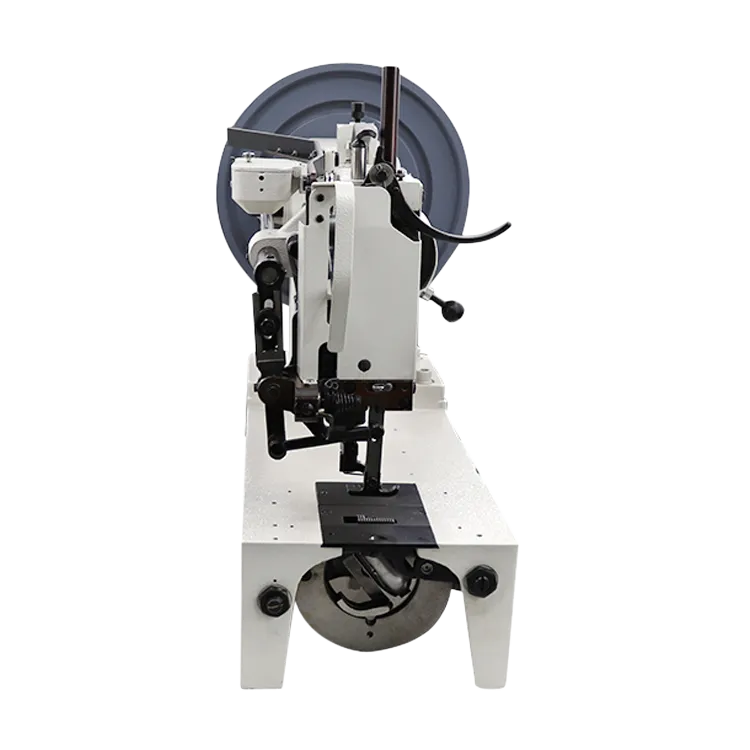

big bag auto machine

The Big Bag Auto Machine Revolutionizing Bulk Packaging Solutions

In industries where efficiency and productivity are paramount, the necessity for advanced packaging solutions cannot be overstated. Among these innovations, the Big Bag Auto Machine stands out as a game-changer. Designed to automate the bulk packaging process, this machine has transcended traditional methods, offering unmatched speed, precision, and reliability for businesses dealing with large quantities of products.

At the core of the Big Bag Auto Machine’s functionality is its capacity to handle significant volumes of materials quickly. This is particularly beneficial for industries such as agriculture, chemicals, construction, and food processing, where large bags—commonly referred to as bulk bags or FIBCs (Flexible Intermediate Bulk Containers)—are standard. These bags can hold anywhere from 500 up to 2,000 kilograms of product, making them ideal for shipping and storage. The automation aspect of this machine not only streamlines the packing process but also minimizes the need for manual labor, thereby reducing human error and enhancing overall safety.

The Big Bag Auto Machine Revolutionizing Bulk Packaging Solutions

Efficiency is further enhanced through the machine's high-speed operation. Depending on the model and configuration, a Big Bag Auto Machine can fill multiple bags in mere minutes, significantly reducing bottlenecks in production lines. For factories producing large quantities of goods, this increase in speed translates directly into higher output and better profit margins. Additionally, the integration of conveyor systems and automated sealing processes ensures a continuous flow of operations, minimizing downtime and enhancing productivity.

big bag auto machine

Moreover, the Big Bag Auto Machine is not just about speed; it's also about adaptability. With the rapid evolution of market demands, businesses must remain agile to meet the ever-changing needs of consumers. The automation tolerances allow for quick adjustments in filling parameters, ensuring that companies can switch between products with minimal disruption. This flexibility is invaluable for businesses that experience fluctuating demands or seasonal changes in production.

The sustainability aspect of using a Big Bag Auto Machine also deserves attention. By automating the packing process, companies may reduce their carbon footprint due to less manual handling and improved efficiencies in logistics. Furthermore, the machine can work with eco-friendly materials that comply with increasing environmental regulations, allowing companies to align with sustainability goals while maintaining a competitive edge in their market.

Investment in a Big Bag Auto Machine ultimately leads to a better return on investment (ROI). The initial costs associated with purchasing and installing such a system are quickly offset by the benefits of increased efficiency, reduced labor costs, and minimized waste. As more businesses move towards automation, those who invest in technology like the Big Bag Auto Machine will find themselves at the forefront of industry advancement.

In conclusion, the Big Bag Auto Machine is more than just a piece of equipment; it's a transformative solution that addresses many of the challenges faced by industries dealing with bulk materials. As technology continues to evolve, those who embrace automation will not only enhance their operational capabilities but also set new standards for efficiency and sustainability in packaging. The future of bulk packaging has arrived, and it’s encapsulated in the capabilities of the Big Bag Auto Machine.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025