Bag Closing Solutions | Secure & Efficient Bag Sealing Equipment

The Importance of Bag Closing Groups in Packaging

In today's fast-paced manufacturing environment, efficiency and precision are key to maintaining competitive advantage. One area that often requires attention is the bag closing process, which is critical in industries ranging from food packaging to pharmaceuticals. Central to this process is the concept of a bag closing group, an assembly of tools and machinery designed to ensure bags are securely sealed after they have been filled with products.

A bag closing group typically consists of various components, including sealers, stitchers, and heat sealers. These tools work together to create a tight closure that prevents leakage, contamination, and spoilage. The choice of equipment within the closing group varies based on the type of bag and the product being packaged. For instance, food items may require heat sealing to ensure freshness, while heavy-duty industrial products might need stitching for durability.

One of the primary benefits of implementing an efficient bag closing group is enhanced productivity

. Automated systems can significantly reduce the time taken to seal bags compared to manual methods. With the ability to process large volumes in a short amount of time, companies can increase their output and meet growing demand without compromising quality.Moreover, a well-designed bag closing group contributes to the reduction of waste. When bags are properly sealed, the risk of product loss due to damage or spoilage is minimized. This is especially important in the food sector, where safety standards are stringent, and any product that becomes contaminated can lead to significant financial losses and health risks.

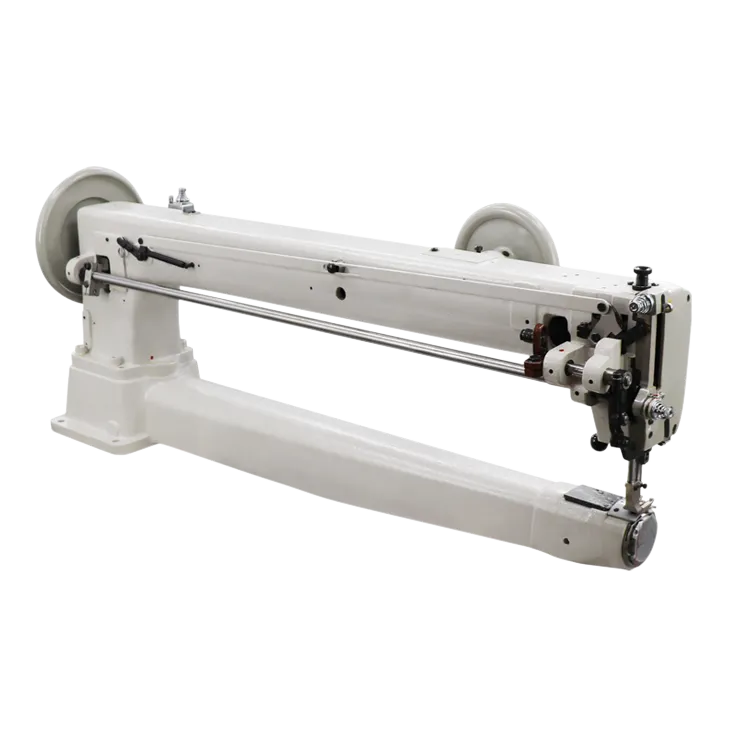

bag closing group

Another critical aspect of bag closing groups is their versatility. Different industries have diverse packaging requirements, and modern bag closing systems can be adapted to meet these needs. Whether dealing with plastic, paper, or biodegradable materials, manufacturers can choose closing methods that align with their sustainability goals and compliance regulations.

In addition to operational efficiency and waste reduction, the use of advanced technology in bag closing systems enhances quality control. Many modern sealers are equipped with sensors and automated feedback systems that monitor sealing strength and integrity in real-time. This not only ensures a consistent product but also allows for immediate adjustments, thereby preventing issues that could lead to customer dissatisfaction.

Ultimately, investing in a robust bag closing group is essential for any company that relies on packaging as a means of protecting and presenting its products. With the right tools and techniques, businesses can ensure their products are secure, maintain high standards of quality, and operate efficiently. As industries continue to evolve and demand for innovative packaging solutions grows, the importance of effective bag closing systems will only increase.

In conclusion, the bag closing group plays a pivotal role in the packaging process. By focusing on efficiency, waste reduction, versatility, and quality control, companies can optimize their operations and provide better value to their customers. Whether in food, pharmaceuticals, or industrial applications, the integrity of a product often hinges on how well it is sealed, making bag closing groups indispensable in modern manufacturing.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025