Features and Benefits of Straight and Zigzag Stitch Industrial Sewing Machines

The Versatility of Industrial Sewing Machines Straight and Zigzag Stitches

Industrial sewing machines are vital tools in the textile and garment industries, known for their ability to operate at high speeds and produce high-quality work. Among the various types of stitching capabilities offered by these machines, straight and zigzag stitches are two of the most essential. Understanding their functions, applications, and benefits is crucial for anyone involved in manufacturing or sewing.

Straight Stitches The Foundation of Sewing

The straight stitch is the most fundamental sewing technique and serves as the backbone for many sewing projects. This stitch is executed by moving the fabric straight under the needle, allowing seamless seams to be formed. The straight stitch is particularly favored for its strength and durability, making it ideal for sewing basic seams in woven fabrics, creating hems, and reinforcing areas that endure stress.

Moreover, straight stitches can also be adjusted for different purposes. For instance, a longer stitch is often used for basting—temporary stitching to hold fabric together before final sewing—while a shorter stitch provides more strength and is ideal for seams that will undergo significant strain. In industrial settings, the efficiency of straight stitch machines allows for rapid production, making them an indispensable part of garment manufacturing, upholstery, and other fabric-related industries.

Zigzag Stitches Adding Flexibility and Design

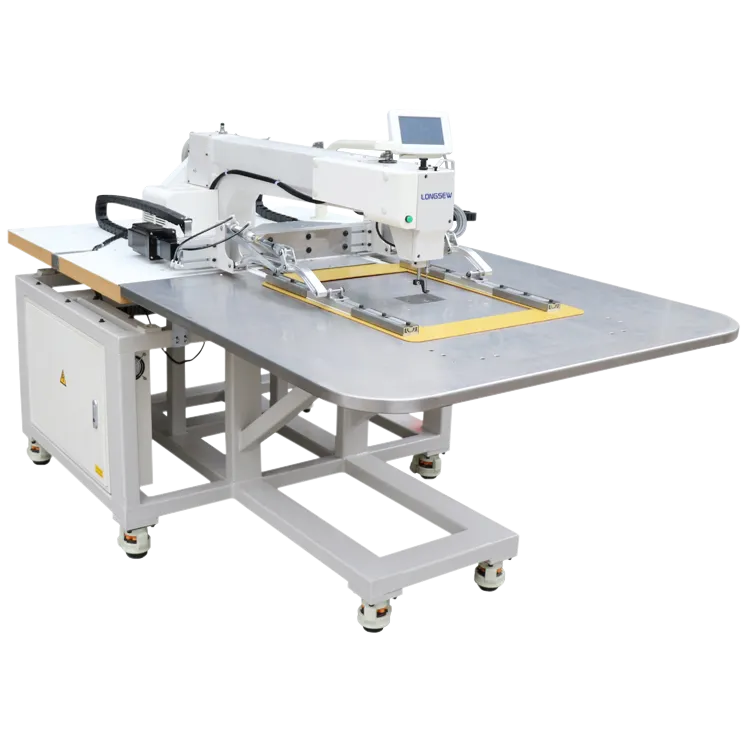

industrial sewing machine straight and zig zag

In contrast to the straight stitch, the zigzag stitch is characterized by its side-to-side motion, creating a wave-like pattern. This stitch offers incredible versatility and is used for various applications beyond mere seam construction. The zigzag stitch is particularly effective for sewing stretch fabrics, as it allows the fabric to maintain its elasticity. This is crucial in the production of athletic wear, lingerie, and other garments requiring flexibility.

Additionally, zigzag stitches serve decorative purposes. They can be used to embellish seams, add visual interest to the fabric, and create intricate designs without the need for specialized embroidery machines. This stitch can also help in preventing fabric fraying by encasing the edge, which is a common concern with woven materials. For industrial designers and manufacturers, the ability to create attractive and durable seams simultaneously is a significant advantage.

Conclusion Choosing the Right Machine for Your Needs

When considering an industrial sewing machine, the choice between models that specialize in straight vs. zigzag stitching may depend on the intended application. Straight stitch machines offer efficiency and strength for basic seam construction, while zigzag machines provide versatility and creative possibilities. Ultimately, both types of stitches play a vital role in modern textile manufacturing, helping to shape the industry and cater to various customer needs.

Investing in an industrial sewing machine that can handle both straight and zigzag stitches ensures not only versatility but also the ability to tackle a wide range of projects, from everyday clothing to intricate designs, making it a valuable asset for any sewing operation.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025