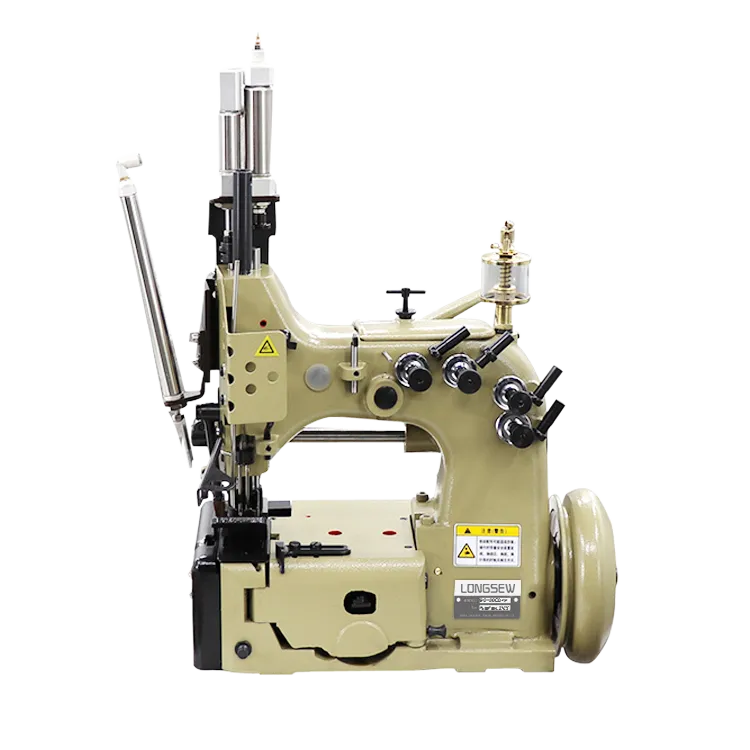

pp bag sewing machine

The Rise of PP Bag Sewing Machines A Comprehensive Overview

In recent years, the demand for sustainable and eco-friendly packaging solutions has surged, leading to the prominence of polypropylene (PP) bags in various industries. As a result, the machinery required to produce these bags, specifically the PP bag sewing machine, has also gained significant attention. This article aims to explore the features, benefits, and applications of PP bag sewing machines, as well as the impact they have on the packaging industry.

What is a PP Bag Sewing Machine?

A PP bag sewing machine is specially designed to stitch polypropylene bags, which are widely used for packaging grains, fertilizers, sugar, and various other products. These machines enable manufacturers to produce durable, sturdy bags that are not only functional but also cost-effective. The sewing machines can handle different types and thicknesses of PP material, making them versatile tools in various manufacturing settings.

Key Features of PP Bag Sewing Machines

1. Durability and Strength PP bag sewing machines are engineered to provide robust stitching, ensuring that bags can withstand the rigors of transport and handling. The strength of the seams is crucial as it prevents tear and rupture during use.

2. High-Speed Operation Many modern PP bag sewing machines are equipped with high-speed capabilities, allowing manufacturers to significantly increase their production rates. High-speed sewing reduces production time and enhances overall efficiency.

3. User-Friendly Controls Advanced models come with easy-to-use control panels that enable operators to adjust settings quickly. Features such as automatic thread cutting and digital displays enhance usability, making it easier for operators to manage production.

4. Versatility These machines can be configured to sew various types of bags—whether they are open-mouth, valve bags, or pre-formed. The versatility allows manufacturers to diversify their product offerings without investing in multiple types of machinery.

5. Energy Efficiency With a growing emphasis on sustainability, many manufacturers are also focusing on creating energy-efficient machines. Advanced technology in sewing machines can reduce power consumption while maintaining high performance.

pp bag sewing machine

Benefits of Using PP Bag Sewing Machines

1. Cost-Effectiveness Sewing PP bags is more economical compared to other packaging methods. With the ability to produce large quantities of durable bags in a short period, manufacturers can lower their overall production costs.

2. Sustainable Packaging Solution As the world shifts towards environmentally friendly practices, PP bags offer a sustainable alternative to traditional plastic bags. They are recyclable and have a lower environmental impact, aligning with the goals of many businesses striving for sustainability.

3. Adaptability to Market Trends With the ability to quickly adjust production to meet consumer demands, companies can stay ahead in a competitive marketplace. PP bag sewing machines allow manufacturers to respond efficiently to changing market needs.

4. Enhancements in Product Quality When using high-quality sewing machines, manufacturers can ensure that their bags meet industry standards. This boosts customer satisfaction and strengthens brand loyalty.

Applications of PP Bag Sewing Machines

PP bag sewing machines find applications across many sectors, including but not limited to

- Agriculture Used to package seeds, fertilizers, and animal feed, ensuring that they are secure during transport and storage. - Food Industry Ideal for packaging grains, sugar, and other bulk food items, preserving their quality while providing convenience. - Construction Commonly employed for packaging construction materials like cement and sand, where bag strength is critical. - Retail and Distribution Used for packaging various products, from pet food to gardening supplies, catering to a wide range of consumer needs.

Conclusion

The PP bag sewing machine has become an essential tool in the production line for various industries. Its ability to produce durable, cost-effective, and sustainable packaging solutions positions it as a key player in the modern manufacturing landscape. As consumers and businesses alike continue to prioritize sustainability and efficiency, investing in advanced PP bag sewing machines is a strategic move for manufacturers looking to thrive in an evolving marketplace. With ongoing technological advancements, the future of PP bag sewing machines appears bright, promising even greater innovations to meet the demands of the global market.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025