Exploring the Benefits of Lock Stitch Sewing Machines for Seamstress Projects

Understanding Lock Stitch Sewing Machines

Sewing has evolved significantly over the years, with various techniques and machinery developing to meet the needs of both hobbyists and professionals. Among these innovations, the lock stitch sewing machine has become a staple in the textile industry due to its efficiency and versatility. This article explores the workings, advantages, and applications of lock stitch sewing machines.

What is a Lock Stitch?

A lock stitch is created by interlocking two threads - the top (needle) thread and the bottom (bobbin) thread. When the needle penetrates the fabric, it carries the upper thread down through the material while the bobbin thread works from below. This unique interlocking method ensures a strong, secure stitch that is commonly used in a wide range of sewing applications. The lock stitch is distinguished by its neat appearance on both the front and back sides of the fabric, making it ideal for various projects.

How Do Lock Stitch Sewing Machines Work?

Lock stitch sewing machines typically feature two key components a needle and a bobbin case. The needle, driven by a motorized mechanism, pierces the fabric and pulls the top thread through the material. Simultaneously, the bobbin, located below the needle plate, releases the bottom thread through a series of movements, creating the lock stitch as the threads interlock at the fabric's surface.

Most modern lock stitch machines are equipped with additional features such as automatic thread tension adjustment, stitch length control, and programmable stitch patterns. These advancements allow for greater precision and flexibility, accommodating different fabric types and sewing techniques.

Advantages of Lock Stitch Sewing Machines

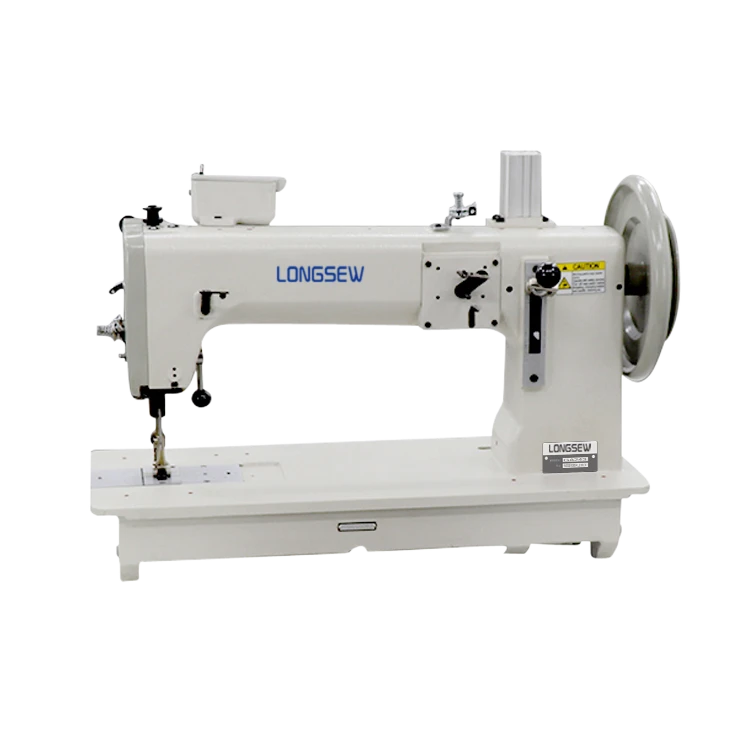

lock stitch sewing machine

One of the primary benefits of lock stitch sewing machines is their reliability. The locked threads provide a stronghold, making them suitable for various fabrics, from lightweight silks to heavy denim and leather. Not only do they create durable seams, but lock stitches also maintain their integrity even under tension, which is crucial for items like clothing and upholstery.

Another advantage is the versatility of lock stitch machines. They can be used for basic sewing tasks like hemming and garment assembly, as well as more complex applications like quilting and embroidery. This machine can handle both straight and zig-zag stitches, making it a valuable asset for any sewing enthusiast or professional.

Applications in the Industry

Lock stitch sewing machines are widely used in the garment manufacturing industry, where rapid production and quality stitching are crucial. They can efficiently create seams in T-shirts, dresses, pants, and outerwear. Moreover, their consistent performance makes them a preferred choice in other sectors, including furniture and automotive industries, for sewing upholstery and fabric coverings.

In addition to industrial applications, lock stitch sewing machines are popular among home sewers. Many domestic models are equipped with features that cater to beginners and advanced users alike, providing a platform for creativity and skill development.

Conclusion

Lock stitch sewing machines represent an essential aspect of modern sewing, combining technology with tradition to produce high-quality results. Their ability to create strong, reliable stitches makes them indispensable in various industries, from fashion to home décor. Whether you are a professional tailor or a casual sewing enthusiast, understanding and utilizing a lock stitch sewing machine can enhance your sewing experience and open doors to endless creative possibilities. With ongoing advancements in sewing technology, the future of lock stitch sewing machines continues to hold exciting potential for innovation and efficiency in textile production.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025