Comprehensive Guide to Operating a Manual Leather Stitching Machine for Optimal Results

The Art of Manual Leather Stitching A Comprehensive Guide to Mastering the Leather Stitching Machine

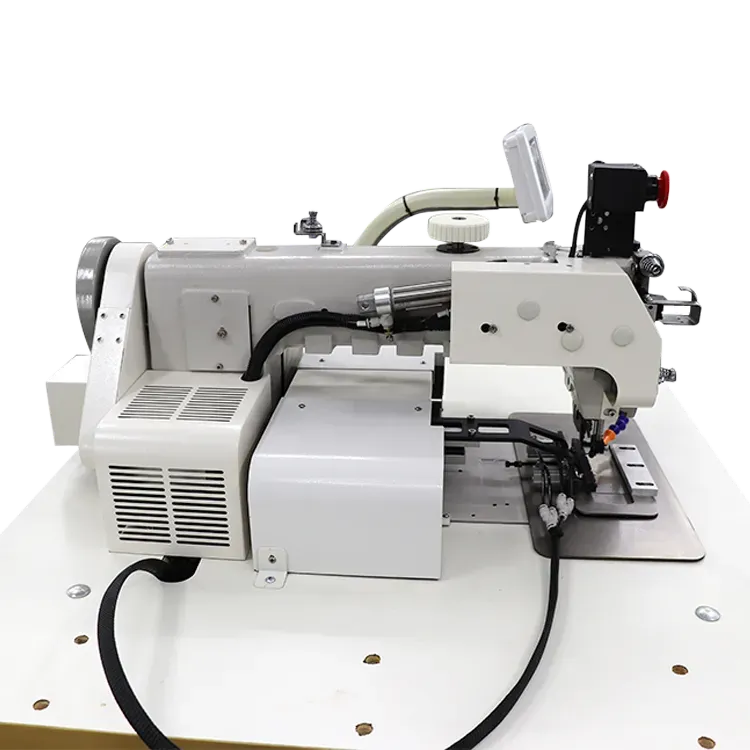

Leather crafting has long been revered as an art form, combining craftsmanship, creativity, and a deep appreciation for quality materials. One of the most essential tools in a leatherworker's arsenal is the manual leather stitching machine. This remarkable device not only facilitates precise stitching but also allows artisans to imbue their creations with a personal touch. In this article, we will explore the intricacies of using a manual leather stitching machine, its benefits, and how to master its operation.

Understanding the Manual Leather Stitching Machine

A manual leather stitching machine is designed to handle tough materials, ensuring strong and lasting seams. Unlike its electric counterparts, which can sometimes be intimidating for beginners, the manual machine offers greater control and a more intimate connection with the crafting process. This type of machine typically features a hand crank or lever, allowing the user to alternate between feeding the leather and controlling the stitching speed.

Most manual leather stitching machines operate by using two needles that create a lock stitch formation. This method not only enhances the strength of the seam but also provides an aesthetically pleasing appearance. The machine is capable of stitching various thread thicknesses, making it versatile for different leather weights and types.

Benefits of Manual Leather Stitching Machines

1. Precision Manual machines allow for greater control over the stitching process. Artisans can determine the length of each stitch, ensuring uniformity across their projects.

2. Durability A properly stitched seam using a manual machine contributes to the longevity of the item. This is crucial in leather crafting, where products are often subjected to wear and tear.

3. Flexibility The manual machine can accommodate different types of threads and leather, making it an excellent choice for diverse projects, from wallets to bags and belts.

manual leather stitching machine

4. Cost-Effectiveness Investing in a manual leather stitching machine can be more economical in the long run. It requires less maintenance and fewer repairs compared to electric machines.

Getting Started with Your Manual Leather Stitching Machine

1. Setting Up Begin by ensuring that your machine is correctly set up according to the manufacturer's guidelines. This includes threading the needles, adjusting tension, and selecting the appropriate stitch length.

2. Preparing Your Leather Cut your leather pieces with precision, making sure that edges are clean and even. This will contribute to a professional-looking finished product.

3. Choosing the Right Thread Select a thread that matches the weight of your leather. Heavier leather requires thicker thread for optimal results.

4. Practicing Your Technique Before diving into your project, take the time to practice on scrap pieces of leather. This will help you gain confidence in operating the machine and understanding the stitch formation.

5. Finishing Touches Once your stitching is complete, consider trimming excess threads and applying edge finishing products to enhance the overall look of your creation.

Conclusion

Mastering the manual leather stitching machine is a rewarding endeavor that can elevate your leather crafting skills. By understanding the machine's operation and benefits, you can create beautiful, durable products that reflect your unique style. Whether you are a hobbyist or an aspiring professional, investing time in learning this craft will undoubtedly pay off in the quality and longevity of your leather goods. So gather your tools, roll out your leather, and embark on a journey of creativity and craftsmanship that will leave a lasting impression.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025