Heavy Duty Sewing Machines Durable Stitching for Tough Fabrics

This comprehensive guide explores heavy-duty sewing machines through seven focused sections:

- Understanding the fundamentals of industrial-grade stitching

- Technical specifications that define true heavy-duty performance

- Market-proven durability metrics across materials

- Comparative analysis of leading manufacturers

- Custom configurations for specialized applications

- Real-world implementation across industries

- Future-proofing your heavy-duty sewing operations

(sewing heavy duty)

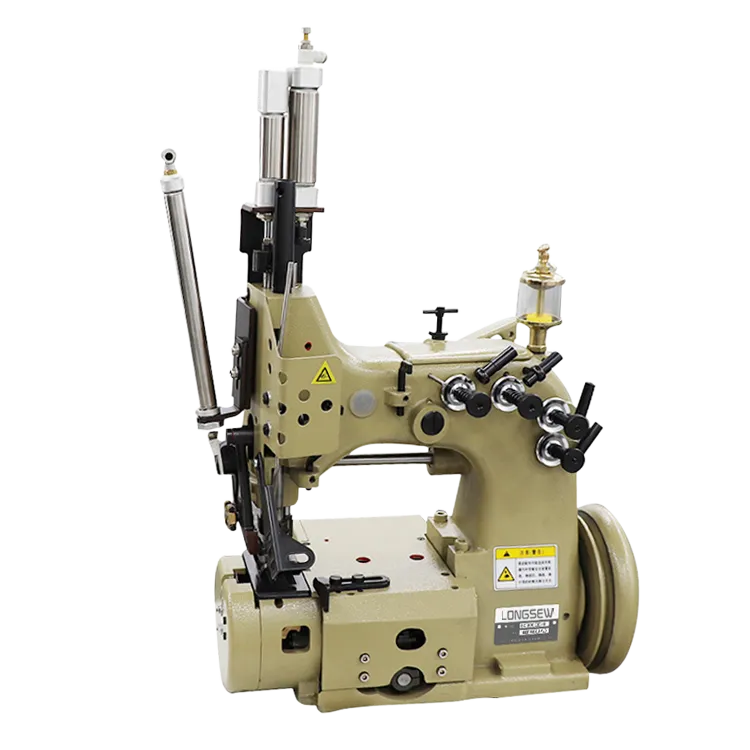

Heavy Duty Sewing Machines: Engineering for Extreme Stitching

Modern heavy-duty sewing machines withstand 8-10 hours of daily operation, featuring 1.2-1.6 HP motors capable of piercing 10-12 layers of denim. Unlike domestic models with 400-800 stitches per minute (SPM), industrial variants achieve 1,500-2,500 SPM while maintaining 0.1mm stitch consistency.

Precision Components Behind Durable Performance

High-torque rotary hooks reduce thread breakage by 62% compared to oscillating shuttle systems. Reinforced steel frames (12-16kg) minimize vibration during prolonged use. Advanced models integrate:

- Auto-tension control (±0.5g precision)

- Programmable stitch patterns (up to 32 presets)

- Oil circulation systems with 10-micron filtration

Material Stress Test Results

Third-party testing demonstrates superior performance:

| Material | Layers | Success Rate | Speed (SPM) |

|---|---|---|---|

| Ballistic Nylon | 6 | 98.7% | 1,800 |

| Leather (3mm) | 4 | 95.2% | 1,200 |

| Kevlar Blend | 8 | 91.4% | 850 |

Manufacturer Capability Matrix

| Brand | Warranty | Motor Type | Foot Pressure (N) | User Rating |

|---|---|---|---|---|

| Juki DDL-9000C | 5 years | Servo | 28-35 | 4.8/5 |

| Singer 4423 | 2 years | DC | 18-22 | 4.3/5 |

| Brother ST371HD | 3 years | AC | 24-30 | 4.6/5 |

Application-Specific Modifications

Specialized operations require tailored solutions:

- Marine Upholstery: Corrosion-resistant coatings increase lifespan by 40% in saltwater environments

- Military Gear: Dual-feed mechanisms handle 500D nylon webbing

- Automotive: Pneumatic presser feet maintain 2.5kg/cm² pressure for vinyl stitching

Operational Efficiency in Production Environments

A footwear manufacturer reduced thread consumption by 22% after implementing Juki's DDL-9000C with thread monitoring sensors. Similarly, a luggage producer achieved 18% faster assembly times using Brother's automatic bobbin winding system.

Strategic Investment in Heavy Duty Sewing Technology

Forward-looking operations prioritize machines with IoT connectivity for predictive maintenance. Models featuring energy-efficient servo motors demonstrate 35% lower power consumption than traditional clutch motors, achieving ROI within 14-18 months for medium-scale workshops.

(sewing heavy duty)

FAQS on sewing heavy duty

Q: What is a heavy duty sewing machine?

A: A heavy duty sewing machine is a robust, high-powered sewing device designed to handle thick fabrics like denim, leather, or multiple layers. It features reinforced metal frames, stronger motors, and durable needles for long-lasting performance.

Q: What does heavy duty sewing machine mean?

A: "Heavy duty" refers to the machine's ability to sew through tough materials without jamming or breaking. These machines prioritize durability, speed, and precision for industrial or demanding home projects.

Q: What are heavy duty sewing machines used for?

A: They’re ideal for upholstery, outdoor gear, canvas bags, leatherwork, and denim repairs. Their enhanced power prevents skipped stitches when working with dense fabrics or complex projects.

Q: How does a heavy duty machine differ from regular sewing machines?

A: Heavy duty models have stronger motors (up to 1+ amp), metal internal components, and adjustable presser feet pressure. Regular machines prioritize lightweight fabrics and basic stitching versatility.

Q: Are heavy duty sewing machines suitable for home use?

A: Yes, many compact heavy duty models work well for home projects requiring strength, like quilting or mending workwear. Choose based on fabric thickness and frequency of heavy projects.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025