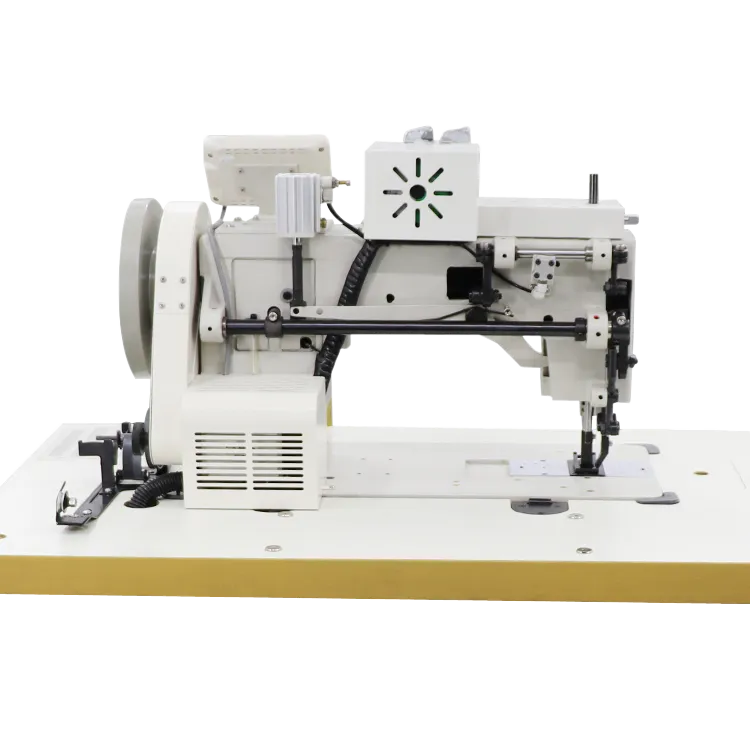

cnc upholstery sewing machine

The Rise of CNC Upholstery Sewing Machines Revolutionizing the Upholstery Industry

In recent years, the upholstery industry has witnessed a significant transformation, driven largely by advancements in technology. Among these innovations, CNC (Computer Numerical Control) upholstery sewing machines have emerged as a game-changer, reshaping the way upholstery work is performed. This article explores the features, benefits, and implications of integrating CNC sewing technology into upholstery manufacturing.

CNC upholstery sewing machines are advanced tools that automate the sewing process with high precision and efficiency. Unlike traditional sewing machines, which require manual operation, CNC machines are programmed to perform a variety of tasks with minimal human intervention. This technology leverages computer software to control the sewing pattern, stitch length, and sewing speed, ensuring consistent quality and precision in every project.

The Rise of CNC Upholstery Sewing Machines Revolutionizing the Upholstery Industry

Another benefit of CNC upholstery machines is the precision they offer. Upholstery work often involves intricate designs and patterns that require careful attention to detail. CNC technology enables the creation of complex shapes and patterns with high precision, resulting in cleaner cuts and more accurate seams. This level of quality is particularly valuable in high-end upholstery work, where aesthetic appeal and craftsmanship are paramount.

cnc upholstery sewing machine

Furthermore, CNC machines are equipped with advanced features such as automatic threading, digital display interfaces, and customizable programming options. Operators can easily input various design specifications and quickly switch between different sewing tasks without significant downtime. This flexibility allows businesses to respond promptly to changing customer demands and preferences.

The integration of CNC technology also has implications for sustainability in the upholstery industry. With precise cutting and sewing capabilities, wastage of materials is significantly reduced. Traditional methods often lead to excess fabric scraps, contributing to environmental waste. On the other hand, CNC machines can optimize material usage by accurately calculating and executing cuts, ultimately minimizing waste and lowering overall production costs.

Despite the numerous advantages, transitioning to CNC upholstery sewing machines does require investment in both equipment and training. Initial costs can be high, and companies must ensure that their workforce is adequately trained to operate and maintain these sophisticated machines. However, the long-term benefits—such as increased efficiency, reduced labor costs, and improved product quality—often outweigh these initial hurdles.

As CNC upholstery sewing machines become more accessible, we can expect a ripple effect throughout the industry. Smaller and medium-sized upholstery businesses can leverage this technology to compete with larger manufacturers, democratizing access to high-quality production techniques. This could lead to a renaissance in the upholstery industry, where craftsmanship meets cutting-edge technology.

In conclusion, CNC upholstery sewing machines represent a pivotal advancement in the upholstery industry. By enhancing production speed, precision, and sustainability, these machines are not only improving operational efficiency but also elevating the quality of upholstered products. As the industry continues to evolve, embracing CNC technology will undoubtedly play a crucial role in meeting the demands of modern consumers while preserving the artistry of upholstery work. The future looks promising as more businesses recognize the value of automation and innovation in their production processes.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025