Advanced Heavy Tailoring Machinery for Precision Crafting and Customization Solutions

The Evolution and Impact of Heavy Tailoring Machines

In the world of garment manufacturing and textile processing, heavy tailoring machines have carved out a pivotal role. These specialized machines are designed to handle thick, dense fabrics, making them essential for producing high-quality garments, upholstery, and heavy-duty textiles. As industries continue to evolve, the demand for efficiency and precision has led to significant advancements in the technology behind heavy tailoring machines.

Understanding Heavy Tailoring Machines

Heavy tailoring machines are specifically engineered to sew and manipulate thicker materials that standard sewing machines may struggle with. They typically feature robust motor systems, enhanced needle mechanisms, and stronger feed mechanisms to ensure seamless operation on heavy fabrics like denim, canvas, and leather. These machines can perform various stitching operations, including straight stitching, zigzag stitching, and decorative sewing, allowing for versatility in production.

Historical Context

The journey of heavy tailoring machines began with the industrial revolution when the demand for faster production methods grew. Initially, machines were manually operated and limited in scope. With the introduction of electric motors in the 20th century, these machines became more efficient, reducing labor costs and increasing output.

The 1970s and 1980s marked a significant turning point with the advent of computerized sewing technology. These innovations allowed for greater precision in stitching patterns and the ability to program complex designs, further enhancing the capabilities of heavy tailoring machines. The integration of computer-aided design (CAD) systems transformed the garment industry, allowing designers to visualize and manipulate their creations effectively.

Key Features and Innovations

Modern heavy tailoring machines boast an array of features designed for enhanced performance. One of the most notable advancements is the introduction of servo motors, which provide greater control over the speed and power of the machine. This results in improved accuracy and less fabric distortion during the sewing process.

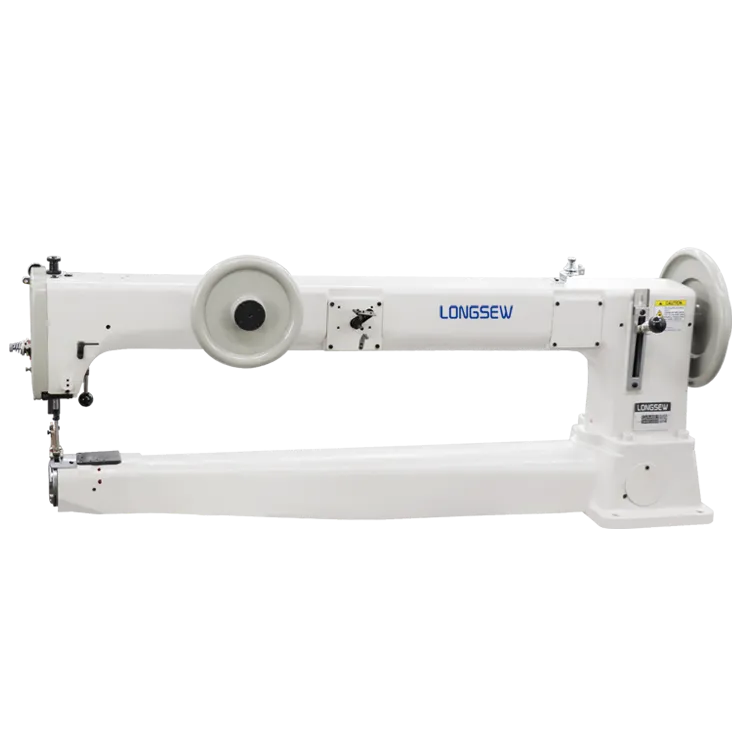

heavy tailoring machine

Additionally, advancements in needle technology have enabled manufacturers to produce specialized needles that cater to a variety of heavy fabrics. These needles can withstand the rigors of sewing through multiple layers of material, reducing breakage and downtime.

Moreover, the incorporation of automatic threading systems and built-in tension controls has significantly reduced setup times and improved the overall efficiency of garment production. With the ability to switch between different settings quickly, operators can adapt to varying fabric types without compromising quality.

Industry Applications

Heavy tailoring machines are indispensable in various industries, including fashion, upholstery, and automotive manufacturing. In the fashion industry, they are used to create everything from designer jackets to durable workwear, ensuring that garments can withstand the demands of everyday use.

In upholstery, these machines facilitate the crafting of resilient furniture coverings that must endure wear and tear while maintaining aesthetic appeal. The automotive industry relies on heavy tailoring machines for sewing components like seat covers and internal linings, underscoring their versatility and necessity.

The Future of Heavy Tailoring Machines

As technology advances, the future of heavy tailoring machines looks promising. The integration of artificial intelligence and machine learning is expected to further revolutionize the industry, allowing machines to learn from patterns and optimize sewing processes in real time. Moreover, sustainability in textile production is becoming a focal point, prompting innovations that reduce waste and enhance energy efficiency.

In conclusion, heavy tailoring machines have evolved significantly, shaping the landscape of the textile industry. Their ability to handle dense materials with precision makes them essential tools that continue to adapt to the changing demands of modern manufacturing. As we look to the future, these machines are poised to embrace technological advancements that will further enhance their capabilities and impact, ensuring that they remain at the forefront of garment and textile production.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025