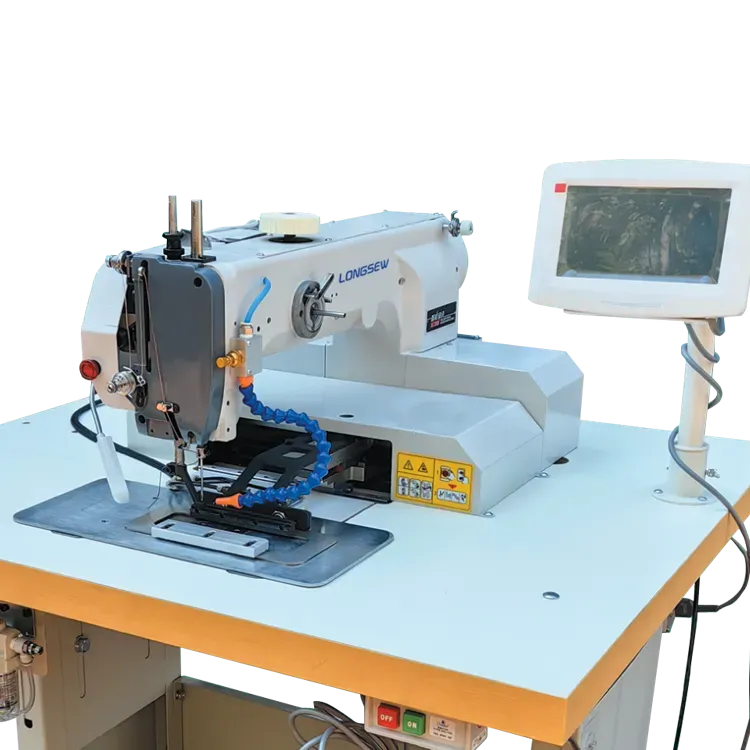

1 needle lockstitch sewing machine

Understanding the 1% Needle Lockstitch Sewing Machine

The 1% needle lockstitch sewing machine is a remarkable advancement in the realm of textile and garment manufacturing, combining traditional sewing mechanics with modern technology to enhance efficiency and precision. This type of sewing machine is primarily utilized in the production of clothing and other fabric-related products, making it a crucial component of the textile industry.

At its core, the lockstitch sewing machine operates on a simple yet effective principle it uses two threads to create a stitch that locks the fabric layers together. The needle thread and the bobbin thread interlock to form a durable seam, which is essential for both the aesthetic and functional aspects of sewn products. The 1% designation signifies a specific model or type within a broader category of lockstitch machines, denoting certain features or capabilities that distinguish it from others.

One of the key benefits of the 1% needle lockstitch sewing machine is its precision

. The machine is designed to provide even stitching with minimal fabric puckering, which is particularly important when working with lightweight or delicate fabrics. This level of precision ensures that garments fit well and maintain their shape, appealing to both manufacturers and consumers who value quality.Moreover, the 1% needle lockstitch machine often incorporates advanced features such as automatic thread tension adjustment, programmable stitch lengths, and various presser foot options. These enhancements not only improve the ease of use but also enable manufacturers to adapt the machine for different types of sewing tasks. For instance, some machines might be equipped with features that allow for decorative stitching, making them versatile tools for creative and custom garment production.

1 needle lockstitch sewing machine

In terms of efficiency, the 1% needle lockstitch sewing machine is optimized for speed. Many models can sew at remarkable rates, significantly increasing output in high-demand production environments. This efficiency is crucial for manufacturers aiming to meet tight deadlines and reduce labor costs. Additionally, with the incorporation of technological advancements, some machines feature computerized systems that allow for quick setup changes, reducing downtime and keeping production lines moving smoothly.

The maintenance of a 1% needle lockstitch sewing machine is also relatively straightforward. Routine maintenance tasks such as oiling the machine and replacing needles can be easily managed by operators, ensuring that the machine remains in good working condition over time. This reliability is essential for businesses that depend on industrial sewing machines to deliver consistent results day after day.

However, like any piece of equipment, the 1% needle lockstitch sewing machine has its limitations. It may not be suitable for all types of sewing applications—for example, it may struggle with very thick fabrics or specialized sewing tasks that require different techniques. Nevertheless, its versatility makes it a staple in many garment factories.

In conclusion, the 1% needle lockstitch sewing machine plays a vital role in the textile industry, combining precision, efficiency, and modern technology to revolutionize garment production. As it continues to evolve, we can expect even more innovative features that will further enhance its capabilities, ensuring that it remains a key tool for manufacturers around the world. Whether for mass production or bespoke tailoring, this machine exemplifies the perfect blend of tradition and innovation in crafting high-quality textile products.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025