Feb . 05, 2025 03:06

Back to list

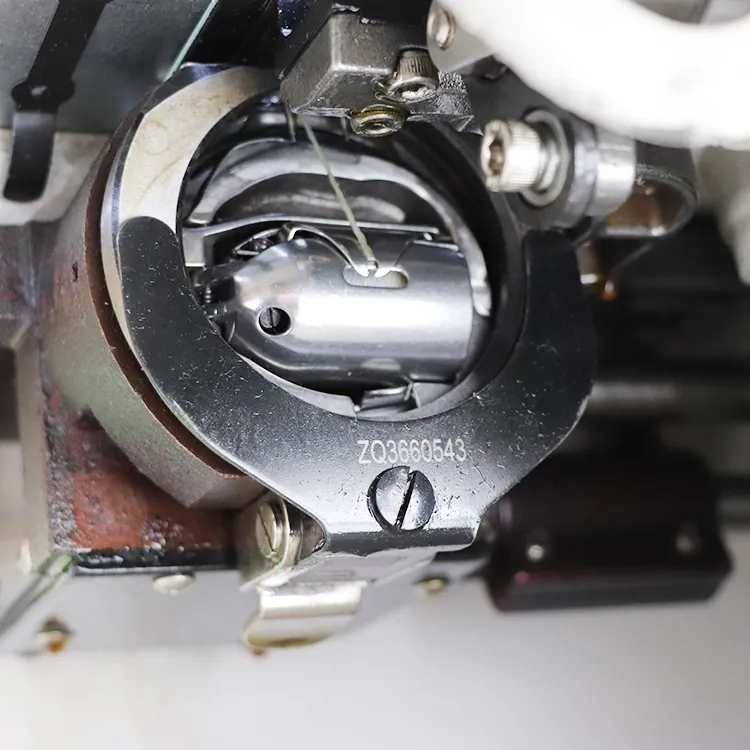

chain stitch sewing machine

Automation in the sewing industry is transforming the way clothing, upholstery, and other textile goods are produced, bringing about a revolution that is as much about the quality and precision of output as it is about efficiency. An automated sewing machine integrates advanced robotic technology with sewing mechanics to vastly improve productivity, establishing itself as an indispensable tool for modern manufacturers.

Trustworthiness in automated sewing technology comes from its proven track record across various industries. Brands that have adopted this technology often see a noticeable boost in product quality and production efficiency. This reliability is not only a testament to the robust engineering behind these machines but also reflects the comprehensive support offered by manufacturers, who provide extensive service agreements, updates, and training to keep operations seamless. Furthermore, as sustainability becomes a priority, automated sewing machines contribute positively. The precision of these machines results in less wastage of materials. Accurate cutting and stitching mean fewer errors that require additional fabric consumption, a big win for eco-conscious manufactures striving to reduce their environmental footprint. Automation also enhances safety within sewing operations. The machinery takes over the most repetitive and labor-intensive tasks, mitigating worker fatigue and the risk of injuries that can occur with manual sewing. This shift not only creates a safer working environment but also allows human workers to focus on more complex, less monotonous tasks, which can lead to increased job satisfaction and productivity. Adopting automated sewing technology isn't without challenges. Initial costs can be high, and transitioning from traditional methods requires a strategic approach to change management. However, the long-term benefits—improved quality, enhanced efficiency, and sustainability—outweigh these initial hurdles for many companies. In conclusion, automation in sewing is more than a technological upgrade; it represents a fundamental change in the manufacturing landscape. By delivering unmatched precision and efficiency, automated sewing machines are paving the way for the next generation of textile production. Companies that can harness this technology effectively will not only stay competitive but also lead the charge in innovation, setting new benchmarks in quality and sustainability within the industry.

Trustworthiness in automated sewing technology comes from its proven track record across various industries. Brands that have adopted this technology often see a noticeable boost in product quality and production efficiency. This reliability is not only a testament to the robust engineering behind these machines but also reflects the comprehensive support offered by manufacturers, who provide extensive service agreements, updates, and training to keep operations seamless. Furthermore, as sustainability becomes a priority, automated sewing machines contribute positively. The precision of these machines results in less wastage of materials. Accurate cutting and stitching mean fewer errors that require additional fabric consumption, a big win for eco-conscious manufactures striving to reduce their environmental footprint. Automation also enhances safety within sewing operations. The machinery takes over the most repetitive and labor-intensive tasks, mitigating worker fatigue and the risk of injuries that can occur with manual sewing. This shift not only creates a safer working environment but also allows human workers to focus on more complex, less monotonous tasks, which can lead to increased job satisfaction and productivity. Adopting automated sewing technology isn't without challenges. Initial costs can be high, and transitioning from traditional methods requires a strategic approach to change management. However, the long-term benefits—improved quality, enhanced efficiency, and sustainability—outweigh these initial hurdles for many companies. In conclusion, automation in sewing is more than a technological upgrade; it represents a fundamental change in the manufacturing landscape. By delivering unmatched precision and efficiency, automated sewing machines are paving the way for the next generation of textile production. Companies that can harness this technology effectively will not only stay competitive but also lead the charge in innovation, setting new benchmarks in quality and sustainability within the industry.

Previous:

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025