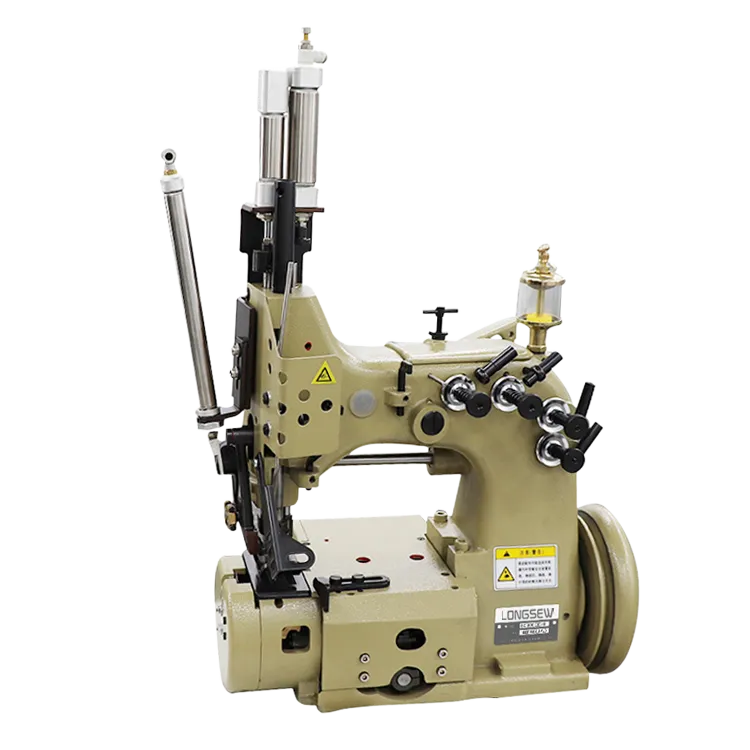

bags closer sewing machine

Bags Closer Sewing Machine Revolutionizing the Bag Manufacturing Industry

In the world of manufacturing, efficiency and precision are paramount, especially when it comes to producing items that meet high-quality standards. The bags closer sewing machine has emerged as a vital piece of equipment in the bag manufacturing industry, offering significant advancements in speed, reliability, and versatility. This article will explore the importance of bags closer sewing machines, their functionality, and their impact on the industry.

A bags closer sewing machine is specifically designed for closing the seams of various types of bags, including those made from fabric, polypropylene, and paper. These machines are engineered to facilitate the rapid and secure closure of bags used for packaging goods from grains to chemicals, thereby enhancing productivity in manufacturing processes. Traditional sewing methods often proved time-consuming and inconsistent, leading to higher labor costs and the potential for human error. With the advent of specialized bags closer sewing machines, manufacturers can achieve a more streamlined operation, resulting in significantly improved quality control.

The functionality of bags closer sewing machines is centered around their ability to handle different materials and bag types

. Most modern machines feature adjustable settings for stitch length and tension, allowing operators to customize their approach based on the bag's specifications. Additionally, many models are equipped with automatic features, such as thread cutting and bag positioning, which reduce the need for manual intervention and further decrease production time.bags closer sewing machine

One of the notable advantages of bags closer sewing machines is their versatility. These machines can be used in various industries, including agriculture, food packaging, industrial manufacturing, and retail. This adaptability makes them an invaluable asset in a competitive market where manufacturers must remain agile to meet changing consumer demands. Furthermore, the machines can be adapted for different bag styles, such as open-mouth or pillow-type bags, ensuring that manufacturers can cater to a diverse range of products.

The impact of bags closer sewing machines on the bag manufacturing industry is profound. By automating the bag closing process, manufacturers can increase their output without sacrificing quality. Higher production rates often lead to reduced costs, allowing companies to offer competitive pricing to their customers. Additionally, the consistent quality provided by these machines helps to elevate brand reputation, as consumers increasingly demand reliable and well-made products.

In conclusion, the bags closer sewing machine represents a significant advancement in the bag manufacturing sector. Its ability to enhance efficiency, reduce labor costs, and provide consistent quality has transformed how manufacturers approach bag production. As industries continue to evolve, the importance of incorporating innovative machinery will only continue to grow, ensuring that manufacturers remain competitive in a fast-paced global market. With the ongoing advancements in technology, the future looks bright for bags closer sewing machines and the broader manufacturing industry.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025