Industrial Sewing Machines for Straight and Zigzag Stitching Versatility and Performance

The Versatility of Industrial Sewing Machines Straight and Zigzag Stitches

In the realm of textile manufacturing, industrial sewing machines play a pivotal role in the production of garments and various fabric goods. Among the multitude of stitches these machines can perform, straight and zigzag stitches are arguably the most fundamental and widely used. Understanding the applications and advantages of these stitches is crucial for anyone involved in fashion design, garment production, or textile engineering.

Straight Stitch The Foundation of Sewing

The straight stitch is the most basic and prevalent stitch type, forming the foundation of most sewing projects. It is characterized by a simple, linear formation created by a single thread passing through the fabric. This stitch is invaluable due to its strength and durability, making it suitable for a wide array of fabrics, from lightweight cotton to heavy denim.

In industrial settings, straight stitches are predominantly used for seaming, topstitching, and hemming. The ability to adjust stitch length allows manufacturers to customize the strength and flexibility of the seam, which is particularly important in garments that require movement, such as activewear. Additionally, the straight stitch is essential in creating clean and professional finishes, contributing to the overall quality of the final product.

Industrial sewing machines equipped with straight stitch capabilities can operate at high speeds, increasing productivity in a factory setting. Features such as automatic thread tensioning, programmable stitch lengths, and needle positioning further enhance efficiency, making the process not only faster but also more precise.

Zigzag Stitch Flexibility and Functionality

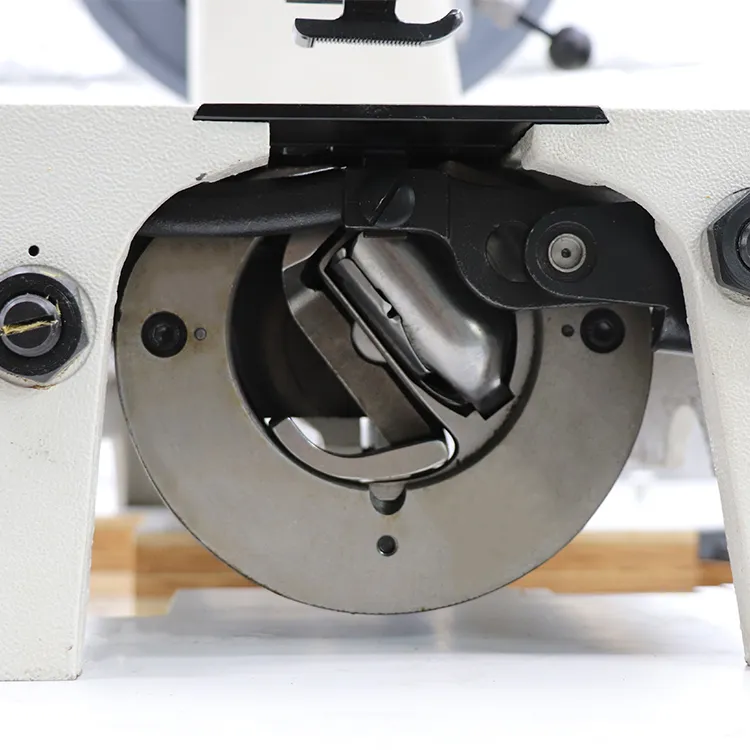

industrial sewing machine straight and zig zag

While the straight stitch is the backbone of sewing, the zigzag stitch adds versatility and functionality to garment construction. As the name suggests, this stitch creates a zigzag pattern, which allows for greater stretch and adaptability. This characteristic makes the zigzag stitch particularly useful for knit fabrics, where flexibility is key.

Zigzag stitches serve multiple purposes in garment manufacturing. They are commonly utilized for finishing seams, preventing fraying, and providing decorative elements in designs. The stitch's ability to stretch makes it ideal for use on areas of garments that experience movement, such as armholes and waistbands. Moreover, zigzag stitches can also be applied to create buttonholes, as they provide the necessary reinforcement while accommodating the button's movement.

In industrial sewing, machines that perform zigzag stitching are often equipped with advanced features, such as adjustable stitch width and length, allowing designers to create varied effects. These machines facilitate creativity and innovation in fashion, enabling the production of unique and intricate designs.

Conclusion Choosing the Right Machine

When it comes to selecting the appropriate industrial sewing machine, understanding the distinctions between straight and zigzag stitches is vital. While straight stitch machines are fundamental for basic construction and finishing, zigzag machines offer the flexibility needed for more complex designs. Many modern industrial sewing machines can combine both functionalities, providing operators with the capability to switch between stitch types as needed.

Investing in high-quality industrial sewing machines designed for straight and zigzag stitches can significantly enhance production efficiency and product quality. As the textile industry continues to evolve, the significance of these basic stitches persists, underpinning the intricate and diverse world of garment manufacturing. Whether constructing a simple dress or a complex activewear ensemble, the mastery of straight and zigzag stitches remains essential for ensuring a high standard of craftsmanship in the final product.

In conclusion, straight and zigzag stitches form the backbone of industrial sewing, encompassing both simplicity and versatility. Understanding their functions allows manufacturers to optimize production processes and deliver innovative textile solutions that meet the demands of today's ever-changing fashion landscape.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025