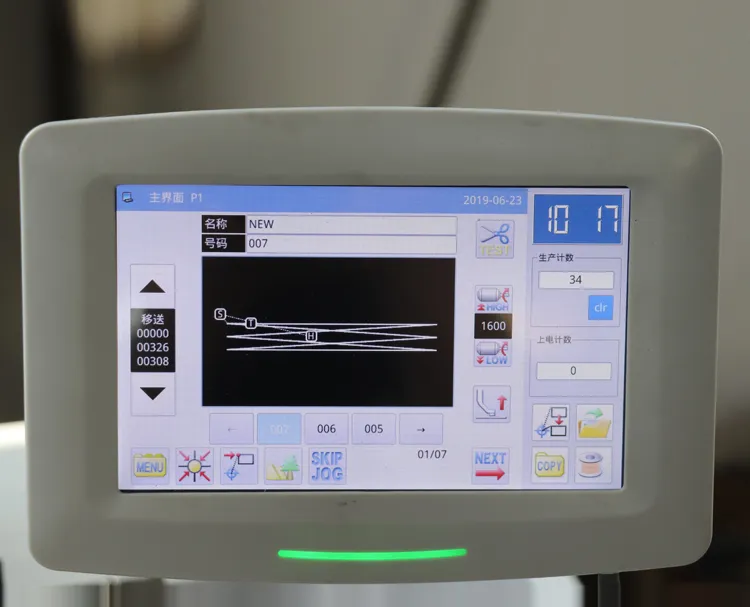

One of the key advantages of using a tent sewing machine is the efficiency it brings to the manufacturing process. Traditional methods of sewing tents often involve lengthy manual labor, which can lead to inconsistencies in quality and longer production times. With a tent sewing machine, manufacturers can produce high-quality tents more quickly, meeting the growing demand in the market. Some machines even come with automated features, such as programmable pattern stitching, which further enhances productivity and precision.

In addition to speed and efficiency, tent sewing machines also support a variety of stitching techniques

. Manufacturers can choose from multiple stitch patterns—like straight, zigzag, or reinforcing stitches—to suit different designs and applications. This versatility is crucial for making tents that need to withstand various weather conditions and stresses, as reinforced seams and strong stitches contribute to the overall integrity of the tent.tent sewing machine

Moreover, the availability of specialized feet and attachments for tent sewing machines allows users to achieve even more specialized tasks. For example, walking feet can help to evenly feed multiple layers of thick fabric, preventing any slipping that may lead to misaligned seams. This attention to detail in the sewing process is essential for creating tents that provide the best possible protection from the elements.

As outdoor activities continue to gain popularity, the demand for high-quality tents is projected to rise. Consequently, the tent sewing machine market is likely to innovate further, integrating advanced technologies such as computerized controls and improved fabric handling systems. These advancements will not only enhance sewing efficiency but also enable manufacturers to create more sophisticated designs that appeal to a broad range of consumers.

In conclusion, the tent sewing machine plays a crucial role in the manufacturing of tents, combining speed, efficiency, and versatility. As technology continues to evolve, we can expect these machines to become even more advanced, helping produce tents that meet the demands of an increasingly outdoor-loving society. Whether it’s for camping, festivals, or emergency situations, the importance of tent sewing machines in ensuring quality and durability cannot be overstated.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025