Advanced Techniques for Double Needle Stitching Machines in Textile Production

The Double Needle Stitching Machine Revolutionizing Textile Manufacturing

In the ever-evolving landscape of textile manufacturing, precision and efficiency are paramount. Among the plethora of tools developed to enhance the production process, the double needle stitching machine stands out as a pivotal innovation. This specialized machine has not only revolutionized garment production but has also improved the quality of finished products, thereby addressing the industry's increasing demand for durability and aesthetic appeal.

Understanding the Mechanism

At its core, the double needle stitching machine operates by simultaneously using two needles to create two parallel rows of stitches. This mechanism is supported by a single set of feed dogs, which guide the fabric through the machine. The dual-needle design allows for various stitch types, including straight, zigzag, and decorative stitches. Such versatility makes it an invaluable asset in both industrial and small-scale sewing operations.

The configuration of the double needle stitching machine differs from conventional single-needle machines, mainly in its complexity and versatility. With the ability to use multiple thread types, including elastic and heavy-duty threads, it can cater to a diverse range of applications, from lightweight fabrics to thick materials like denim and canvas.

Benefits of Double Needle Stitching

One of the primary benefits of utilizing a double needle stitching machine is the enhanced seam strength it provides. The two parallel rows of stitching create a more robust seam compared to single-thread stitching, which is essential in garments subjected to stress, such as sportswear or work uniforms. This added strength directly contributes to the lifespan of the product, reducing the risk of seam failure over time.

Moreover, double needle stitching also enhances the aesthetic qualities of the finished item. The two lines of stitching can create a visually appealing finish that adds an element of design and professionalism to garments. In fashion, where presentation is crucial, the ability to produce a clean and polished look can distinguish manufacturers in a competitive market.

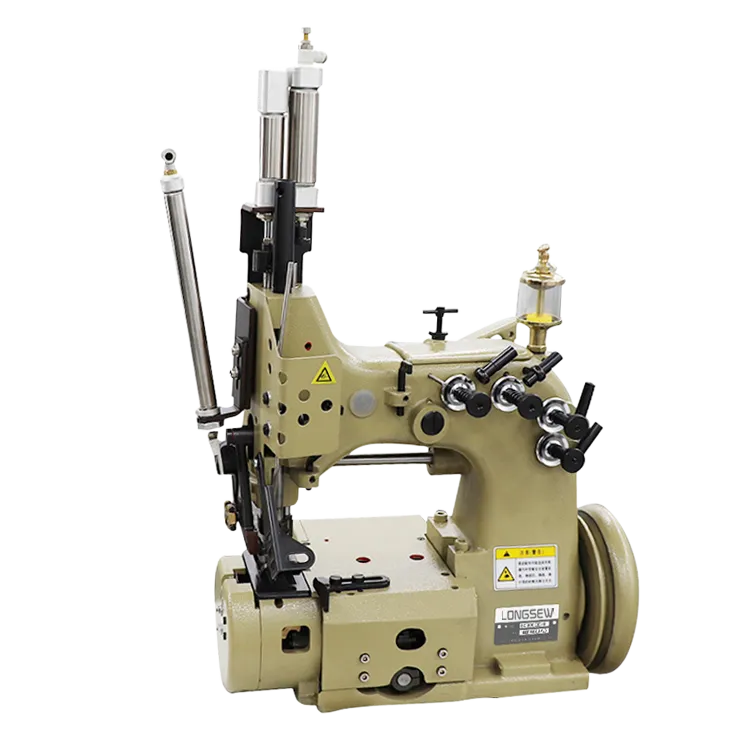

double needle stitching machine

Applications Across Industries

Double needle stitching machines are widely utilized across various sectors. In the apparel industry, they are indispensable for producing casual wear, activewear, and denim products. The automotive upholstery sector also benefits significantly from this technology, as it allows for the creation of durable and stylish seat covers and interiors. Other industries, such as furniture and home textiles, implement double needle stitching for similar reasons, combining function with fashion.

The machine’s ability to handle different fabric types makes it a versatile tool for manufacturers. It can accommodate everything from lightweight linens to heavy canvas, which means it can support a wide range of product lines without requiring extensive adjustments or changes in equipment, thus streamlining production processes.

Technological Advancements and Future Prospects

As technology continues to advance, so does the efficiency and functionality of double needle stitching machines. Modern innovations have introduced features such as computerized control systems, which allow for precise stitch length and tension adjustments. These advancements ensure that quality remains consistent, reducing the likelihood of errors that can arise from manual settings.

Furthermore, the rise of automation in the textile industry has prompted the integration of double needle stitching machines into larger, automated production lines. This integration not only enhances production speed but also significantly reduces labor costs, allowing manufacturers to respond more rapidly to market demands.

In conclusion, the double needle stitching machine represents a significant leap forward in textile manufacturing technology. Its combination of strength, aesthetic appeal, and versatility makes it an essential tool for producers aiming to meet the contemporary market's challenges. As the industry continues to evolve, the double needle stitching machine stands poised to play a crucial role in shaping the future of garment production. With ongoing advancements and a focus on sustainability, this machine will undoubtedly remain at the forefront of textile innovation for years to come.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025