cnc sewing

The Evolution and Importance of CNC Sewing Technology

In today’s fast-paced world of manufacturing, the integration of automation and precision technology into traditional processes has become paramount. One of the most significant innovations in the textile and apparel industry is the advent of Computer Numerical Control (CNC) sewing technology. This revolutionary approach has transformed how garments are produced, providing efficiency, consistency, and a level of customization that was previously unattainable.

What is CNC Sewing?

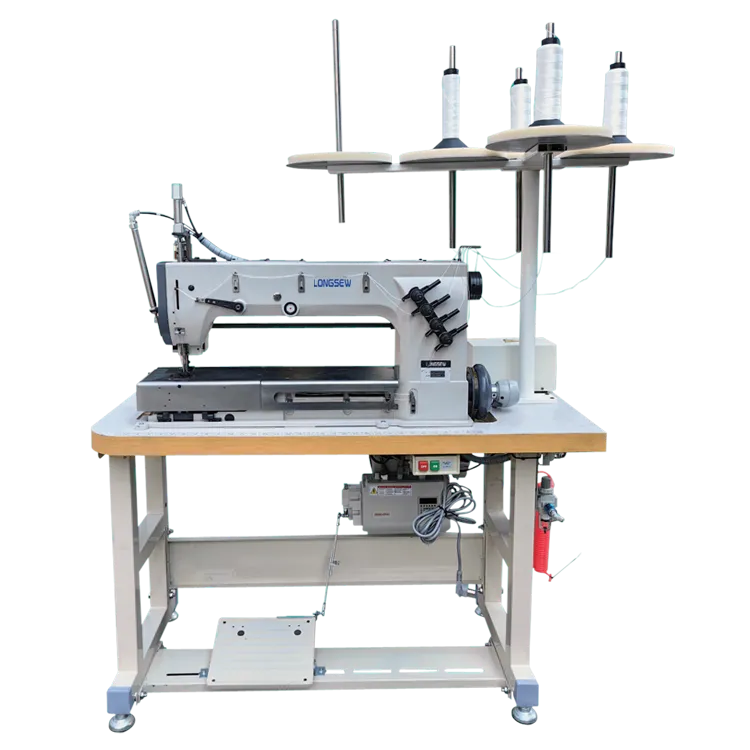

CNC sewing refers to the use of computer-controlled sewing machines to automate the sewing process. Unlike conventional sewing where a skilled operator dictates the movements, CNC sewing machines rely on programmed commands that dictate every stitch with incredible accuracy. This technology uses computer-aided design (CAD) software to create complex patterns and manage the sewing process, thus allowing for meticulous attention to detail.

The Advantages of CNC Sewing

1. Precision and Consistency One of the most significant advantages of CNC sewing is the precision it offers. The machines operate with a level of accuracy that surpasses human capability, ensuring that each piece produced matches the specifications exactly. This consistency is crucial in industries where high-quality standards must be maintained.

2. Efficiency CNC sewing machines can operate at speeds much higher than manual sewing, drastically reducing production times. This increase in efficiency means that companies can fulfill larger orders quicker, thereby meeting market demands faster and reducing lead times.

3. Reduced Labor Costs While the initial investment in CNC technology might be substantial, the reduction in labor costs over time is undeniable. Automated machines require fewer operators, and the efficiency of the machines means that less time is spent on production, ultimately lowering the overall cost of manufacturing.

4. Customization and Flexibility CNC sewing allows for a high degree of customization. Businesses can easily modify designs and produce small runs of tailored garments without needing extensive retooling. This adaptability is especially beneficial in a market that increasingly demands personalized products.

cnc sewing

5. Minimized Waste With precise cutting and sewing, CNC technology significantly reduces fabric waste. The algorithms used in CNC machines can optimize fabric usage, ensuring that the maximum number of pieces is cut and sewn from each roll of material. This not only benefits manufacturers financially but also supports sustainable practices in the industry.

The Implementation of CNC Sewing in Different Industries

CNC sewing technology extends beyond just garment manufacturing. It plays a critical role in various sectors, including upholstery, automotive, aerospace, and medical textiles. In the automotive industry, for example, CNC machines are employed to create upholstery and other fabric components with exact specifications necessary for safety and performance. In aerospace, where weight and precision are crucial, CNC sewing provides materials that meet stringent regulations.

Challenges and Future Perspectives

Despite its numerous advantages, the adoption of CNC sewing technology has its challenges. The initial cost of equipment can be a barrier for small manufacturers. Additionally, there is a need for skilled programmers who can operate the CNC machines and software effectively. Training workers to transition from traditional sewing techniques to automated processes requires a significant investment in time and resources.

Looking toward the future, advancements in technology such as artificial intelligence and machine learning could further enhance CNC sewing capabilities. The integration of smart technologies could enable machines to make real-time adjustments, predict maintenance needs, and even learn from past production runs to optimize future ones.

Conclusion

CNC sewing technology represents a significant paradigm shift in the textile and apparel industry. Its ability to deliver precision, efficiency, and customization responds to the growing demands of today’s market while minimizing waste and labor costs. As manufacturers adopt this technology, the future of textile production looks promising, balancing innovation with sustainability. The potential for further advancements only amplifies the importance of embracing CNC sewing in modern manufacturing processes, ensuring that the industry is well-equipped to meet the challenges and opportunities that lie ahead.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025