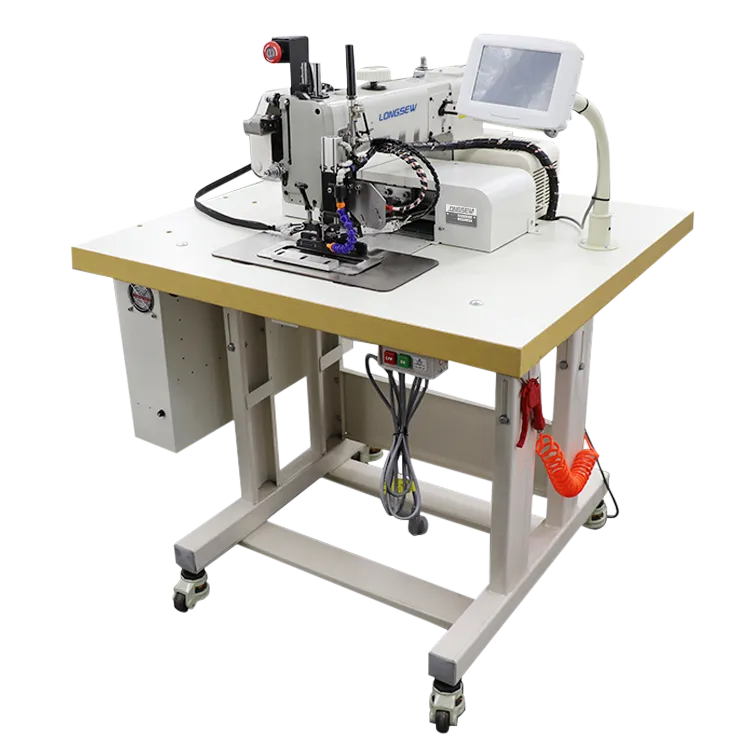

jute bag closer machine

Jute Bag Closer Machine An Essential Tool for Sustainable Packaging

In recent years, the global emphasis on sustainability and eco-friendliness has stimulated the growth of industries focused on natural and biodegradable materials. Among these, jute has emerged as a prominent player, particularly in the field of packaging. As the demand for jute bags escalates, so does the need for efficient machinery to support their production and closure. Enter the jute bag closer machine, a crucial innovation in the realm of sustainable packaging.

Understanding Jute and Its Applications

Jute is a natural fiber derived from the jute plant, primarily grown in warm, humid climates. It is inexpensive, biodegradable, and known for its strength and durability, making it an ideal material for bags and packaging solutions. Jute bags have found applications in various sectors, including agriculture, retail, and food packaging. Their ability to reduce plastic waste has made them a preferred choice for environmentally conscious consumers and businesses alike.

The Role of Jute Bag Closer Machines

The production of jute bags involves a series of steps, from weaving the fabric to cutting and sewing it into bag shapes. However, one of the most critical stages is the closing of the bags after they have been filled. This is where the jute bag closer machine comes into play. These machines are designed to streamline the closing process, ensuring that the bags are securely sealed, thus preventing spillage of the contents and maintaining quality.

Efficiency and Speed One of the primary advantages of a jute bag closer machine is its efficiency. Traditional methods of sealing bags, such as hand stitching or manual tying, can be labor-intensive and time-consuming. In contrast, machines can rapidly close a large number of bags, significantly increasing production rates. This capability is especially beneficial for manufacturers handling high volumes of jute bags.

Consistent Quality In addition to speed, jute bag closer machines ensure a consistent quality of sealing. Human error in manual processes can result in uneven seals or missed closures, leading to compromised product safety. Machines, on the other hand, deliver uniform results every time, which is crucial for maintaining quality standards and customer satisfaction.

Cost-Effectiveness Investing in a jute bag closer machine can also be cost-effective in the long run. While the initial purchase price may be a consideration, the reduction in labor costs and the increase in production capacity can lead to significant savings. Furthermore, the long lifespan of these machines makes them a worthwhile investment for jute bag manufacturers.

Types of Jute Bag Closer Machines

jute bag closer machine

There are various types of jute bag closer machines available in the market, each serving specific needs. Some of the most common types include

1. Sewing Machines Designed for stitching jute bags, these machines provide a strong and durable closure, essential for heavy-duty bags used in agriculture and transportation.

2. Heat Sealing Machines These machines use heat to seal the edges of jute bags, offering a quick and efficient way to close bags without the need for additional materials like thread.

3. Staple Machines These are used for stapling closures, providing a straightforward and effective method for sealing jute bags, particularly for lighter content.

4. Automatic Bag Closing Machines These advanced machines incorporate technology to fully automate the closing process, allowing for maximum efficiency and minimal manual intervention.

The Future of Jute Bag Closing Technology

As the demand for jute bags continues to rise, so does the innovation in jute bag closing technology. Manufacturers are exploring advancements such as automation, smart technology integration, and enhanced energy efficiency. These developments not only improve the overall functionality of the machines but also align with the sustainability values of the jute industry.

Conclusion

In conclusion, jute bag closer machines play a pivotal role in the sustainable packaging sector. They contribute to the efficiency, quality, and cost-effectiveness of jute bag production. As the world shifts towards more sustainable practices, the importance of such machinery cannot be overstated. By facilitating the growth of jute as a viable packaging solution, these machines support both manufacturers and consumers in their quest for environmentally friendly alternatives to plastic. Embracing these innovations is essential for a greener future, one jute bag at a time.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025