Overview of Feeder Foot Functionality in Sewing Machines

The Versatility and Efficiency of Feeder Foot Sewing Machines

In the realm of textile and garment manufacturing, efficiency and precision are paramount. Among the various tools and techniques used by professionals, the feeder foot sewing machine stands out as a significant innovation. This machine enhances the sewing process, offering an array of benefits that cater to both large-scale industrial needs and smaller, personalized projects.

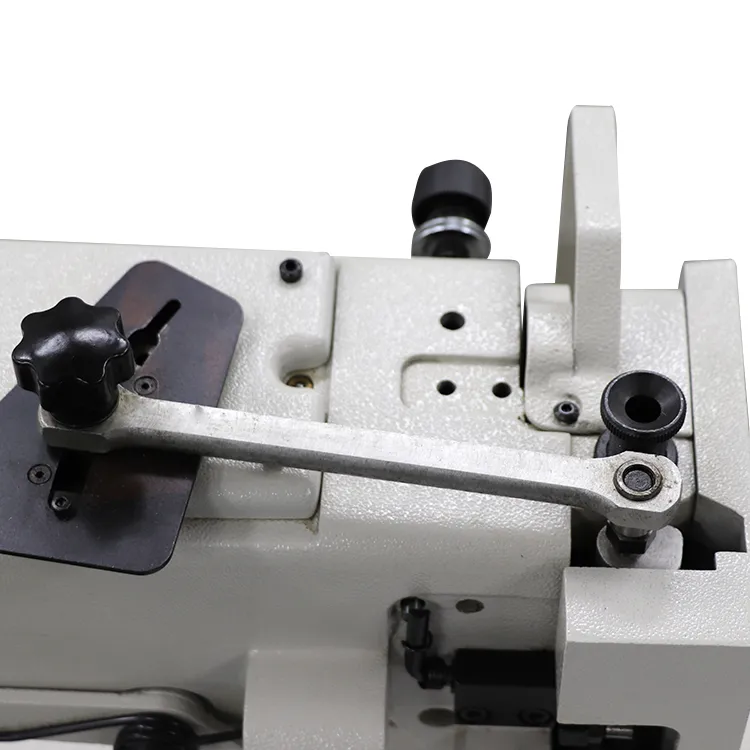

A feeder foot sewing machine, often referred to as a walking foot or even a dual feed machine, features a unique mechanism that allows the presser foot to move in tandem with the feed dogs. This synchronization helps to manage the feeding of multiple layers of fabric easily, preventing any slippage or misalignment, which can be crucial when working with delicate or slippery materials like silk or satin. The ability of the feeder foot to grip the fabric means that users can achieve a uniform stitch regardless of the type of material being used.

One of the key advantages of employing a feeder foot sewing machine is its versatility. These machines are capable of handling a diverse range of fabrics and thicknesses, from lightweight garments to heavy upholstery or canvas. This makes them ideal for various applications including quilting, leatherwork, and garment construction. As such, both professional tailors and hobbyists can benefit from the consistent results provided by this specialized equipment.

Moreover, feeder foot machines are designed to enhance creative freedom. When sewing thick or multi-layered fabrics, traditional machines can struggle and result in uneven seams or fabric puckering. However, with a feeder foot sewing machine, crafters can execute complex designs and techniques, including binding, topstitching, and quilting with ease. The smooth feeding action also opens up possibilities for more intricate patterns and embellishments, allowing for a greater artistic expression in textile creation.

feeder foot sewing machine

Another significant benefit is the efficiency savings these machines provide. By reducing the potential for errors and rework, they enable seamstresses and tailors to complete projects in a fraction of the usual time. This increased productivity is particularly essential in a commercial setting where time is money. For small business owners, using a feeder foot sewing machine can mean producing higher-quality products faster while reducing material waste.

In addition to their operational advantages, feeder foot sewing machines also demonstrate durability and reliability. Built to withstand rigorous use, many models feature robust construction and high-quality components that ensure longevity. When investing in sewing equipment, durability is a critical factor, particularly for businesses that rely on heavy daily use.

For those considering a switch to a feeder foot sewing machine, it is essential to research the various options available in the market. Today, there are numerous models catering to different skill levels and needs, from basic machines suitable for beginners to advanced machines with multiple functions for seasoned professionals. Features to consider include adjustable stitch length, needle positioning, and even computerized capabilities that can make sewing projects easier and more enjoyable.

In conclusion, the feeder foot sewing machine is a remarkable tool in the textile industry, providing efficiency, precision, and creative possibilities. Whether used in a professional workshop or a home sewing room, it can significantly elevate the sewing experience, making it easier to achieve high-quality results. As the sewing landscape continues to evolve, machines that enhance productivity while allowing for creative expression are invaluable assets for anyone passionate about sewing.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025