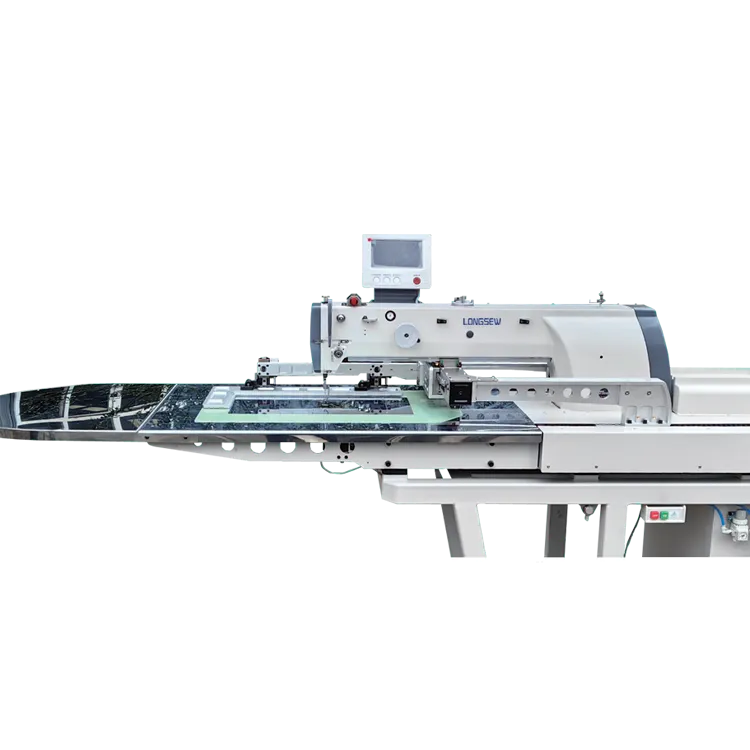

automated sewing machine

The Evolution and Impact of Automated Sewing Machines

The world of textile manufacturing and garment production has undergone a transformative shift with the introduction of automated sewing machines. These sophisticated devices have revolutionized the industry, enhancing efficiency, precision, and consistency. The advent of automation in sewing not only streamlines production processes but also significantly affects labor dynamics, quality control, and innovation in design.

Automated sewing machines, often equipped with advanced technology such as computer numerical control (CNC), programmable logic controllers (PLC), and robotics, enable high-speed sewing with remarkable accuracy. Unlike traditional sewing machines, which rely heavily on manual labor, these automated systems can operate continuously, producing an extensive volume of garments in a shorter timeframe. This capability is particularly crucial in meeting the demands of fast fashion, where speed to market is essential.

The precision of automated sewing machines is another critical advantage. With the ability to replicate complex stitching patterns and maintain consistent quality across numerous products, these machines minimize the risk of human error. This reliability is vital for brands seeking to uphold their reputation for quality while managing the pressures of supply chain logistics. Consistency in stitching quality also reduces the likelihood of returns and increases customer satisfaction, thereby enhancing a brand's overall profitability.

automated sewing machine

Moreover, the implementation of automated sewing machines has led to a shift in labor dynamics within the industry

. While there is concern about job displacement as machines take over repetitive tasks, there is also an emerging need for skilled workers who can operate, program, and maintain these sophisticated systems. This change calls for a reevaluation of workforce training and development, ensuring that employees are equipped with the skills necessary to thrive in an increasingly automated environment.In addition to efficiency and quality, automated sewing machines foster innovation in garment design. Designers can experiment with intricate patterns and unconventional materials, knowing that modern machines can handle complex tasks that were once deemed impractical. This opens up new avenues for creativity, leading to unique products that can capture consumer interest in a competitive market.

The environmental impact of automated sewing machines cannot be overlooked. With enhanced efficiency, these machines can contribute to reduced material waste and lower energy consumption compared to traditional sewing methods. As the industry increasingly focuses on sustainability, automated systems can play a crucial role in creating eco-friendly manufacturing processes.

In conclusion, automated sewing machines represent a significant leap forward in the textile and garment industry. By improving efficiency, ensuring quality, transforming labor needs, fostering innovation, and promoting sustainability, these machines are shaping the future of fashion production. As the industry continues to evolve, it will be essential for stakeholders to embrace these changes while focusing on workforce development and sustainability initiatives to ensure a balanced approach to advancement.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025