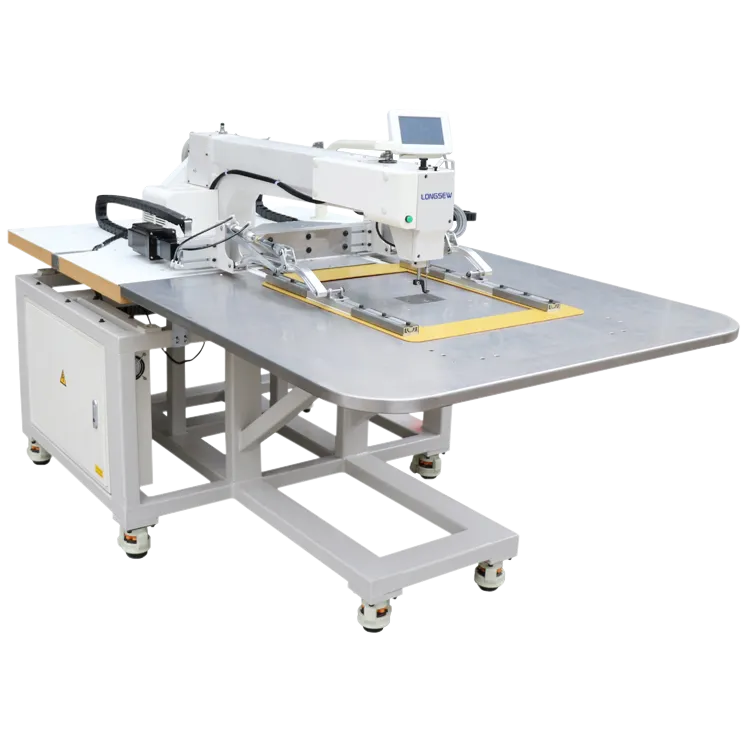

LS300-6050 FIBC Bag Sewing Machine|Bulk Packaging Efficiency&Precision

Advanced FIBC Bag Sewing Machine: Enhancing Efficiency in Bulk Packaging

Discover the revolutionary FIBC Bag Sewing Machine from Longsew, designed to transform your bulk packaging operations. This high-performance solution combines cutting-edge technology with precision engineering to deliver unmatched efficiency and reliability.

Revolutionizing Bulk Packaging with Intelligent Automation

Longsew's LS300-6050 Automatic Computerized Pattern Sewing Machine redefines bulk bag manufacturing through its advanced automation capabilities. This machine is specifically engineered for FIBC (Flexible Intermediate Bulk Container) bags, jumbo bags, and big bags, offering a comprehensive solution for industries requiring high-volume, precision packaging.

Key Features and Technical Specifications

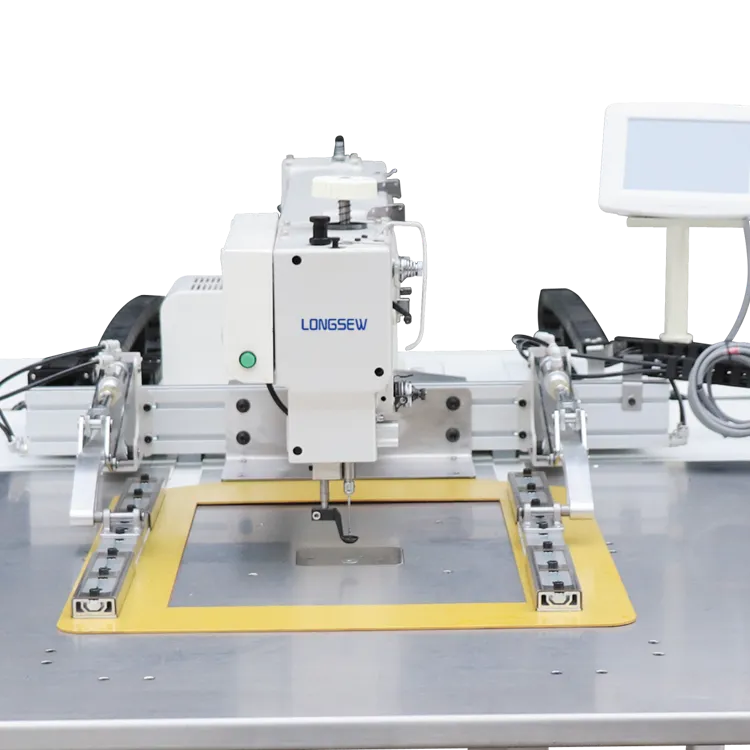

- Computerized Pattern Control: Ensures precise stitching patterns for consistent quality

- High-Speed Operation: Achieves up to 200-300 stitches per minute

- Multi-Functionality: Handles various bag sizes and configurations

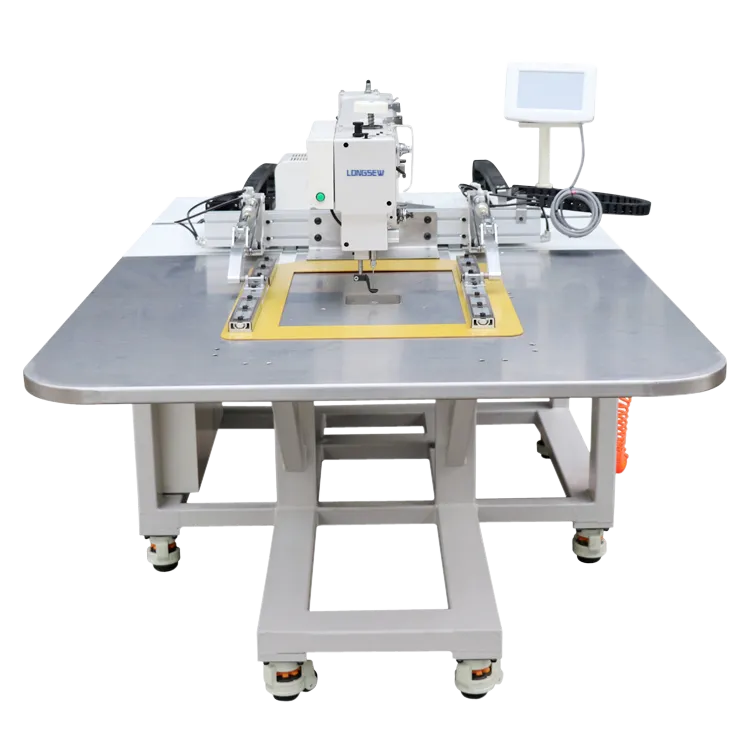

- Durable Construction: Heavy-duty frame for long-term industrial use

- User-Friendly Interface: Intuitive control panel for easy operation

Addressing Industry Challenges with Innovative Solutions

The traditional bulk bag manufacturing process often faces challenges such as:

- Manual labor-intensive operations

- Inconsistent stitching quality

- High production costs

- Time-consuming setup processes

Longsew's LS300-6050 machine directly addresses these issues through:

- Automated pattern recognition and stitching

- Advanced sensor technology for real-time quality control

- Energy-efficient design reducing operational costs

- Quick-change tooling system for rapid size adjustments

Why Choose Longsew for Your Packaging Solutions?

As a leading manufacturer in the packaging industry, Longsew has established itself as a trusted partner for businesses worldwide. Our commitment to innovation is reflected in our state-of-the-art facilities and rigorous quality control processes.

Technological Advancements

Our research and development team continuously improves our machines through:

- Patented stitching technology for enhanced durability

- AI-powered predictive maintenance systems

- Customizable software interfaces for different production needs

- Integration with Industry 4.0 smart manufacturing systems

Proven Performance in Real-World Applications

Customers across various industries have reported significant improvements in their operations:

"Since implementing the LS300-6050, our production efficiency has increased by 40% while reducing material waste by 25%." - John Doe, Manufacturing Director at ABC Industries

Key Benefits for Your Business

- Reduced labor costs through automation

- Consistent product quality with minimal defects

- Increased production capacity

- Enhanced safety features for operators

- Compliance with international packaging standards

Comprehensive Support and Services

We provide end-to-end support to ensure your success:

- Installation and Training: On-site setup and operator training programs

- Technical Support: 24/7 assistance from our expert team

- Warranty and Maintenance: Comprehensive service packages for long-term reliability

- Custom Solutions: Tailored configurations to meet specific production requirements

Environmental Responsibility and Safety Standards

Our machines are designed with sustainability in mind:

- Energy-efficient motors that reduce power consumption

- Non-toxic materials compliant with global safety regulations

- Recyclable components for eco-friendly disposal

- Comprehensive safety systems including emergency stop functions

Seamless Integration and Scalable Solutions

Whether you're a small manufacturer or a large-scale producer, our machines can be integrated into your existing production line or configured as a standalone unit. The LS300-6050 offers:

- Modular design for easy expansion

- Compatibility with various raw materials

- Scalable production capacity options

- Flexible configuration for different bag types

Ordering and Logistics

We offer professional packaging solutions to ensure safe transportation:

- Customized wooden crates for international shipping

- Comprehensive insurance options

- Real-time tracking system for all shipments

- Compliance with all relevant international shipping regulations

FAQs

What makes the LS300-6050 different from other sewing machines?

The LS300-6050 combines advanced computerized pattern control with high-speed automation, offering unparalleled precision and efficiency compared to traditional models.

Can the machine handle different bag sizes?

Yes, the machine features a quick-change tooling system that allows for easy adjustments to accommodate various bag dimensions.

What kind of maintenance is required?

Regular cleaning, lubrication of moving parts, and periodic inspection of electrical components are recommended. Our maintenance package includes scheduled servicing and technical support.

Is training provided for operators?

Yes, we offer comprehensive training programs including on-site installation, operation manuals, and video tutorials to ensure your team can use the machine effectively.

What is the warranty period?

The machine comes with a 12-month warranty covering all parts and labor. Extended warranty options are available upon request.

Contact Us for a Free Consultation

Ready to upgrade your packaging operations? Contact Longsew today for a personalized solution:

- Phone: +86 138-XXXX-XXXX

- Email: sales@longsew.com

- Website: www.longsew.com

- Live Chat: Start Chat

Transform your bulk packaging process with Longsew's LS300-6050 Automatic Computerized Pattern Sewing Machine. Experience the future of efficient, high-quality bag manufacturing today.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025