Exploring the Versatility and Applications of Chain Stitching Machines in Textile Industry

The Art and Functionality of Chain Stitching Machines

In the world of textile production and garment manufacturing, chain stitching machines play a crucial role in creating durable and flexible seams. These machines are essential for both industrial applications and artisanal crafts, enabling a range of stitching techniques that enhance the aesthetic and functional qualities of fabric. Understanding the operation and significance of chain stitching machines can provide insights into their continued relevance in the fashion and textile industries.

The Mechanism of Chain Stitching

Chain stitching machines operate using a series of interconnected loops created by two threads a top thread and a bottom thread, which forms a lock or chain stitch. This type of stitch stands out for its elasticity and strength, making it ideal for various types of fabrics, especially those that experience significant tension, such as knit materials. Unlike traditional lock-stitch machines, which use a bobbin under the needle plate, chain stitching machines typically rely on a looper mechanism to catch the needle thread, resulting in a strong, interlocked stitch.

The most common type of chain stitch is the single-thread chain stitch, designated as Class 200 in the International Sewing Machinery Standard. This stitch is often used in applications such as hemming, attaching lace, and other decorative stitching, as it can create a visually appealing finish. Multi-thread chain stitches provide even greater durability, as they use multiple threads to form thicker, reinforced seams that can withstand more strain.

Applications of Chain Stitching Machines

The versatility of chain stitching machines makes them suitable for various applications across multiple industries. In garment manufacturing, they are frequently used to join fabric pieces, make seams, and finish edges. Because of their durability and elasticity, chain stitches are ideal for creating sportswear, denim, and other high-stress garments that require robust stitching to maintain integrity under movements and washes.

In addition to clothing, chain stitch machines are widely used in home textiles, upholstery, and even in specialized areas such as leatherworking. The decorative capabilities of chain stitches lend themselves beautifully to crafting intricate designs on fabric, which is particularly popular in quilting and embroidery projects. Artisans often leverage chain stitching not only for its strength but also to enhance the visual appeal of their work.

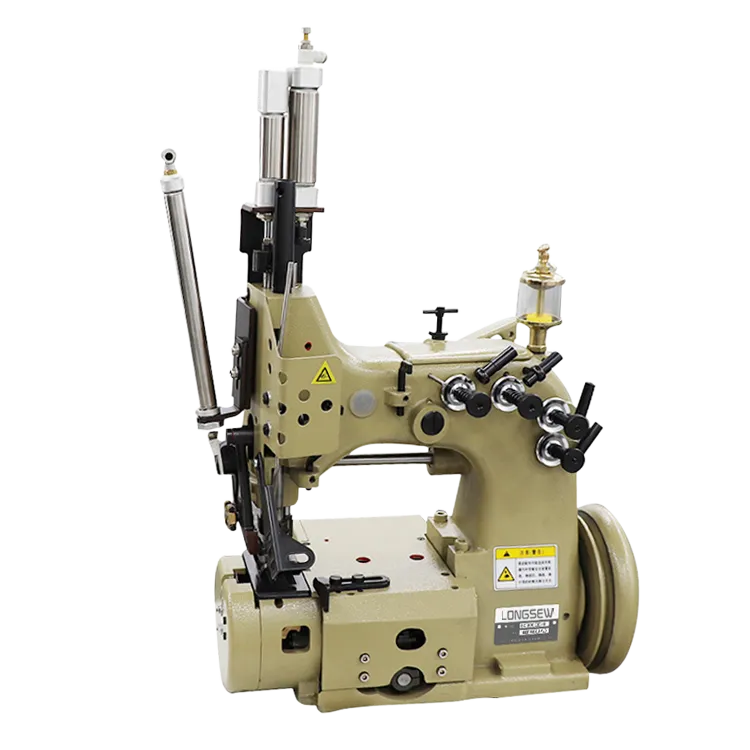

chainstitching machine

Advantages of Chain Stitching

One significant advantage of chain stitching is its capacity for “seam allowance,” which allows for the adjustment and alteration of garments after initial construction. Unlike traditional stitches that may be more challenging to unravel, chain stitches can be removed neatly, making the alteration process easier for tailors and seamstresses. Additionally, because chain stitches do not have the same risk of popping under tension as other stitch types, they can provide long-lasting durability.

Moreover, chain stitching machines are relatively easy to maintain. Their design simplifies access to various components, allowing for routine cleaning and adjustments without extensive downtime. This durability translates into efficiency for manufacturers, who use these machines to produce high volumes of products with consistent quality.

The Future of Chain Stitching Machines

As technology advances, the landscape of sewing machinery continually evolves. While computerized sewing machines are becoming increasingly popular in the industry for their speed and precision, chain stitching machines remain favored for specific applications requiring unique stitch types. Innovations in automation, such as the incorporation of robotics and smart technologies, are being integrated into traditional chain stitching designs, further increasing their efficiency and versatility.

Environmental concerns are also shaping the industry, with sustainable practices becoming a primary focus. Chain stitching machines, particularly those that use organic or recycled materials, are becoming essential for eco-friendly manufacturing processes. As the demand for sustainable solutions rises, the ability of chain stitching machines to produce strong products from sustainable fabrics positions them well for future market trends.

In conclusion, chain stitching machines are a fundamental component of modern textile production, offering versatility, durability, and aesthetic possibilities. Their ability to produce strong and flexible seams makes them indispensable across various fabric applications. As technology continues to advance, the evolution of chain stitching machines will undoubtedly enhance their function and broaden their applications in the fashion and textile industries.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025