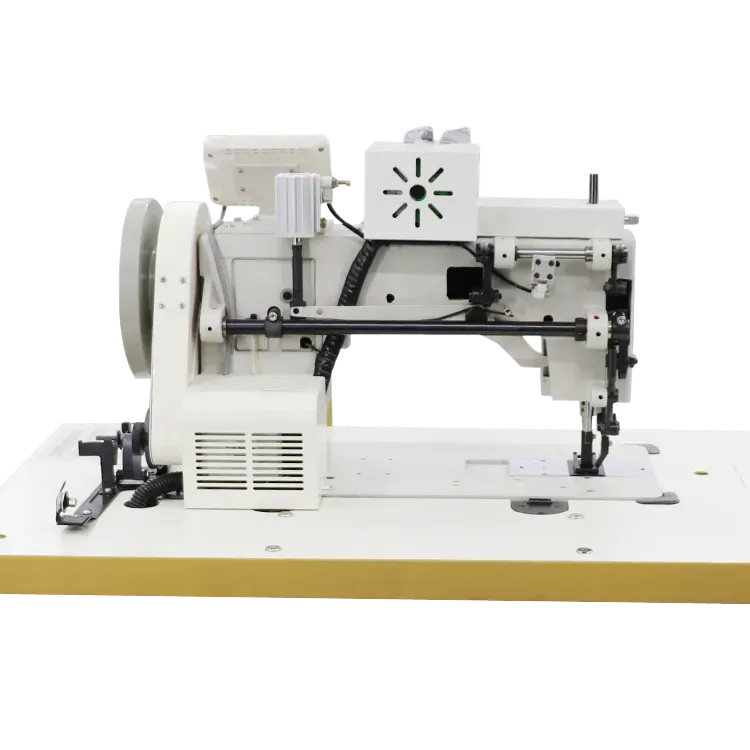

bag closer machine with conveyor system

The Evolution and Importance of Bag Closer Machines with Conveyor Systems

In modern manufacturing and packaging industries, efficiency and precision are paramount. Among the array of machines designed to streamline operations, the bag closer machine with a conveyor system stands out as an essential tool that enhances productivity and ensures the quality of packaged goods. This advanced machinery plays a critical role in various sectors, including food and beverage, pharmaceuticals, agriculture, and industrial manufacturing.

A bag closer machine is designed to seal various types of bags, whether they are made from paper, plastic, or other materials. The primary purpose of this machine is to ensure that the bags are securely closed to protect the contents from contamination, spillage, and environmental factors. With the growing demand for packaged products, the importance of efficient sealing systems has never been more significant.

The integration of a conveyor system with bag closer machines brings numerous advantages. The conveyor system acts as a transportation mechanism that facilitates the smooth movement of bags from one stage of the operation to another. This seamless transition is crucial in a production line, where minimizing downtime and maintaining a steady flow of products are vital for maximizing output.

One of the most significant benefits of using a bag closer machine with a conveyor system is the increase in productivity. Manual bag sealing is labor-intensive and time-consuming, often leading to inconsistent results. In contrast, automated machines ensure uniformity in sealing, significantly reducing the time taken for each bag. The conveyor system supports this efficiency by continually feeding the bags into the closer machine, allowing for an uninterrupted workflow.

Moreover, the combination of these machines reduces labor costs. In industries where manual work can lead to fatigue and human error, automation helps mitigate these risks. By employing a bag closer machine with a conveyor system, companies can allocate their workforce to other critical tasks, thus optimizing labor distribution and minimizing operational costs.

bag closer machine with conveyor system

Quality control is another advantage of using a bag closer machine integrated with a conveyor system. These machines are equipped with advanced technology that allows for precise sealing techniques. Different types of seals—such as heat seals, stitch seals, or adhesive seals—can be implemented depending on the nature of the packaging and its contents. This adaptability ensures that products remain intact and meet safety standards, which is particularly crucial in industries such as food and pharmaceuticals, where product integrity is paramount.

Moreover, today’s bag closer machines are often equipped with sensors and automated features that monitor the sealing process in real-time. This technology detects any irregularities, allowing for immediate adjustments, thus minimizing wastage and ensuring every bag is sealed correctly.

Sustainability has also become an essential factor in modern manufacturing practices. Bag closer machines can be designed to work with eco-friendly packaging materials, aligning with the global push towards sustainability. Additionally, the efficient use of materials and reduction in wastage contribute to a more sustainable production cycle.

As industries continue to evolve, the future of bag closer machines with conveyor systems looks promising. Ongoing advancements in technology, including the incorporation of artificial intelligence and machine learning, are set to further enhance the capabilities of these machines. Predictive maintenance features will likely be introduced, enabling companies to anticipate and address potential breakdowns, thus avoiding delays in production.

In conclusion, the bag closer machine with a conveyor system is an indispensable asset in the modern manufacturing and packaging landscape. Its ability to combine efficiency, precision, and versatility makes it an ideal solution for businesses aiming to streamline their operations. As technology continues to advance, these machines will only become more sophisticated, enabling companies to meet the ever-increasing demands of consumers while adhering to stringent quality and environmental standards. Embracing such innovations will undoubtedly contribute to the success and sustainability of industries worldwide.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025