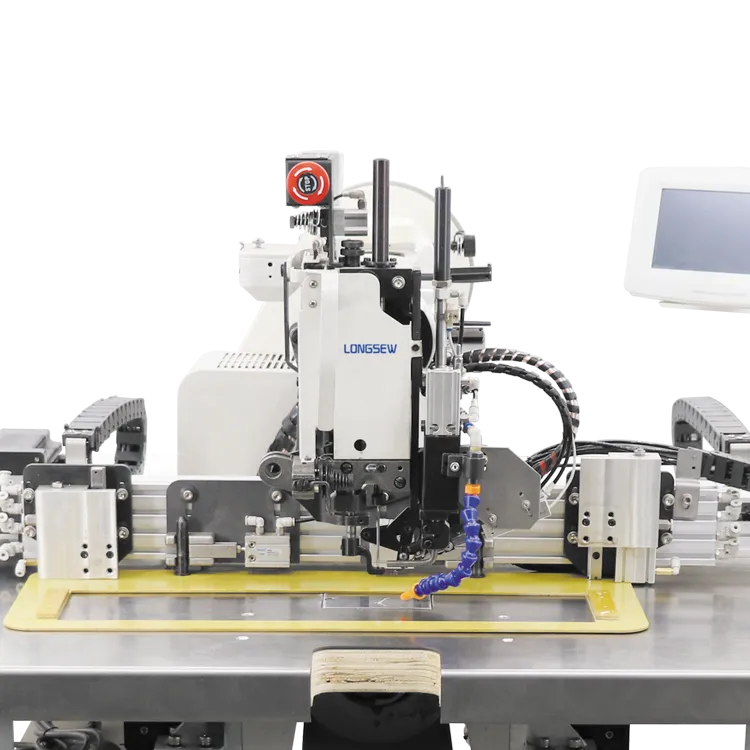

pattern sewing machine for shoes

The Evolution and Importance of Pattern Sewing Machines for Shoe Production

In the realm of footwear manufacturing, the efficiency and precision of production processes are paramount. One of the most significant advancements in this domain is the introduction of pattern sewing machines for shoes. These machines have revolutionized the way shoes are designed and produced, enabling manufacturers to keep up with the ever-increasing demand for quality footwear.

The Mechanics of Pattern Sewing Machines

Pattern sewing machines are specialized tools designed to sew intricate patterns onto various materials used in shoe manufacturing. Unlike traditional sewing machines, which are generally limited to straight or zigzag stitches, pattern sewing machines are equipped with advanced technology that allows for the automated creation of complex designs. They utilize computer-aided design (CAD) systems to precisely replicate patterns, ensuring uniformity and reducing human error.

These machines often come with various attachments and features that enhance their capabilities. For instance, they may include walking feet, differential feed, and specialized needles to handle different materials, whether leather, synthetic fabrics, or canvas. The ability to adjust settings based on the material and design makes these machines indispensable in the modern shoe production line.

The Advantages of Using Pattern Sewing Machines

1. Increased Efficiency One of the primary benefits of pattern sewing machines is their ability to significantly increase production speed. Traditional methods of sewing intricate designs often require skilled labor and substantial time. In contrast, pattern sewing machines can automate this process, allowing for faster turnaround times without compromising quality.

2. Precision and Consistency In footwear production, consistency is key. Consumers expect shoes to maintain specific aesthetic and functional standards. Pattern sewing machines excel in providing precision stitching that is consistent across all units produced. This uniformity not only enhances the overall quality of the footwear but also fosters a positive brand reputation.

pattern sewing machine for shoes

3. Design Versatility The use of pattern sewing machines opens up a world of possibilities in shoe design. Designers can experiment with various styles and patterns, knowing they can be seamlessly translated into the final product. From intricate embroidery to bold graphic designs, the capability of these machines to execute complex patterns allows brands to stand out in a competitive market.

4. Reduced Labor Costs While the initial investment in pattern sewing machines may be significant, the long-term savings on labor costs can be substantial. By automating parts of the production process, manufacturers can reduce the number of skilled laborers required on the shop floor, reallocating resources to areas that require human oversight or creative input.

The Future of Pattern Sewing Machines in Footwear

As technology continues to evolve, pattern sewing machines are embracing innovations that further enhance their functionality. For example, advancements in artificial intelligence and machine learning may lead to even more sophisticated pattern recognition and execution capabilities. These improvements will not only increase efficiency but also allow for greater customization options, catering to the unique preferences of individual consumers.

Moreover, sustainability is becoming increasingly crucial in the footwear industry. Future pattern sewing machines may integrate eco-friendly practices, such as reducing materials waste through precise cutting and sewing techniques or using sustainable fabrics. This trend will likely resonate with conscientious consumers and could provide manufacturers with a competitive edge.

Conclusion

In conclusion, pattern sewing machines represent a pivotal development in the footwear manufacturing industry. Their ability to enhance efficiency, precision, and design versatility makes them invaluable assets for modern shoemakers. As technology continues to advance, we can expect pattern sewing machines to evolve further, playing a vital role in meeting the demands of both manufacturers and consumers in an ever-changing market. Investing in these machines is not just a step towards modernization; it is a commitment to quality, innovation, and sustainability in footwear production.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025