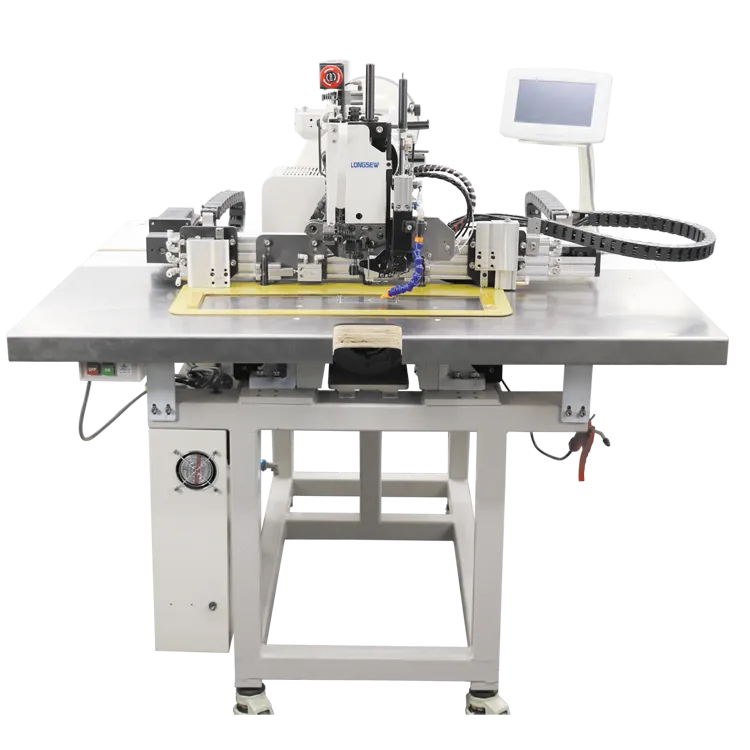

automated industrial sewing machine

Automated Industrial Sewing Machines Revolutionizing the Textile Industry

In recent years, the textile industry has undergone significant transformations, largely driven by advancements in technology. One of the most remarkable developments is the introduction of automated industrial sewing machines. These machines have redefined the way garments are produced, enhancing efficiency, precision, and overall output while reducing labor costs. This article explores the benefits, functionality, and future potential of automated industrial sewing machines.

The Evolution of Sewing Technology

The journey of sewing technology began in the 19th century with the invention of the first sewing machines. Over time, these machines evolved from manual, labor-intensive devices to sophisticated automated systems. Automated industrial sewing machines represent the pinnacle of this evolution, integrating computer technology and robotics to perform complex tasks with minimal human intervention.

These machines employ advanced features such as programmable logic controllers (PLCs), sensors, and artificial intelligence to optimize sewing processes. They can operate multiple threads simultaneously, allowing manufacturers to create intricate designs and patterns with remarkable speed and accuracy.

Benefits of Automated Industrial Sewing Machines

1. Increased Productivity One of the primary advantages of automated sewing machines is their ability to produce garments at an unprecedented pace. Manufacturers can achieve up to several thousand stitches per minute, significantly surpassing the capabilities of traditional sewing methods. This increased output can help meet the ever-growing demand for fast fashion and reduce lead times in production.

2. Enhanced Precision and Consistency Automated machines are designed to execute repetitive tasks with extreme precision. This consistency minimizes human error, ensuring that each garment meets the desired quality standards. As a result, manufacturers can enhance their product offerings, reduce waste, and improve their overall reputation in the market.

3. Cost-Effectiveness Although the initial investment in automated sewing systems may be substantial, the long-term savings can be significant. With reduced labor costs and increased production efficiency, companies can achieve a quicker return on investment. Additionally, lower production costs can make it possible to offer competitive pricing in the global market.

automated industrial sewing machine

4. Versatility and Customization Modern automated industrial sewing machines are highly versatile. They can be programmed to handle various fabrics, patterns, and styles, allowing manufacturers to cater to diverse market demands. Many machines also feature user-friendly interfaces that enable quick adjustments, making it easier to pivot in response to changing consumer preferences.

Challenges and Considerations

While the advantages of automated industrial sewing machines are clear, there are challenges to consider. The initial financial investment can be a barrier for smaller manufacturers. Furthermore, the implementation of automation may lead to job displacement for workers in the textile industry. Companies must navigate these challenges responsibly, focusing on reskilling workers and finding a balance between automation and human labor.

The Future of Automated Sewing Technology

Looking ahead, the future of automated industrial sewing machines is bright. Continuous advancements in artificial intelligence and machine learning are expected to further enhance the capabilities of these machines. The incorporation of smart technology will enable predictive maintenance, minimizing downtime and ensuring optimal performance.

Moreover, as sustainability becomes a primary focus for the textile industry, automated machines can contribute by minimizing waste through more accurate cutting and sewing techniques. The integration of technologies such as 3D printing and digital fabric printing may also open new avenues for creative expression while maintaining efficiency.

Conclusion

Automated industrial sewing machines are not just a technological innovation; they are a transformative force in the textile industry. With their ability to increase productivity, enhance accuracy, and reduce costs, these machines play a crucial role in meeting the demands of modern consumers. As technology continues to evolve, the potential for even more sophisticated automation in garment production is limitless, promising an exciting future for the industry. Manufacturers that embrace these advancements will position themselves advantageously in an increasingly competitive market.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025