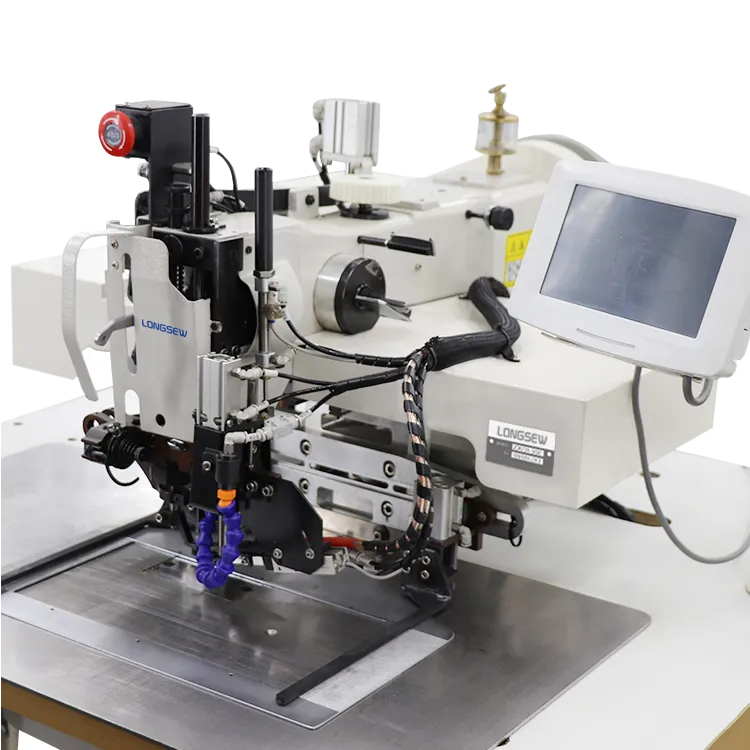

automatic bag closer machine

The Automatic Bag Closer Machine Revolutionizing Packaging Efficiency

In today's fast-paced production environment, efficiency, speed, and reliability are crucial for businesses aiming to thrive. One of the key components that have emerged to enhance operational productivity is the automatic bag closer machine. This innovative equipment plays a vital role in various industries, including food processing, agriculture, and manufacturing, by streamlining the packaging process and ensuring consistency in quality.

An automatic bag closer machine is designed to seal bags securely after they have been filled with products. The machine operates through a series of automated processes that require minimal human intervention, making it an essential asset for any production line. These machines are capable of closing a wide array of bag types, including paper, plastic, and woven bags, catering to diverse packaging needs.

Key Features and Benefits

One of the primary advantages of using an automatic bag closer machine is its speed. Traditional manual methods of bag sealing can be time-consuming and labor-intensive. In contrast, automatic machines can seal bags at a significantly faster rate, which enhances overall productivity. Many models can achieve sealing rates of up to 20-30 bags per minute, allowing companies to keep pace with high-demand situations.

Reliability is another important feature of automatic bag closers. These machines are designed to operate consistently under various conditions. With advanced technology, they are capable of detecting faulty seals and ensuring that every bag is properly closed, reducing the risk of leaks and contamination. This is especially critical in industries such as food processing, where product quality and safety are paramount.

automatic bag closer machine

Automatic bag closer machines also reduce labor costs. By minimizing the need for manual labor in the sealing process, companies can allocate their workforce more efficiently and focus on other essential tasks. This not only saves money but also helps in maintaining a safer work environment by reducing workplace injuries associated with manual sealing methods.

Versatility and Customization

The versatility of automatic bag closer machines is another notable benefit. Many models can be customized to accommodate different bag sizes and materials, making them suitable for various applications. Whether a business needs to package pet food, grains, chemicals, or consumer goods, there’s likely an automatic bag closer that fits their requirements.

Additionally, some machines offer programmable features that allow users to set specific sealing parameters, including temperature and pressure, ensuring that each bag is sealed optimally based on the material and product it contains. This adaptability makes automatic bag closers an excellent investment for businesses looking to diversify their product offerings.

Conclusion

In conclusion, the automatic bag closer machine is a game-changer in the packaging industry. Its ability to enhance speed, reliability, and cost-effectiveness makes it an indispensable tool for businesses aiming to improve their operational efficiency. As industries continue to evolve and the demand for high-quality packaging solutions grows, automatic bag closer machines will undoubtedly play a pivotal role in shaping the future of packaging processes. Investing in this technology not only improves productivity but also contributes to overall product quality and customer satisfaction, ensuring long-term success in a competitive marketplace.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025