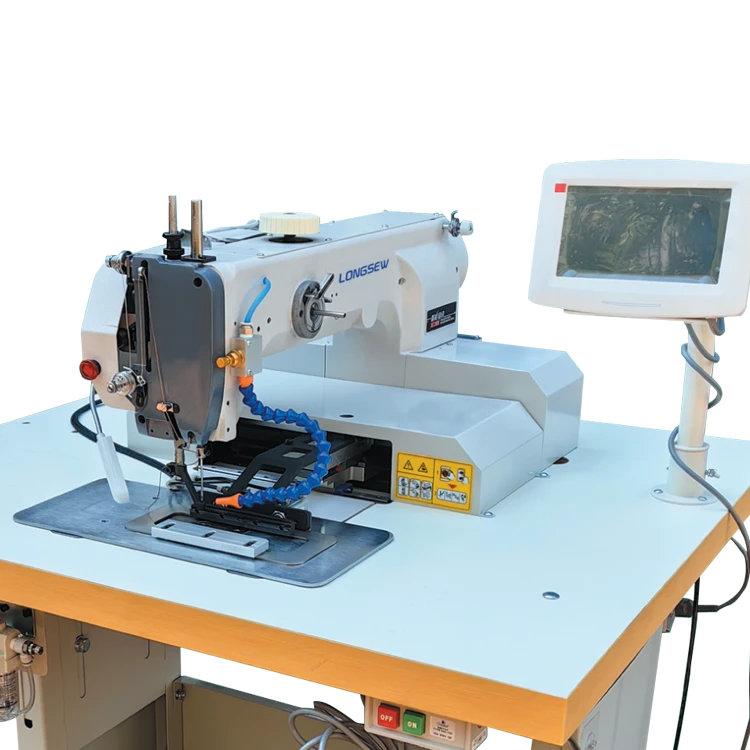

industrial bag closer sewing machine

The Importance of Industrial Bag Closer Sewing Machines in Modern Manufacturing

In the fast-paced world of manufacturing and production, efficiency and precision are paramount. One particularly vital component in this industry is the industrial bag closer sewing machine. These machines are essential for a wide variety of applications, particularly in industries where bags are used to package products, such as food, agriculture, and materials handling. Understanding the significance, functionality, and advancements in bag closer sewing machines sheds light on their crucial role in modern manufacturing.

What is an Industrial Bag Closer Sewing Machine?

An industrial bag closer sewing machine is a specialized device designed to securely stitch the open ends of bags once they are filled. These bags can come in various materials, including woven polypropylene, paper, and burlap, and are typically used for packaging grains, animal feed, chemicals, and other bulk products. The primary purpose of these machines is to ensure that the bags remain closed during storage and transportation, thereby preventing spillage and contamination.

Key Features and Advantages

Industrial bag closer sewing machines are engineered for high performance and durability. They often feature robust construction to withstand the rigors of continuous operation. Some of the key features include

1. Speed and Efficiency These machines are designed to operate at high speeds, often stitching thousands of bags per hour. This capability significantly boosts production rates and minimizes downtime. 2. Versatility Many models can handle various bag sizes and materials, making them suitable for different applications. This adaptability is crucial for manufacturers who deal with a range of products.

3. Ease of Use Modern bag closer sewing machines are equipped with user-friendly controls and mechanisms that facilitate quick adjustments. This simplicity helps operators to maintain productivity levels even during busy shifts.

4. Durability Built for heavy-duty use, these machines have reinforced parts and advanced threading systems that reduce wear and tear, ensuring longevity and reducing maintenance costs.

industrial bag closer sewing machine

5. Quality Stitching High-quality stitching is essential for bag integrity. Industrial bag closer sewing machines utilize advanced feed systems that evenly tension the thread, resulting in strong and consistent seams.

The Role in Quality Control

In industries where product integrity is crucial, such as food and pharmaceuticals, the reliability of bag closures is of utmost importance. A malfunctioning or poorly sealed bag can lead to significant losses, product contamination, and safety issues. Industrial bag closer sewing machines ensure consistent, high-quality closures that meet regulatory standards and consumer expectations.

Technological Advancements

Advancements in technology have also revolutionized bag closer sewing machines. Modern devices may include features such as electronic controls, programmable stitch patterns, and even automated feeding systems. These innovations not only enhance efficiency but also improve the precision of the stitching process. Furthermore, the integration of sensors and diagnostic displays allow for real-time monitoring of machine performance, enabling quick troubleshooting and reducing downtime.

The Future of Industrial Bag Closing

As the demand for packaged goods continues to rise, particularly in e-commerce and global trade, the need for reliable and efficient bag closure solutions will only grow. Manufacturers are increasingly looking for machines that not only meet current demands but are also adaptable for future needs. The trend towards automation and smart manufacturing will likely see further advancements in bag closer technologies, including the potential for full automation and integration with production lines.

Conclusion

In summary, industrial bag closer sewing machines play a crucial role in the manufacturing sector, ensuring that products are safely packed and transported. Their high efficiency, durability, and adaptability make them indispensable tools in various industries. As technology continues to evolve, the future of bag closer sewing machines promises to bring even more enhancements, further solidifying their position within the manufacturing landscape. For manufacturers, investing in quality bag closer sewing machines is not just a necessity, but a strategic advantage in optimizing production processes and ensuring product quality.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025